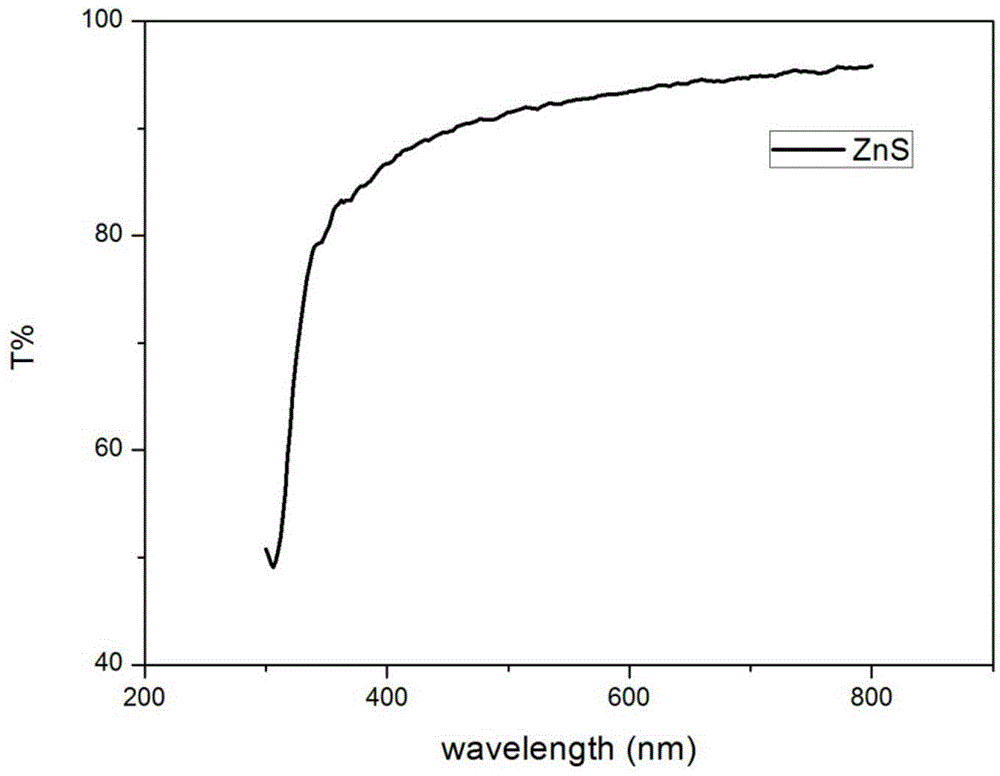

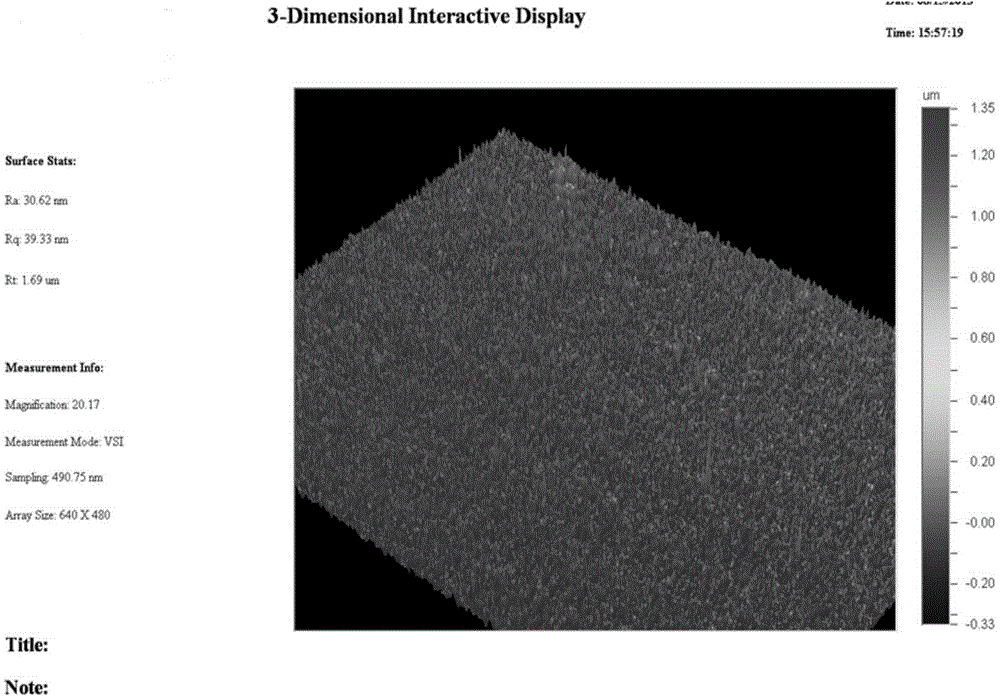

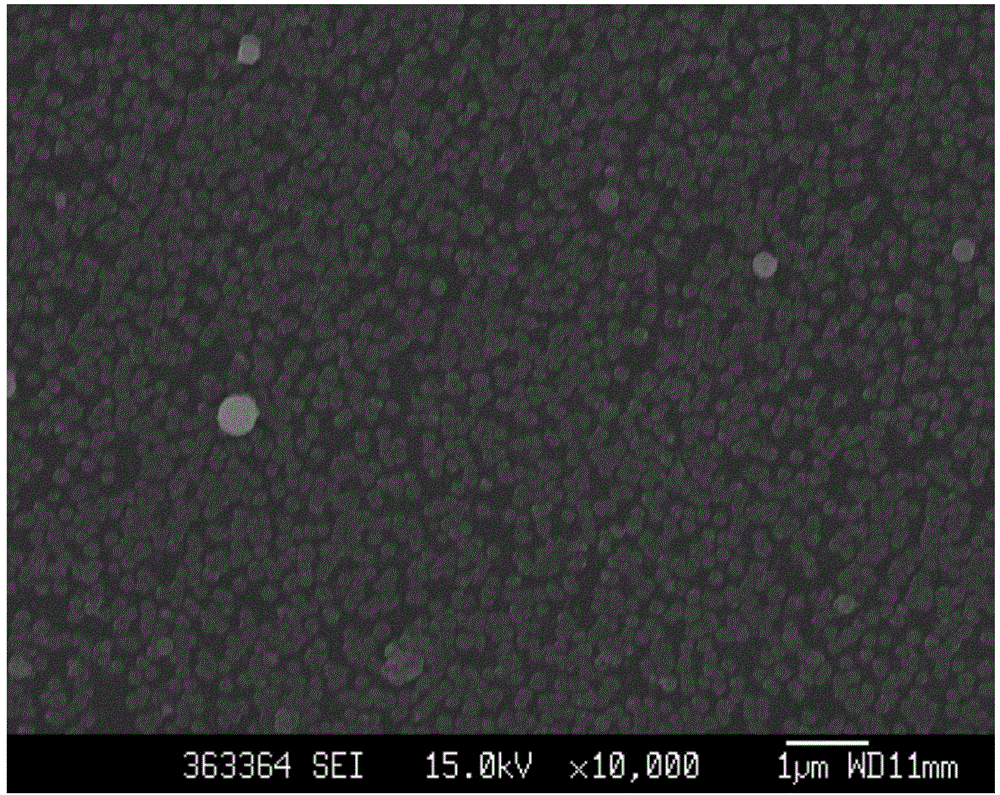

ZnS nano-crystalline film and preparation method and application thereof

A nanocrystal and thin film technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of restricted use, human and environmental hazards, and difficulty in ZnS film formation and preparation efficiency. The effect of improving short-circuit current, cheap price and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] ZnS nanocrystalline film is prepared according to the following steps:

[0032] (1) Preparation of the substrate: first clean the substrate, ultrasonically clean it for 15 minutes in the order of acetone, absolute ethanol, and deionized water, and then dry it for storage.

[0033] (2) Prepare 200ml of basic solution, the concentration of ZnSO4 in the prepared basic solution is 0.05mol / L, and the concentration of (NH4)2SO4 is 0.01mol / L.

[0034] (3) Put the basic solution in a water bath environment and heat it in a water bath. When it is heated to 80°C, add ammonia solution and SC(NH2)2 solution to it at the same time to obtain a mixed solution, and make ammonia water and SC(NH2)2 in the mixed solution The concentrations in are 1.5mol / L and 0.3mol / L respectively;

[0035] (4) Put the substrate in step 1 vertically into the mixed solution, then slowly add triethanolamine dropwise, and the concentration of the added triethanolamine in the mixed solution is controlled to ...

Embodiment 2

[0039] ZnS nanocrystalline film is prepared according to the following steps:

[0040] (1) Preparation of the substrate: first clean the substrate, ultrasonically clean it for 15 minutes in the order of acetone, absolute ethanol, and deionized water, and then dry it for storage.

[0041] (2) Prepare 200ml of basic solution, the concentration of ZnSO4 in the prepared basic solution is 0.2mol / L, and the concentration of (NH4)2SO4 is 0.1mol / L.

[0042] (3) Put the basic solution in a water bath environment and heat it in a water bath. When it is heated to 80°C, add ammonia solution and SC(NH2)2 solution to it at the same time to obtain a mixed solution, and make ammonia water and SC(NH2)2 in the mixed solution The concentrations in are 3.0mol / L and 0.5mol / L respectively;

[0043](4) Put the substrate in step 1 vertically into the mixed solution, then slowly add triethanolamine dropwise, and the concentration of the added triethanolamine in the mixed solution is controlled to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com