A treatment process for methanol synthesis purge gas recovery and partial production of hydrogen products

A methanol synthesis and treatment process technology, applied in the field of coal chemical industry, can solve the problems of increased investment and quantity of membrane separation systems, and achieve the effects of reasonable process technology, small device scale, and small desorbing gas compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments, but the present invention is not limited.

[0027] In order to make the technical means, creative features and effects of the present invention easy to understand, the content of the present invention will be further explained through application examples and the accompanying drawings.

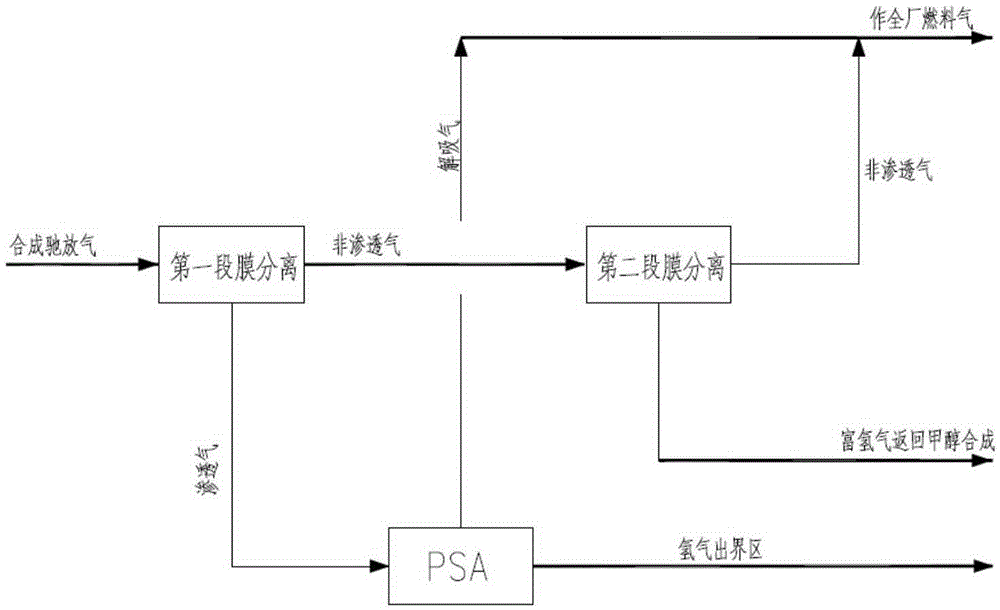

[0028] The following example takes a coal-to-olefin synthesis engineering plastics project as an example. The scale of the methanol plant is about 1.5 million tons / year of methanol, and methanol synthesis purge gas (6.52MPaG, H 2 ~68.2%) The amount is about 24700Nm 3 / h, the amount of hydrogen required downstream is 3100Nm 3 / h (pressure 4.0MPaG, H2~99.9%).

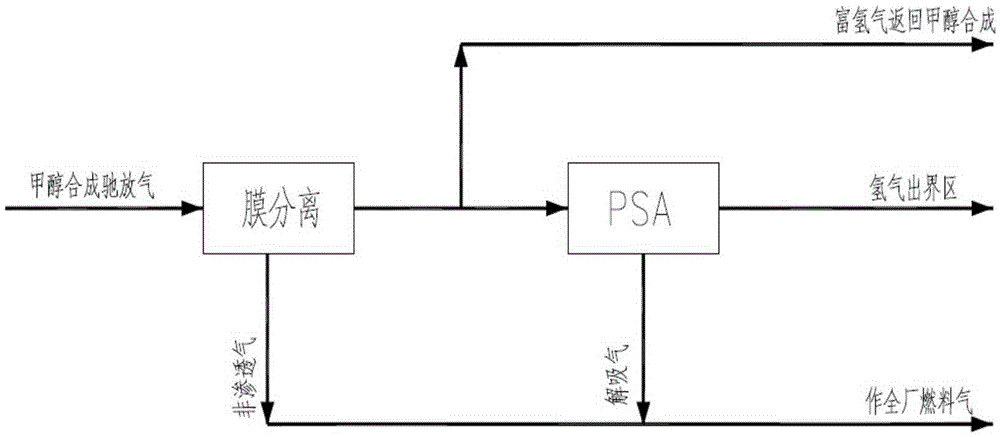

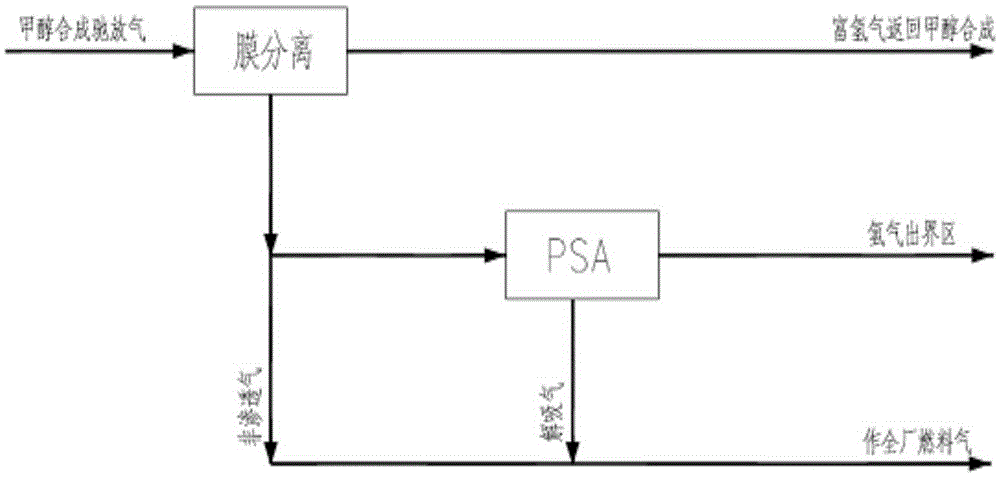

[0029] The process flow is described as follows:

[0030] The methanol synthesis purge gas first enters the first stage of membrane separation to produce 3690Nm 3 / h (4.4MPaG, H 2 ~91.3%) permeate gas, sent to PSA device, the remaining non-permea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com