Method for extracting albumen powder from corn germ meal

A technology of corn germ meal and protein powder, which is applied in the field of protein engineering, can solve the problems of narrow application range and achieve the effects of wide application range, low energy consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

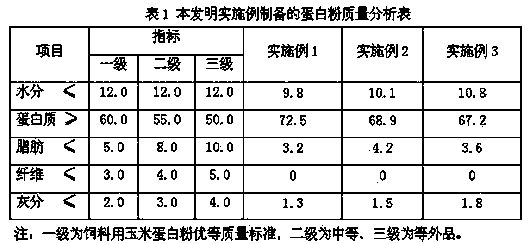

Examples

Embodiment 1

[0035] A method for extracting protein powder from corn germ meal includes the following steps:

[0036] (1) After steaming, frying, squeezing and extracting corn oil, 5 kg of corn germ meal is crushed and passed through a 200-mesh sieve. 95kg of water is added. The weight ratio of water to corn germ meal is 95:5. Stir evenly to make it a suspension. Pasteurized at 85°C to obtain a sterilized corn germ meal suspension;

[0037] (2) The sterilized corn germ meal suspension obtained in step (1) is naturally cooled, and when the suspension is stable to 40°C, the pH of the solution is adjusted to 8.0-8.5 with a 0.1 mol / l NaOH solution;

[0038] (3) Add 0.04kg composite protease, the added composite protease is a mixture of alkaline protease Alacalase-2.40.01kg and Protamex protease 0.03kg; stir slowly at a temperature of 55°C at a stirring speed of 12 revolutions / min and maintain for 4 hours. Enzymolysis to obtain enzymolysis solution;

[0039] (4) Add the alkaline protease Alacalase-2.4...

Embodiment 2

[0045] A method for extracting protein powder from corn germ meal includes the following steps:

[0046] (1) After extracting corn oil, 5 kg of corn germ meal is crushed and passed through a 200-mesh sieve. Add 95 kg of water. The weight ratio of the added water to the corn germ meal is 95:5. Stir evenly to make it into a suspension at 85°C. Sterilize to obtain the corn germ meal suspension after disinfection;

[0047] (2) The sterilized corn germ meal suspension obtained in step (1) is naturally cooled, and when the suspension is stable to 40°C, the pH of the solution is adjusted to 8.0-8.5 with a 0.1 mol / l NaOH solution;

[0048] (3) Add 0.04kg of composite protease, the added composite protease is a mixture of alkaline protease Alacalase-2.40.016kg and Protamex protease 0.024kg; stir slowly at a temperature of 40°C, stirring at a speed of 10 revolutions / min, and keep it for 4 hours. Enzymolysis to obtain enzymolysis solution;

[0049] (4) Add the alkaline protease Alacalase-2.4 so...

Embodiment 3

[0055] A method for extracting protein powder from corn germ meal includes the following steps:

[0056] (1) Mix 2.5 kg of corn germ meal after steaming, frying, squeezing and extracting corn oil and 2.5 kg of corn germ meal after extracting corn oil. After crushing and passing through a 200-mesh sieve, add 95kg of water. The weight ratio is 95:5, stir evenly to make a suspension, and pasteurize at 85°C to obtain a sterilized corn germ meal suspension;

[0057] (2) The sterilized corn germ meal suspension obtained in step (1) is naturally cooled, and when the suspension is stable to 40°C, the pH of the solution is adjusted to 8.0-8.5 with a 0.1 mol / l NaOH solution;

[0058] (3) Add 0.04kg of complex protease, the added complex protease is a mixture of alkaline protease Alacalase-2.40.01kg and Protamex protease 0.03kg; stir slowly at 60°C, the stirring speed is 12 revolutions / min, keep for 4h, proceed Enzymolysis to obtain enzymolysis solution;

[0059] (4) Add the alkaline protease A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com