Device and method for electric machining with circular electrode and ultrasonic wave used for cutting

A circular electrode and electric processing technology, which is applied in the field of cutting equipment, can solve problems such as inability to process, and achieve the effects of improving processing efficiency, uniform width, and ensuring dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

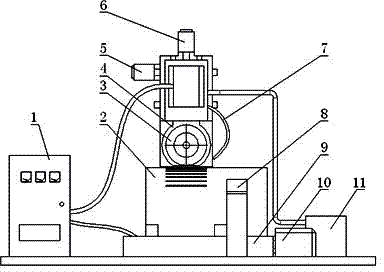

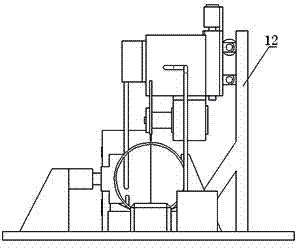

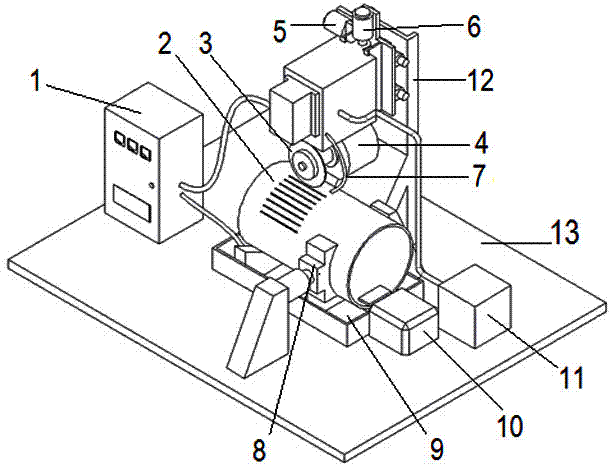

[0025] combined with Figure 1-3 , to further describe the present invention:

[0026] An electrical processing equipment for cutting with circular electrodes and ultrasonic waves, including a power supply and servo control unit 1, a workpiece 2, a circular electrode 3, a DC motor 4, a longitudinal feed device 5, a vertical feed device 6, and a working fluid spray Device 7, workpiece pneumatic clamping device 8, working fluid recovery tank 9, ultrasonic vibration device 10, working fluid purification and circulation device 11, column 12 and base 13, power supply and servo control unit 1, working fluid recovery tank 9 are installed on the base 13 , an ultrasonic vibrating device 10, a working fluid purification and circulation device 11, a column 12, the upper part of the working fluid recovery tank 9 fixes the workpiece 2 through the workpiece pneumatic clamping device 8 and the column 12, and a DC motor 4 is installed in the middle of the column 12, The outer end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com