Oxygen reduction catalyst and methods for preparing same

一种催化剂、氧化物的技术,应用在催化剂活化/制备、化学仪器和方法、物理/化学过程催化剂等方向,能够解决高性能、达不到Pt系催化剂、催化剂活性和耐久性不足等问题,达到高氧还原性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

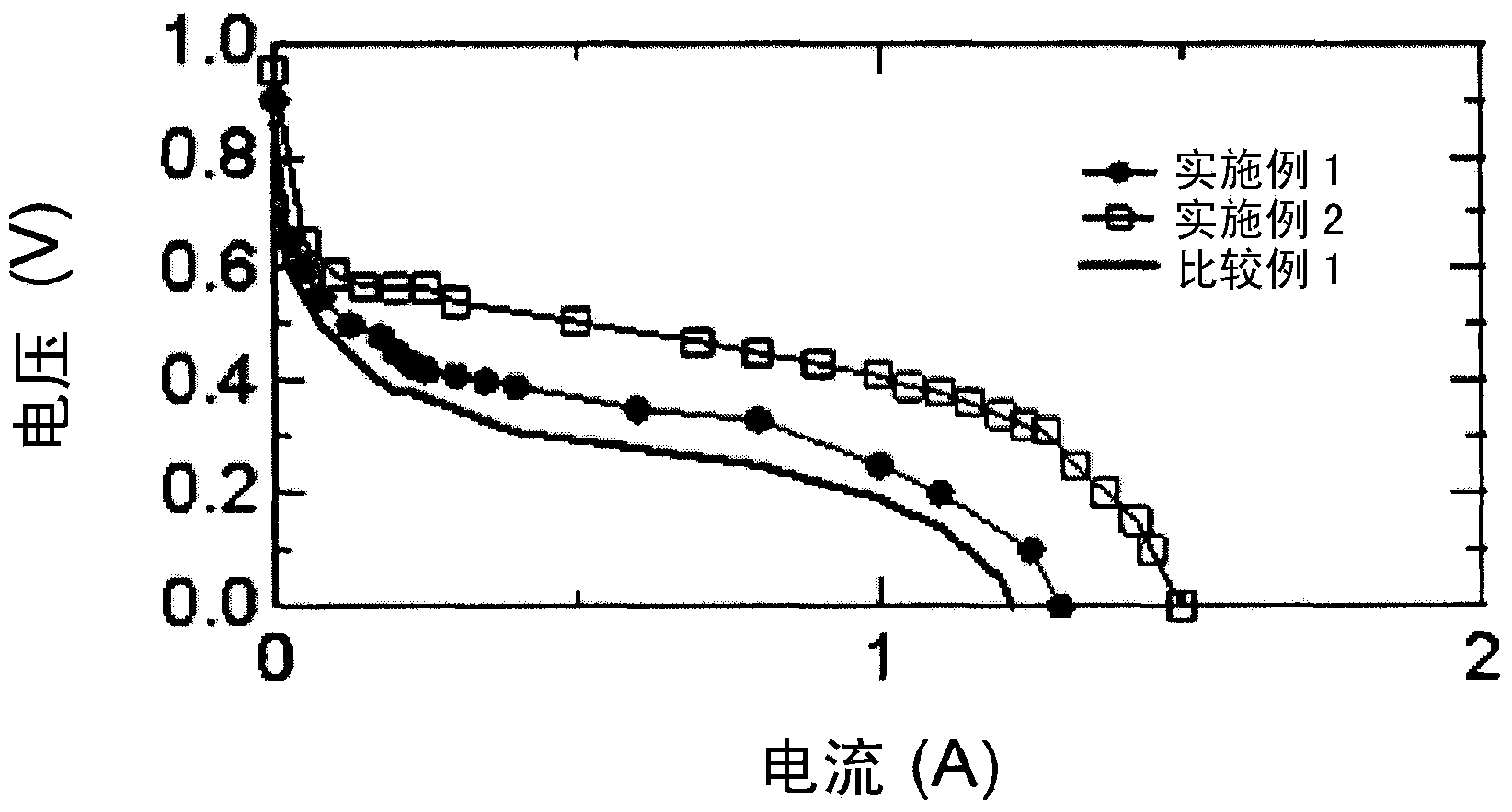

Embodiment 1

[0058] Tantalum carbonitride (TaC) with a particle size of about 1 μm 0.5 N 0.5 ) into a rotary electric furnace (rotary kiln). It was kept at 1000°C for 10 hours in a mixed gas of carbon monoxide gas (diluted to 2% by volume with nitrogen as a carrier gas) and oxygen (diluted to 2% by volume with nitrogen as a carrier gas) to synthesize an oxygen reduction catalyst , which is a mixture of tantalum oxide and carbon.

[0059] Confirmed from powder X-ray diffraction measurements, the formation of 2 o 5 Structured oxide phase. The amount of oxygen vacancies was estimated by elemental analysis with an inert gas fusion infrared absorption method, and was found to be about 4 atomic % (hereinafter, marked as %).

[0060] The cross section of the catalyst was observed by TEM, and it was found that fine carbon having a slightly grown graphitic structure was deposited on its surface. The average primary particle size is 6nm. The carbon coverage of the surface estimated from the T...

