Production method of powder containing 2-o-α-d-glucosyl-l-ascorbic acid anhydrous crystals

An ascorbic acid and glucose-based technology is applied in the field of manufacturing powder containing 2-O-α-D-glucosyl-L-ascorbic acid anhydrous crystals, and can solve the problems of poor universality of the manufacturing method and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0091] 1. Definition of terms

[0092] In this specification, the following terms have the following meanings.

[0093]

[0094] The "degree of crystallinity of ascorbic acid 2-glucoside anhydrous crystals" as used in this specification means a numerical value defined by the following formula [1].

[0095] Formula 1]:

[0096] 【Number 1】

[0097]

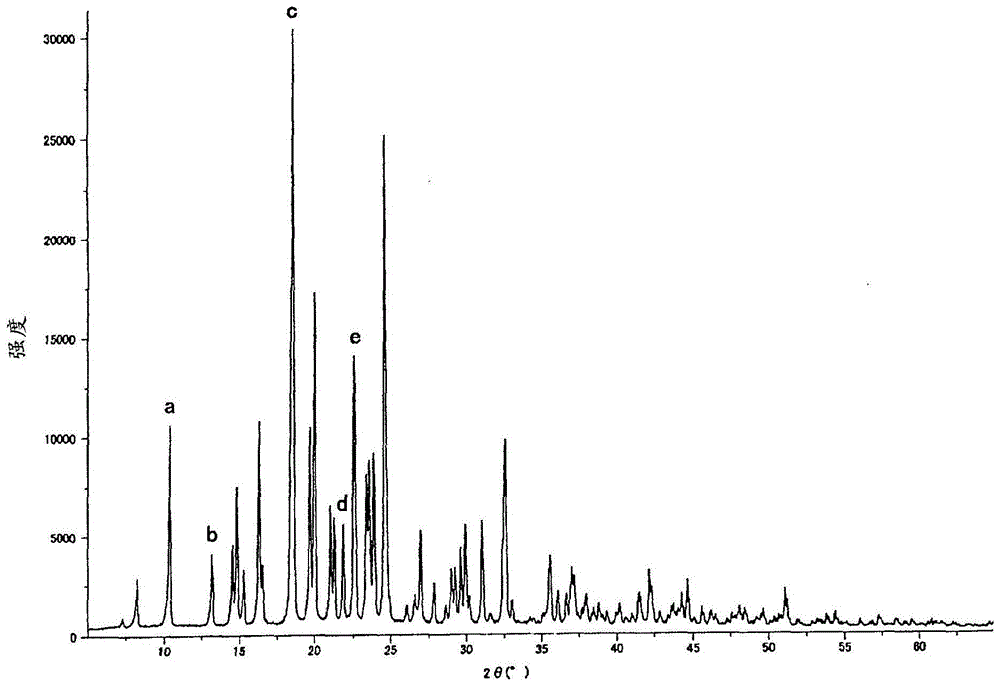

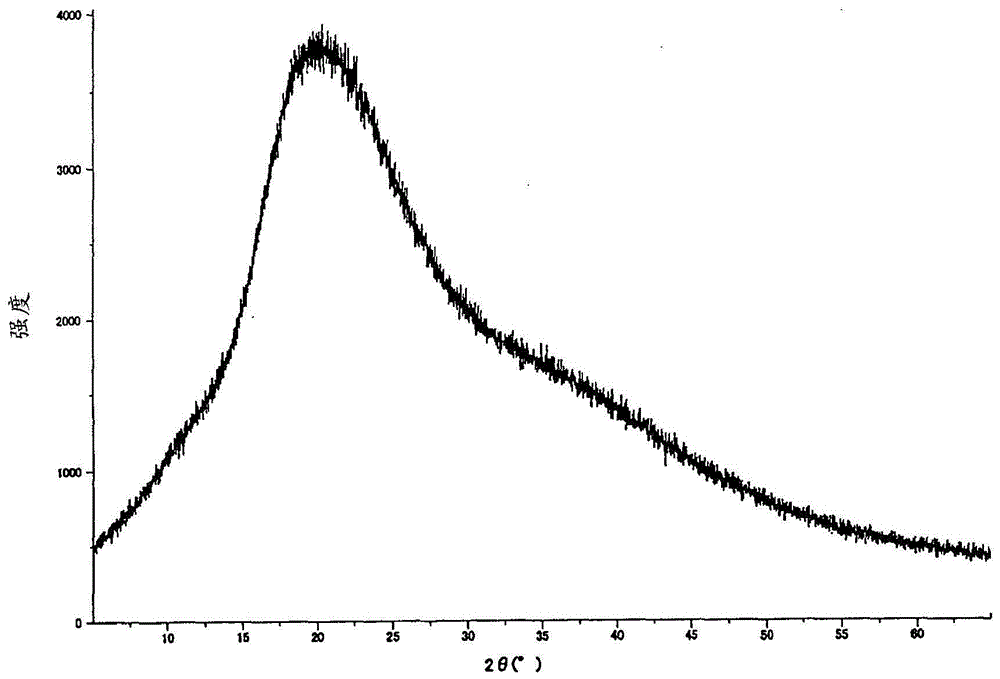

[0098] h 100 : Analytical value of the degree of crystallinity obtained from powder X-ray diffraction characteristics of a powder standard sample containing ascorbic acid 2-glucoside anhydrous crystals substantially composed of ascorbic acid 2-glucoside anhydrous crystals

