Synthesis of hyperbranched azo polymer and modification method of same

A kind of technology of azo polymer and synthesis method, which is applied in the direction of chemical instruments and methods, optical record carriers, color-changing fluorescent materials, etc., to achieve the effect of cheap raw materials, easy availability of raw materials, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

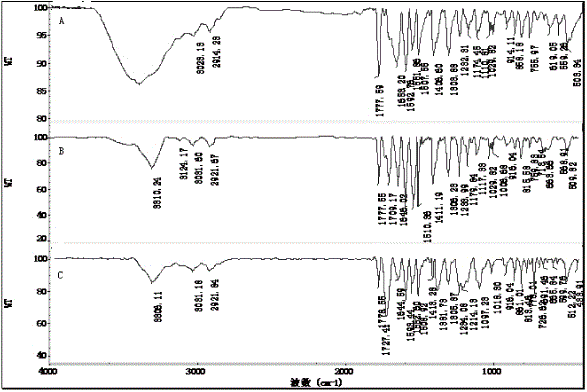

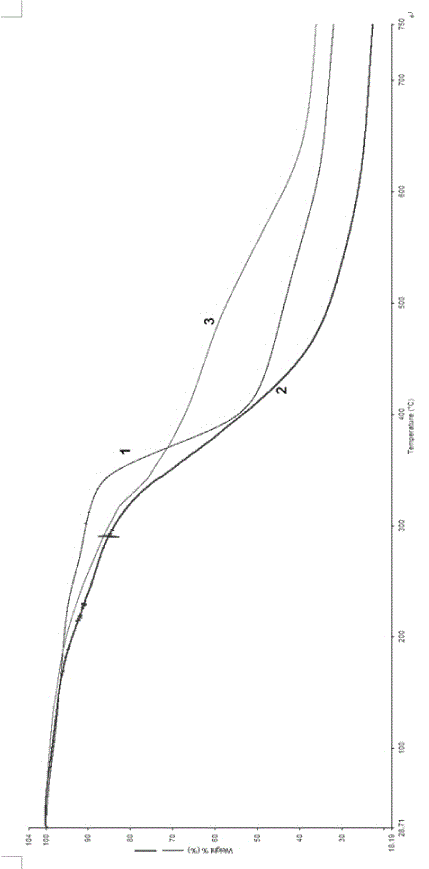

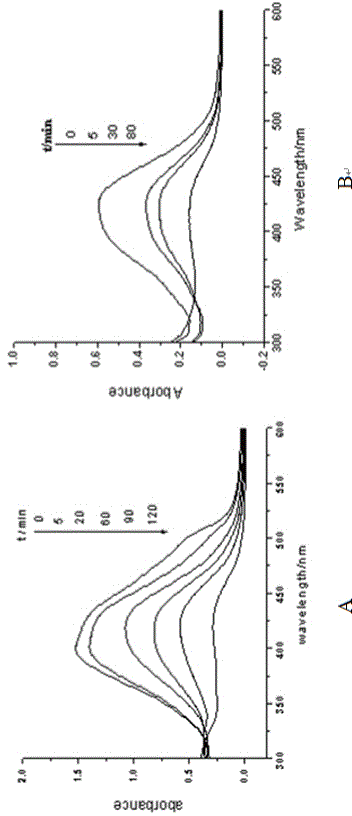

Image

Examples

Embodiment 1

[0030] Raw materials and ratio:

[0031] Azoresorcinolsulfonic acid 5.0g

[0032] 4,4’-Diphenylmethane diisocyanate 5.9 g

[0033] N,N-Dimethylformamide 207.0 g

[0034] Preparation Process:

[0035] Firstly, azoresorcinolsulfonic acid was dissolved in DMF to form a solution with a concentration of 5 ± 0.25% by mass, which was set aside. In pass N 2 Under certain conditions, add 4,4'-diphenylmethane diisocyanate (MDI) and DMF into a four-neck flask, stir and dissolve at 35±5°C to form a solution with a mass percentage concentration of 5±0.25%, and 35±5°C Next, add azoresorcinolsulfonic acid DMF solution dropwise over 4 to 5 hours. After the dropwise addition, at 35±5° C., a constant temperature reaction was carried out for 248 hours, and the synthesis reaction was completed.

Embodiment 2

[0037] Raw materials and ratio:

[0038] Azoresorcinolsulfonic acid 3.0g

[0039] 4,4’-Diphenylmethane diisocyanate 2.4 g

[0040] N,N-Dimethylformamide 103.0 g

[0041] Preparation Process:

[0042] Firstly, azoresorcinolsulfonic acid was dissolved in DMF to form a solution with a concentration of 5 ± 0.25% by mass, which was set aside. In pass N 2 Under certain conditions, add 4,4'-diphenylmethane diisocyanate (MDI) and DMF into a four-neck flask, stir and dissolve at 35±5°C to form a solution with a mass percentage concentration of 5±0.25%, and 35±5°C Next, add azoresorcinolsulfonic acid DMF solution dropwise over 4 to 5 hours. After the dropwise addition, at 35±5° C., a constant temperature reaction was carried out for 248 hours, and the synthesis reaction was completed.

Embodiment 3

[0044] Raw materials and ratio:

[0045] Azoresorcinolsulfonic acid 50.0 g

[0046] 4,4’-Diphenylmethane diisocyanate 59.0 g

[0047] N,N-Dimethylformamide 2071.0 g

[0048] Preparation Process:

[0049] Firstly, azoresorcinolsulfonic acid was dissolved in DMF to form a solution with a concentration of 5 ± 0.25% by mass, which was set aside. In pass N 2 Under certain conditions, add 4,4'-diphenylmethane diisocyanate (MDI) and DMF into a four-neck flask, stir and dissolve at 35±5°C to form a solution with a mass percentage concentration of 5±0.25%, and 35±5°C Next, add azoresorcinolsulfonic acid DMF solution dropwise over 4 to 5 hours. After the dropwise addition, at 35±5° C., a constant temperature reaction was carried out for 248 hours, and the synthesis reaction was completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com