Embodiment 2

[0062] A part of the oxygen reduction catalyst synthesized in Example 1 was kept in an ammonia stream at 670° C. for 3 hours to synthesize an oxygen reduction catalyst in which oxygen atoms of tantalum oxide and carbon atoms of carbon were each partially replaced by nitrogen atoms. It was confirmed from powder X-ray diffraction measurements that the b-Ta 2 o 5 Structured oxide phase. Here, the diffraction angles are found to be shifted towards lower angles. Using AlKα monochromatic light, the nuclear level spectrum of Ta4f was observed by X-ray photoelectron spectroscopy, and a shift to the lower energy side was seen, thus confirming that oxygen atoms were partially replaced by nitrogen atoms. Furthermore, in the nuclear level spectrum of C1s, such a peak shift confirming that carbon atoms were partially replaced by nitrogen atoms was observed.

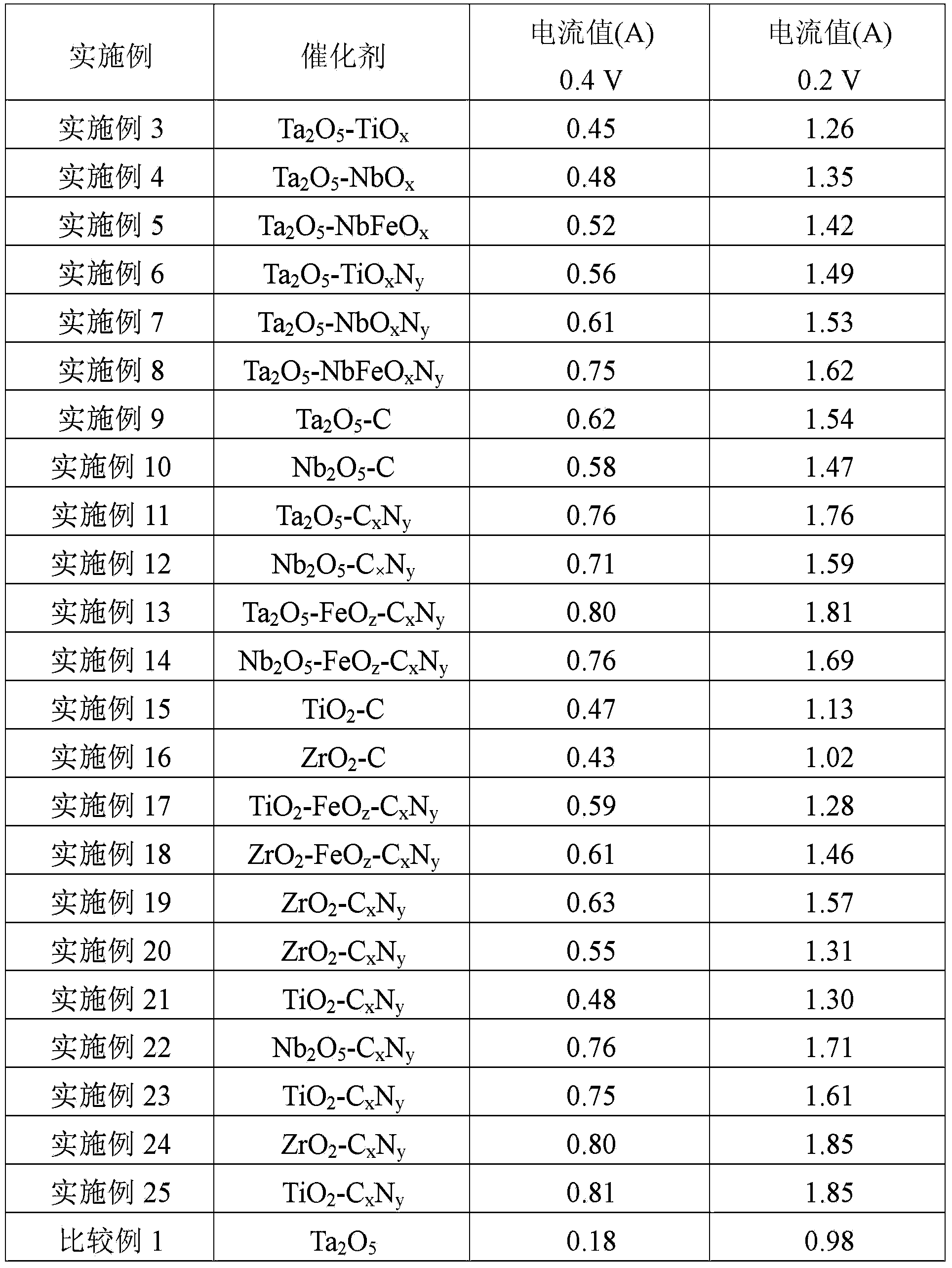

Embodiment 3

[0070] Ti metal was sputtered onto the surface of the oxygen reduction catalyst synthesized in Comparative Example 1, and mixed with hydrogen (diluted to 2 vol% with nitrogen as a carrier gas) and oxygen (diluted to 2 vol% with nitrogen as a carrier gas) ) in a mixed gas at 1000°C for 10 hours. In this way, an oxygen reduction catalyst whose surface is partially covered with TiO x covered with tantalum oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com