[0099] h 0 : Analytical value of the degree of crystallinity obtained from powder X-ray diffraction characteristics of a powder standard sample containing ascorbic acid 2-glucoside, which is basically composed of an amorphous part

[0100] h s : The analytical value of the degree of crystallinity obtained from the powder X-ray diffraction characteristi...

Embodiment 1

[0415]

[0416] 4 mass parts of liquefied potato starches were heated and dissolved by adding 20 mass parts of water, and 3 mass parts of L-ascorbic acid were added to adjust the pH to 5.5 to obtain a substrate solution. To this, 100 units of CGT derived from Geobacillus stearothermophilus Tc-91 strain (Accession No. FERMBP-11273 of the Patent Organism Deposit Center of the National Institute of Advanced Industrial Science and Technology) was added per 1 g of solid content of liquefied potato starch Enzyme crude enzyme solution (manufactured by Hayashibara Biochemical Research Institute Co., Ltd.), react at 55°C for 40 hours, together with ascorbic acid 2-glucoside, generate 2-O-α-maltosyl-L-ascorbic acid, 2-O-α α-glycosyl-L-ascorbic acid such as maltotriosyl-L-ascorbic acid and 2-O-α-maltotetraosyl-L-ascorbic acid.

[0417] After heating the reaction solution to inactivate the enzyme, adjust the pH to 4.5, add 50 units of glucoamylase agent (marketed by Amano Enzyme Co., Lt...

Embodiment 2

[0423]

[0424] When making CGTase act on a solution containing liquefied starch and L-ascorbic acid, pullulanase (marketed by Hayashibara Biochemical Research Institute Co., Ltd., product code (EN201), Pneumonia K Klebsiella pneumoniae (Aerobacter aerogenes) source, and when crystallizing ascorbic acid 2-glucoside anhydrous crystallization, it is suitable to cool the temperature of the solution from 40°C to 35°C over 1.5 days Thereafter, except for the quasi-controlled cooling method of cooling from 35° C. to 15° C. in 0.5 days, a powder containing ascorbic acid 2-glucoside anhydrous crystals was produced in the same manner as in Example 1. In addition, the reaction liquid after glucoamylase treatment The production rate of ascorbic acid 2-glucoside in is about 29.5%.The ascorbic acid 2-glucoside content of the solution used for the crystallization of ascorbic acid 2-glucoside anhydrous crystals is 91.8% in anhydrous conversion.

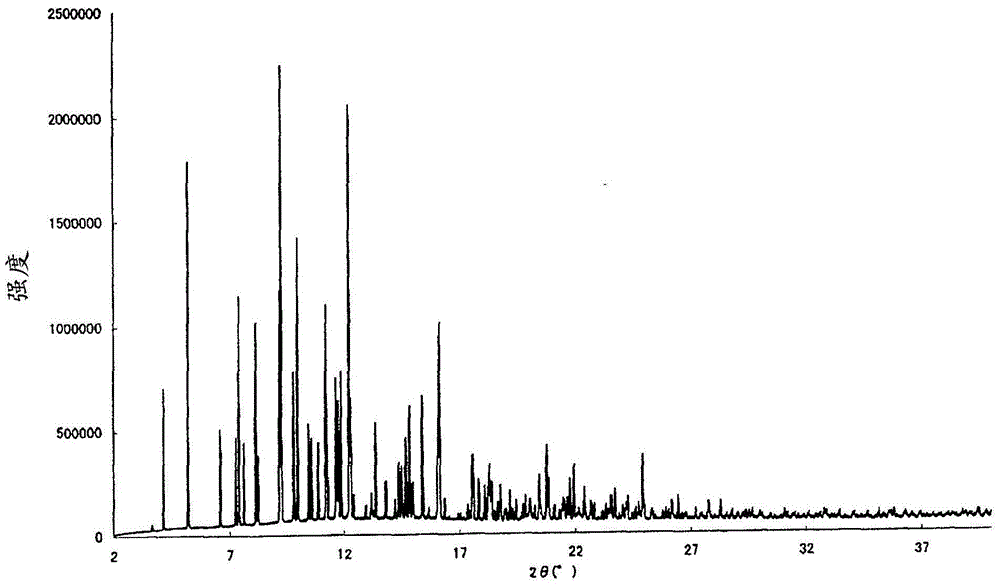

[0425] This product has a purity of 99.5% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com