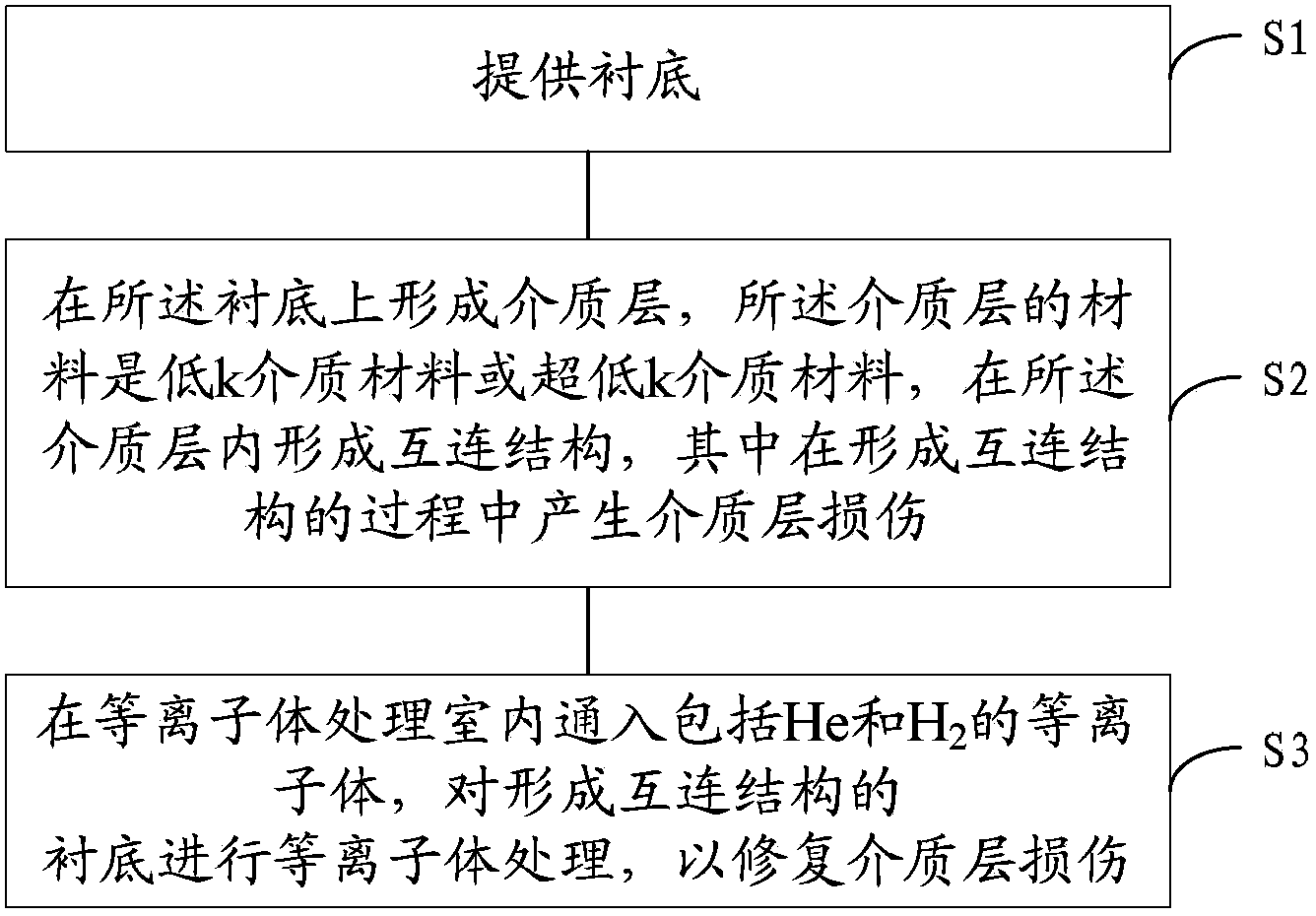

Method for repairing damaged dielectric layer

A technology for repairing dielectrics and dielectric layers, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as increasing RC delay, dielectric layer damage, and increasing k value, and achieve the effect of reducing RC delay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

