A kind of liposome preparation of picantron maleate and its preparation process

A technology of picentan maleate and liposome, which is applied in the directions of liposome delivery, medical preparations of inactive ingredients, antitumor drugs, etc. , difficult to adapt to scale and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1BBR2778

[0051] Embodiment 1BBR2778 liposome

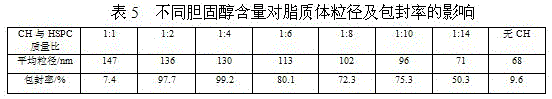

[0052] The composition of liposome membrane material is HSPC:CH:mPEG2000-DSPE=3:1:1 (w / w), and the substance for establishing gradient is citric acid-sodium citrate solution (concentration: 200mM, pH: 4.0).

[0053] In a water bath at 60~65°C, dissolve the membrane materials (ie HSPC, CH and mPEG) with ethanol 2000-DSPE mixture), the ratio of the weight of phospholipids to the volume of ethanol is about 1:2, after waving off part of the ethanol, inject a gradient material solution preheated to the same temperature at a medium speed to establish a substance solution, and incubate for 20min to obtain the initial liposome The product was initially mixed with 200W ultrasonic for 2min, then dispersed with 400W ultrasonic for 4min (working for 1s, intermittent for 1s), and passed through 0.8 and 0.45μm microporous membranes in sequence to obtain a blank liposome suspension. Take some blank liposome suspension, add appropriate amount of Na 3 PO...

Embodiment 2

[0055] The liposome membrane material is DSPC:CH=2:1 (w / w), and the gradient building material solution is malic acid-sodium malate solution (concentration: 100mM, pH: 4.0).

[0056] In a 50°C water bath, dissolve the prescribed amount of membrane material with ethanol. The ratio of the weight of phospholipids to the volume of ethanol is about 1:6. After waving off part of the ethanol, inject a gradient material solution preheated to the same temperature at a medium speed and incubate for 20 minutes. , the primary product of liposome was prepared, after 2 minutes of preliminary mixing treatment with 200W ultrasonic wave, 400W ultrasonic dispersion for 4 minutes (working for 1 s, intermittent for 1 s), passing through 0.8 and 0.45 μm microporous membranes in turn to obtain a blank liposome suspension liquid. Take some blank liposome suspension, add appropriate amount of Na 3 PO 4 Solution (concentration: 500mM) and sterilized water for injection, mix evenly, adjust the pH of ...

Embodiment 3

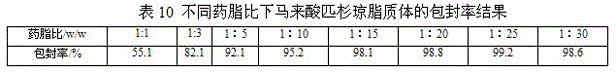

[0058] The liposome membrane material is the same as in "Example 1", and the gradient building materials are selected from tartaric acid-sodium tartrate solution (200mM, pH 4.0) and sodium dihydrogen phosphate solution (200mM, pH 4.0). The preparation process of the liposome primary product is the same as "Example 1". The liposome primary product is treated with micro-jet (12000psi for 2 cycles, 14000psi for 2 cycles), and then through 0.8, 0.45, 0.22, 0.10 , 0.05 μm microporous membrane to obtain a blank liposome suspension. Use Na 3 PO 4 (500mM) to adjust the pH value of the blank liposome suspension to 8.0, and mix the gradient liposome suspension with the BBR2778 solution (concentration: 4.0mg / mL) at a ratio of drug to lipid of 1:15 (w / w), Stir and incubate in a water bath at 60-65°C for 20 minutes, then take it out and place it in an ice-water bath to stop drug loading to obtain BBR2778 liposomes. Use tartaric acid-sodium tartrate solution as gradient to establish the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com