Adjustment and design method for lighting system matching multiple objective lens in extreme ultraviolet lithography machine

An extreme ultraviolet lithography and lighting system technology, applied in the field of lithography lighting design, can solve the problems of increasing manufacturing costs, consuming a lot of manpower and material resources, etc., and achieve the effects of reducing design and manufacturing costs, reducing design costs, and shortening the research and development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

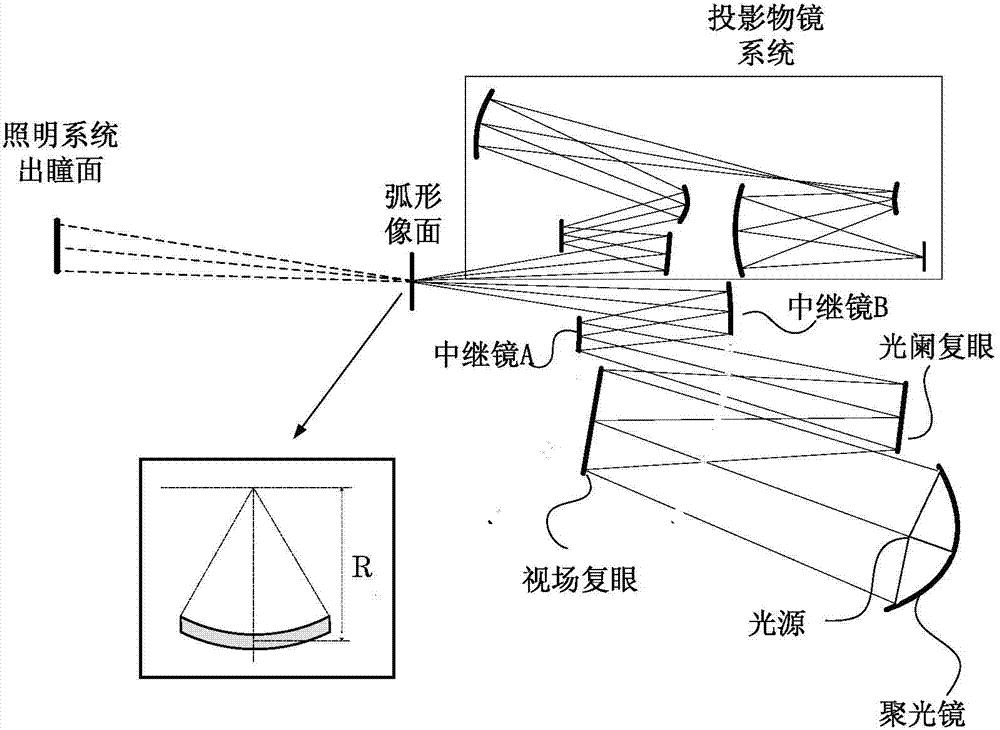

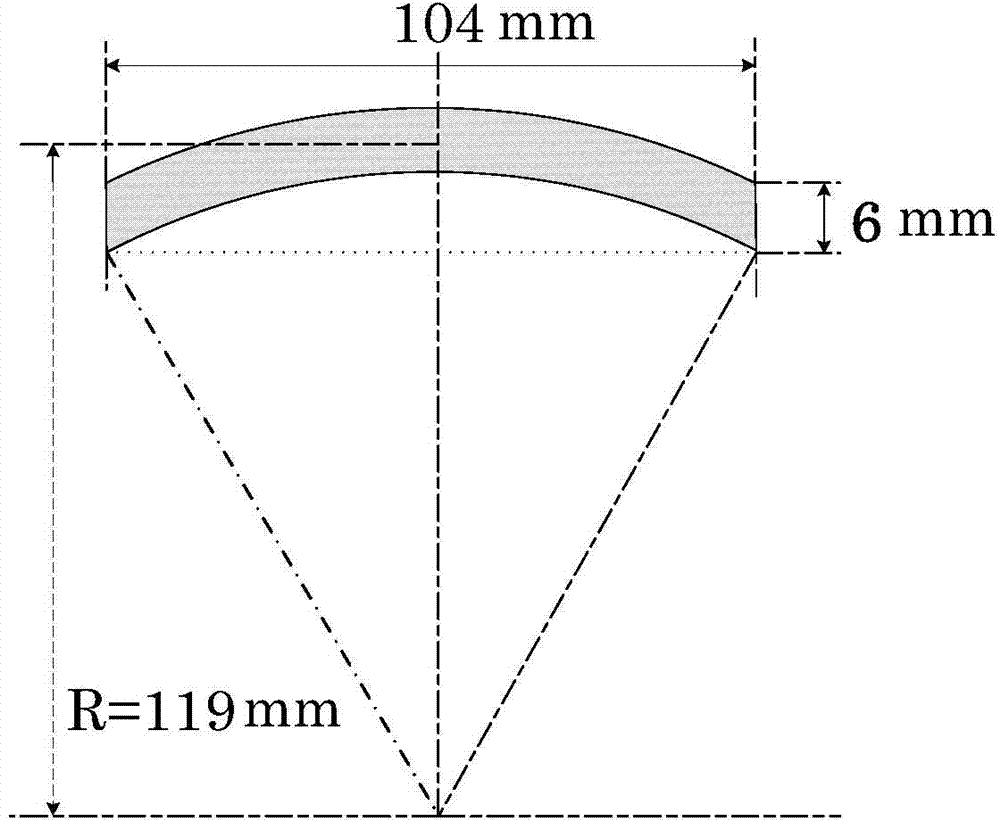

[0045] Table 1 shows three sets of design indexes of lighting systems matched with different projection objectives, wherein the first set is used as the design indexes of the initial lighting system, and the other two sets are obtained according to the design of the present invention. The three systems all use laser plasma light source, and the parameters of the light source condenser are calculated based on the data provided by EUV light source manufacturer Cymer. Its structure is as follows: Figure 4 shown. The size of the curved object plane in all objective lens systems is the same, and its structure is as follows image 3 As shown, but the incident angle of the chief ray and the numerical aperture of the object side are different in each set of the curved object surface, so the entrance pupil parameters are also different. Since the incident angle of the chief ray on the curved object surface in the extreme ultraviolet lithography objective lens system usually varies be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com