3D printing method of composite parts based on three-cylinder former

A composite material and 3D printing technology, which is applied in the field of composite material parts forming and manufacturing, can solve the problems such as the immaturity of composite material parts forming technology, and achieve the effect of wide application range, lightweight part structure and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

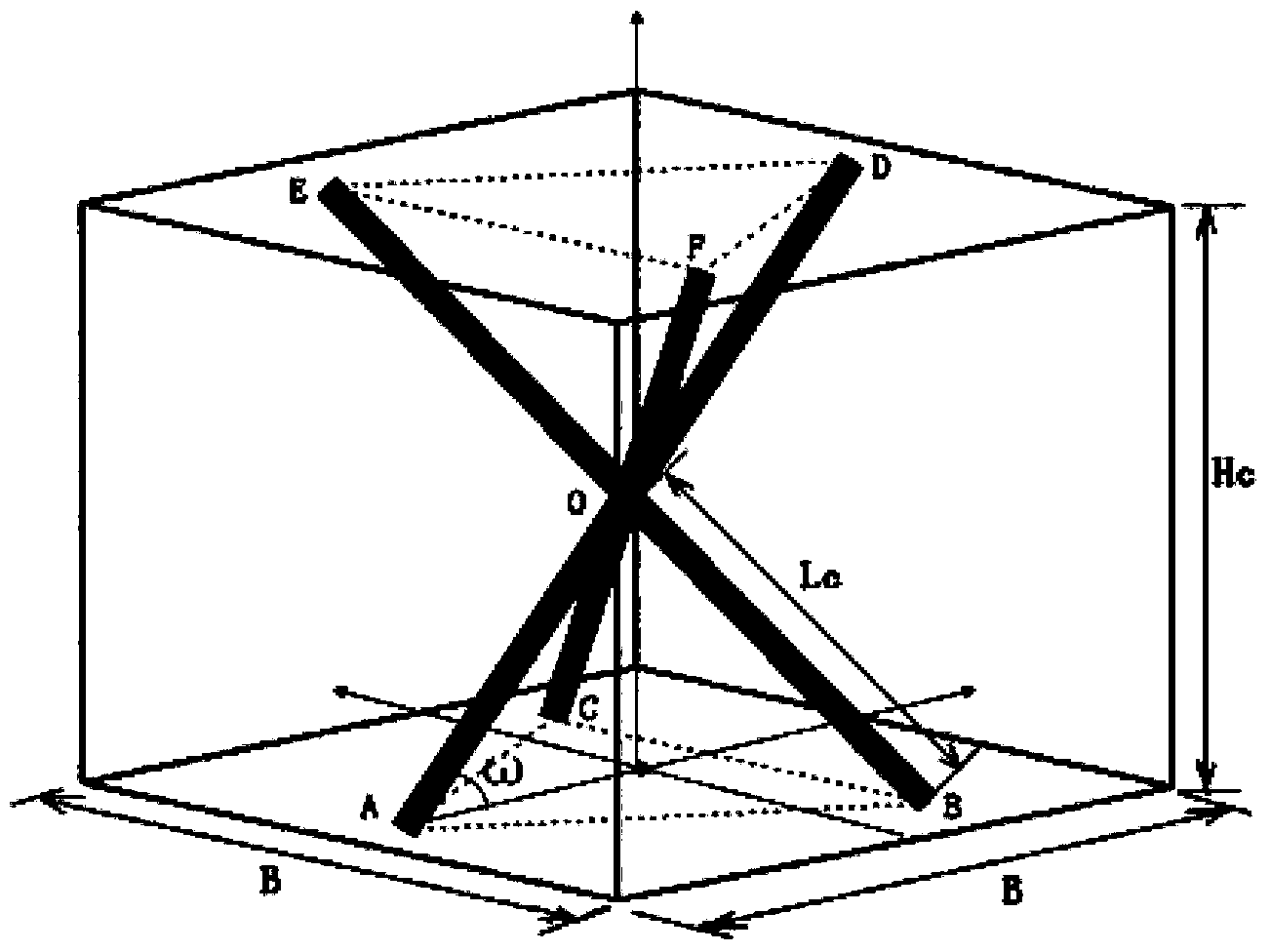

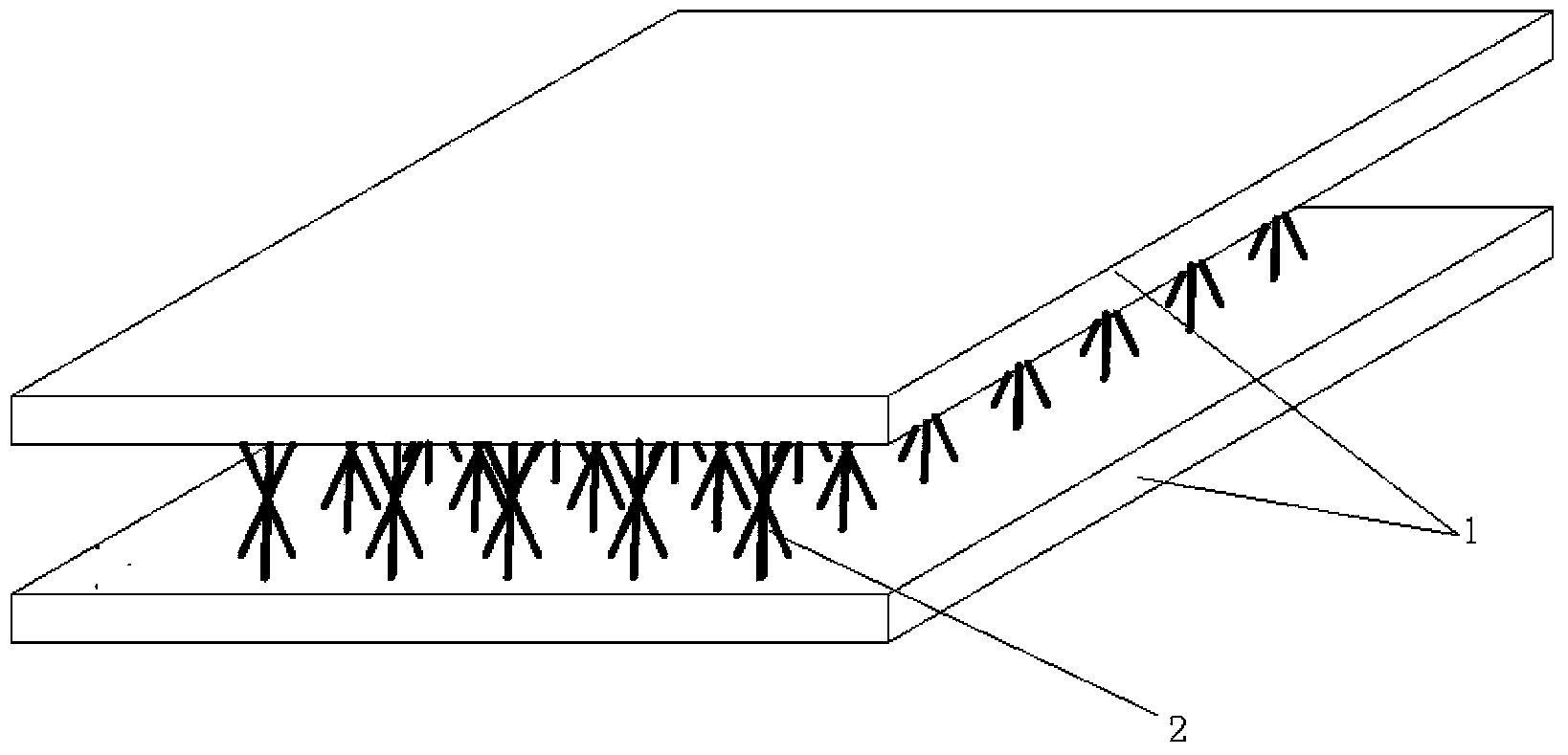

[0024] The present invention is based on the 3D printing method of the composite material part of three-cylinder molding machine, comprises the following steps:

[0025] Use 3D software (SolidWorks, ProE, UG, etc.) to design the part model, or use reverse engineering (CT scanning, 3D scanner, etc.) to reverse the 3D model of the part;

[0026] On the basis of the 3D model, parts of different materials are marked, parts of the same material (or a part of the part) use the same mark, and parts of different materials use different marks;

[0027] Then the 3D model is sliced and layered;

[0028] Prestore the two required powder materials in the powder cylinder of the 3D printer, control the 3D printer system according to the contour information of the 3D model slice, and control two powder feeding cylinders to supply powder to the molding cylinder, and laser (or electron beam) melting and sintering powder, so that one layer of processing is completed;

[0029] Control the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com