Microbiological solid-state seed producing and fermenting device

A fermentation device and microorganism technology, applied in the field of microbial reaction devices, can solve the problems of difficulty in production, low degree of automation, low production efficiency, etc., and achieve the effects of reducing the infection rate of miscellaneous bacteria, high degree of automation, and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

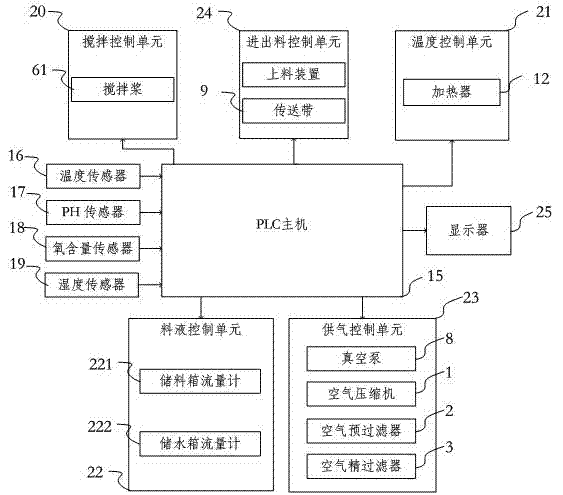

[0033] refer to Figure 1~4 , using solid strains for microbial solid-state seed production and fermentation, specifically including the following steps:

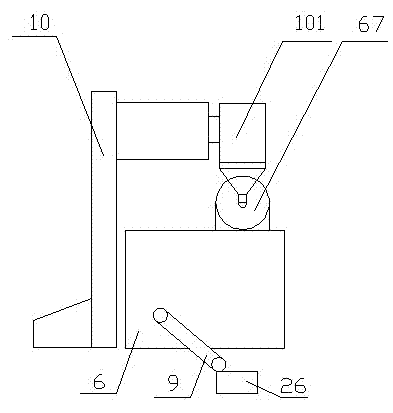

[0034] 1) Steaming and sterilizing: automatically add solid culture into the feed port 67 of the fermenter 6 through the feeding device

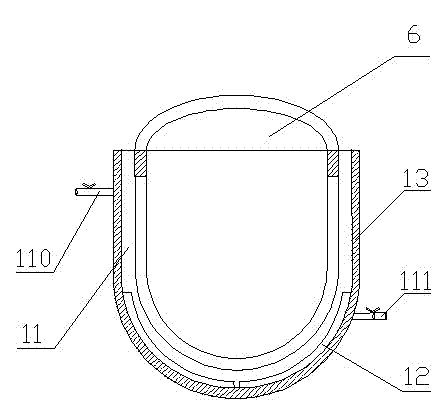

[0035]Base, after opening the vacuum pump 8 to keep the vacuum state in the fermenter 6, close the vacuum pump 8, and feed steam into the jacket 11 to carry out high-temperature sterilization;

[0036] 2) Inoculation: Into the fermenter 6, pass through the sterile compressed air obtained by the fine air filter 3 for sterilization, cool the solid culture to the temperature required for inoculation, insert the solid bacteria, start the stirring device, and fermenter 6 The internal solid medium is fully mixed and then fermented;

[0037] 3) Strain culture: set the temperature, humidity, ventilation and stirring speed required for the culture of the strain, open

[0038] Heater 12 enters t...

Embodiment 2

[0046] refer to Figure 1~4 , using liquid strains for microbial solid-state seed production and fermentation, the difference from Example 1 is that in step 2), when the solid medium in the fermenter 6 reaches a temperature that can be inoculated, the liquid strains are inserted, and the The liquid strain is sprayed onto the solid culture medium through the nozzle from the feeding liquid inlet 62, the stirring device is turned on, and the strain culture is carried out after being fully mixed with the solid culture medium in the fermenter 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com