Method for producing industrial excellent ammonium sulfate through coarse ammonium sulfate coking coupling evaporation solventing-out crystallization

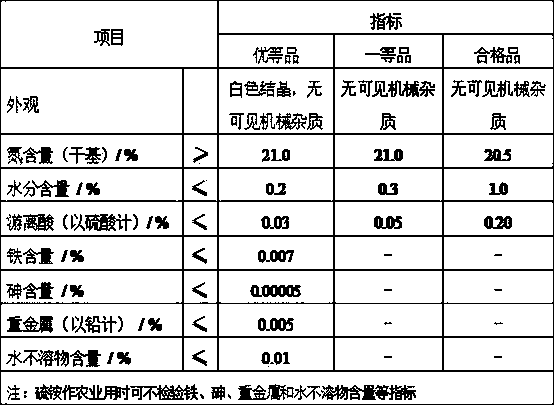

A technology for elution crystallization and production industry, applied in the field of ammonium sulfate, can solve the problems of easy crystal sinking, high solubility, prolonged crystallization time, etc., and achieve the effects of slowing down the growth rate, reducing the impurity content, and improving the color grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Coking crude ammonium sulfate is coupled with evaporation, dissolution and crystallization to produce the method for industrial superior product ammonium sulfate, and its specific steps are:

[0037] Step 1. Under the conditions of normal pressure, 40~60°C and 300~400r / min rotation speed, first prepare a coking crude ammonium sulfate aqueous solution with a concentration of 40~45wt%; then use NaOH to adjust the pH of the coking crude ammonium sulfate solution to 7~ 8; then adding activated carbon accounting for 1-3wt% of the coking crude ammonium sulfate to the coking crude ammonium sulfate aqueous solution, insulated and stirred for 0.5-1h and then insulated and filtered to obtain the coking crude ammonium sulfate crystallization mother liquor;

[0038] Step 2. Under normal pressure, 40~60°C and 300~400r / min rotating speed conditions, first add an acid regulator to the coking crude ammonium sulfate crystallization mother liquor prepared in step 1 to make the mother liqu...

Embodiment 2

[0043] Coking crude ammonium sulfate is coupled with evaporation, dissolution and crystallization to produce the method for industrial superior product ammonium sulfate, and its specific steps are:

[0044] Step 1. Under the conditions of normal pressure, 60~80°C and 350~450r / min, first prepare a coking crude ammonium sulfate aqueous solution with a concentration of 43~48wt%; then use NaOH to adjust the pH of the coking crude ammonium sulfate solution to 8~ 9; Then, add activated carbon accounting for 2-4wt% of the coking crude ammonium sulfate to the coking crude ammonium sulfate aqueous solution, heat-preserve and stir for 0.5-1h and then insulate and filter to obtain the coking crude ammonium sulfate crystallization mother liquor;

[0045] Step 2. Under normal pressure, 60-80°C and a rotating speed of 350-450r / min, first add an acid regulator to the coking crude ammonium sulfate crystallization mother liquor prepared in step 1 to make the mother liquor pH=6~7; Add a crystal...

Embodiment 3

[0050] Coking crude ammonium sulfate is coupled with evaporation, dissolution and crystallization to produce the method for industrial superior product ammonium sulfate, and its specific steps are:

[0051] Step 1. Under the conditions of normal pressure, 80~100°C and 400~500r / min, first prepare a coking crude ammonium sulfate aqueous solution with a concentration of 45~50wt%, and then use NaOH to adjust the pH of the coking crude ammonium sulfate solution to 7~ 9; then add activated carbon accounting for 3-5wt% of the coking crude ammonium sulfate to the coking crude ammonium sulfate aqueous solution, insulate and stir for 0.5-1h and then insulate and filter to obtain the coking crude ammonium sulfate crystallization mother liquor;

[0052] Step 2. Under normal pressure, 80-100°C and 400-500r / min rotating speed conditions, first add an acid regulator to the coking crude ammonium sulfate crystallization mother liquor prepared in step 1 to make the mother liquor pH=5~7; Add a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com