Method of preparing high-purity tanshinone IIA sodium sulfonate

A technology of tanshinone and sodium sulfonate, applied in steroids, organic chemistry and other directions, can solve the problems of poor tanshinone IIA product purity, low yield of tanshinone IIA sodium sulfonate, and increased patient risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

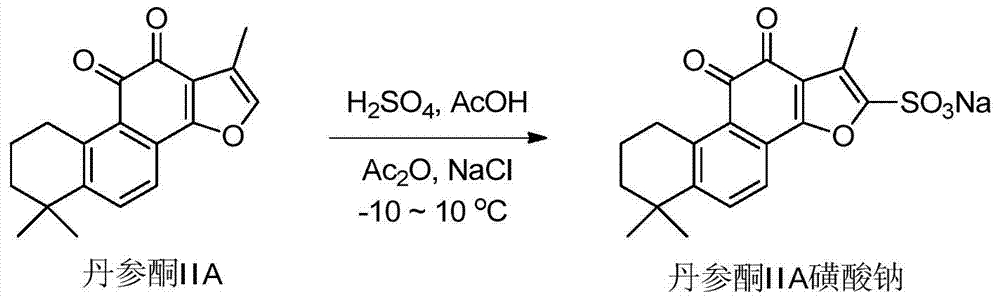

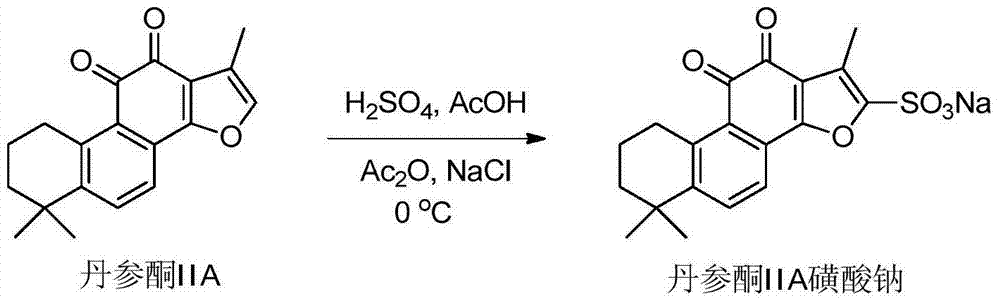

Method used

Image

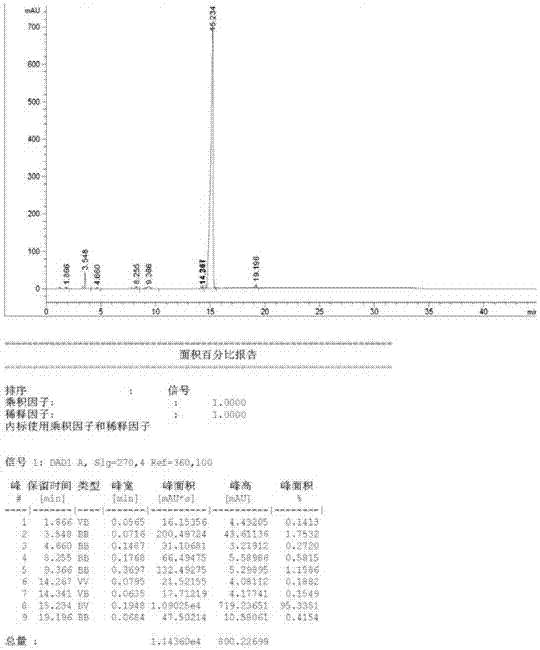

Examples

Embodiment 1

[0018]

[0019] Add 80 grams of commercially available tanshinone extract (about 60% of tanshinone IIA content) to 140 ml of glacial acetic acid, then add 240 ml of acetic anhydride, and stir and cool the resulting mixture in an ice-water bath. Add 120 ml of a mixture of concentrated sulfuric acid / glacial acetic acid (1 / 1) dropwise to the reaction solution, and keep the temperature of the reaction solution below 5°C during the dropwise addition. After the dropwise addition was completed, stirring was continued for 1.5 hours until the reaction was complete. In an ice-water bath, the reaction solution was slowly poured into an equal volume of distilled water, and 1.2 liters of saturated sodium chloride aqueous solution was added immediately, and solids were precipitated. The solid suspension obtained above is centrifuged, and the precipitate is washed twice with saturated sodium chloride solution, and then washed once with an appropriate amount of water, so that the pH of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com