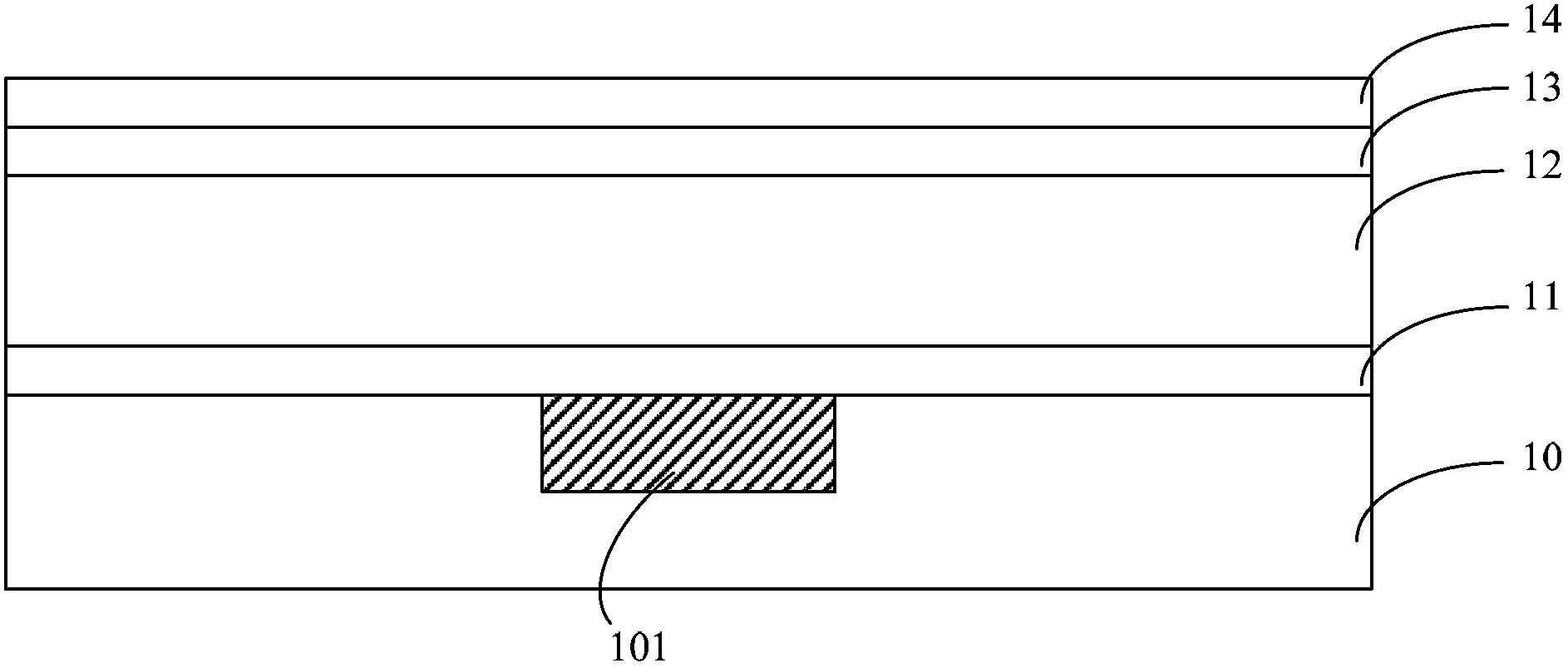

[0038] As mentioned above, the dielectric layer using low / ultra-low-k dielectric materials is vulnerable to plasma and / or chemical agents during semiconductor manufacturing processes such as etching, ashing or planarization due to their porous and soft materials. This will increase the k value of the dielectric layer, thereby increasing the RC delay of the interconnection structure, and it has been found in practice that the lower the k value of the dielectric material, the easier it is to generate low-k damage. The inventors found that using He / H 2 Plasma treatment of the dielectric layer with low-k damage not only does not change the surface properties of the dielectric material, that is, does not change from hydrophobicity to hydrophilicity, but also increases the porosity of the dielectric material and reduces the k value of the dielectric material. Repair the damage of the dielectric layer, thereby reducing the RC delay.

[0039] For this reason, the present invention pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com