3D (three-dimensional) printer powder pre-production device

A 3D printer and powder technology, which is applied in the field of powder spraying components, can solve the problems of immature molding technology of composite material parts, and achieve the effect of simple structure and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

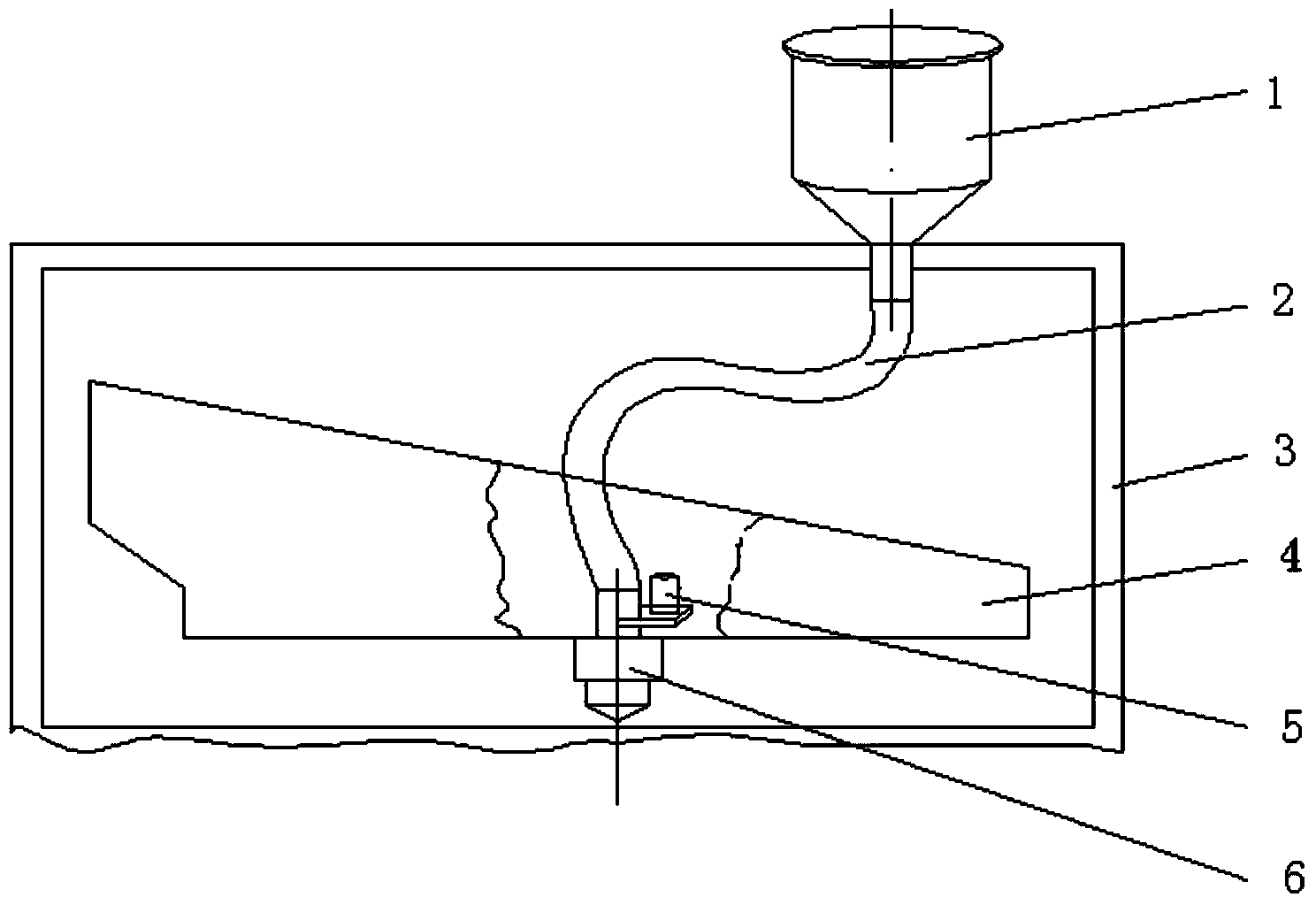

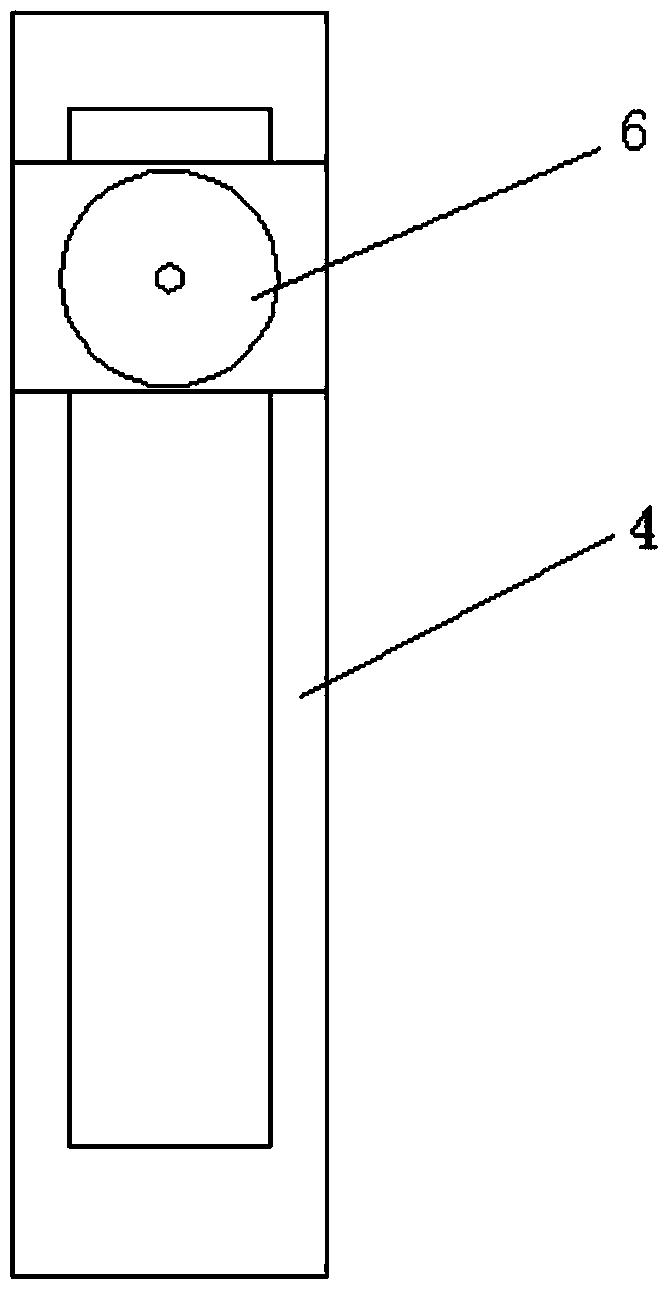

[0021] Such as figure 1 , figure 2 shown. The powder prefabrication device of the 3D printer of the present invention, the powder prefabrication device includes a powder cylinder 1 arranged on the molding chamber 3, a powder arm 4 arranged in the molding chamber 3, and a powder injection head of a disk structure arranged on the powder arm 4 6. The powder spray head 6 is connected to the powder cylinder 1 through the hose 2, and the powder spray head 6 has a valve whose switch is controlled by the motor 5.

[0022] The hose 2 is a circular hose.

[0023] The powder spraying head 6 with the disk structure adopts a precision servo motion system for two-dimensional precision control. The powder spraying head 6 is installed on the powder arm 4, and the circular tube can move in the through groove of the powder arm 4. Through the system of the 3D printer, the powder arm 4 can be controlled to move accurately from side to side, while the powder spraying head 6 can move accuratel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com