Electrolytic etching electroplating accumulation three-dimensional (3D) printer

A 3D printer and print head technology, applied in the field of 3D printing, can solve problems such as low printing efficiency, and achieve the effect of high printing efficiency, high object density, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

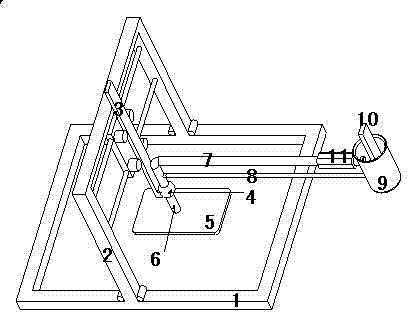

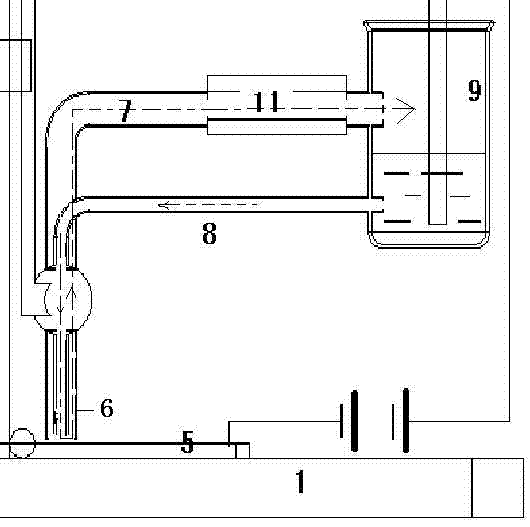

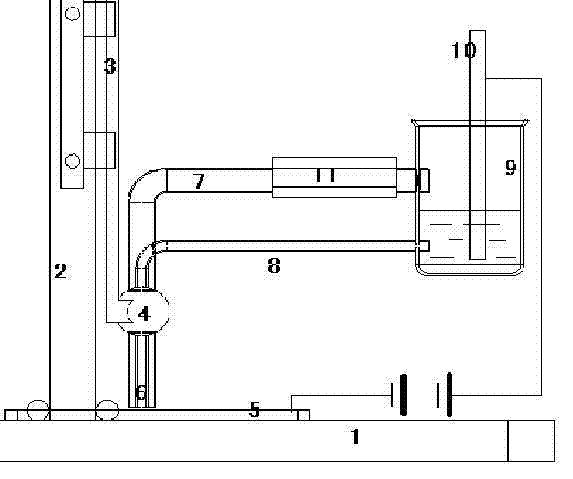

[0021] The present invention will be further described below in conjunction with the accompanying drawings and the embodiment of the printed copper square font mold body.

[0022] Such as figure 1 The shown embodiment is a kind of 3D printer, including shaft track frame (1, 2, 3), universal numerical control bogie (4), metal iron conductive bottom plate (5), installed on the universal numerical control bogie (4) The coaxial sleeve printing head (6) on the top, the return flow outer hose (7) connected with the outer tube of the coaxial sleeve printing head (6), the self-flowing inner hose connected with the inner tube of the coaxial sleeve printing head (6) Hose (8), liquid storage tank (9) filled with copper sulfate solution, metal copper electrode block (10), installed at the end of the return hose (7) to suck back the electrolyte to the numerical control of the liquid storage tank (9) Suction pump (11).

[0023] The metal iron conductive bottom plate (5) is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com