Method for in-situ leaching of rare-earth ores from weathering crust elution-deposited rare earth ore

A weathered crust leaching type and in-situ leaching technology, which is applied in the direction of improving process efficiency, can solve the problems of rare earth concentration tailing in the leachate, product purity not meeting the requirements, and poor permeability of the leachate solution, etc., to improve the rare earth concentration. The effects of improving the leaching rate, shortening the outflow time, and reducing geological disasters of ore body landslides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

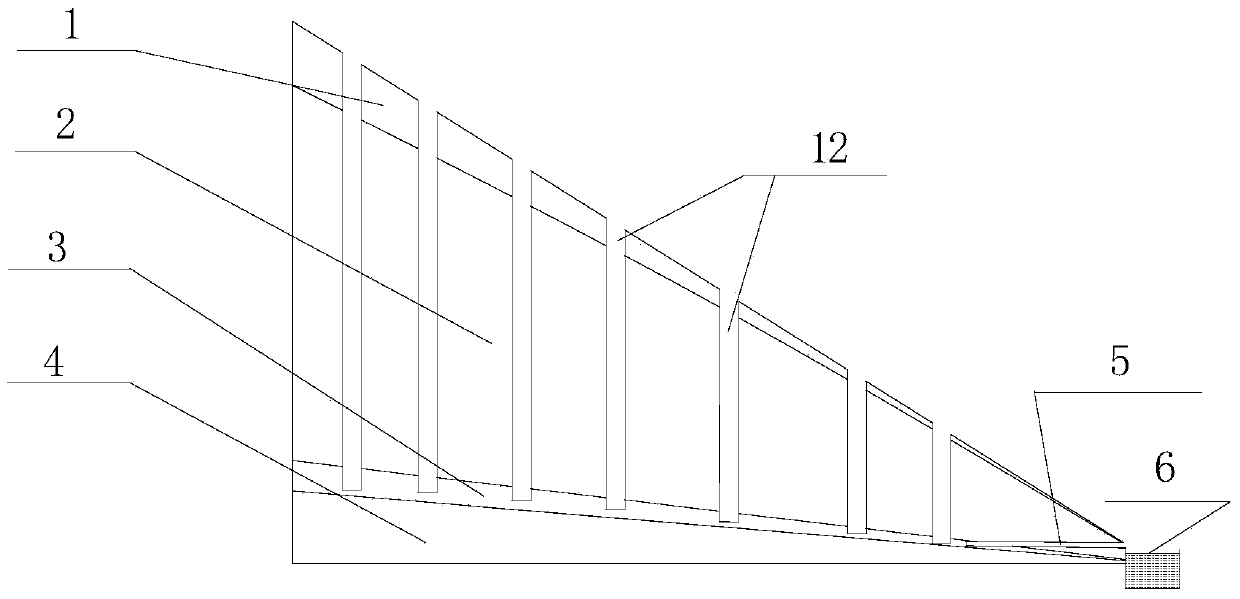

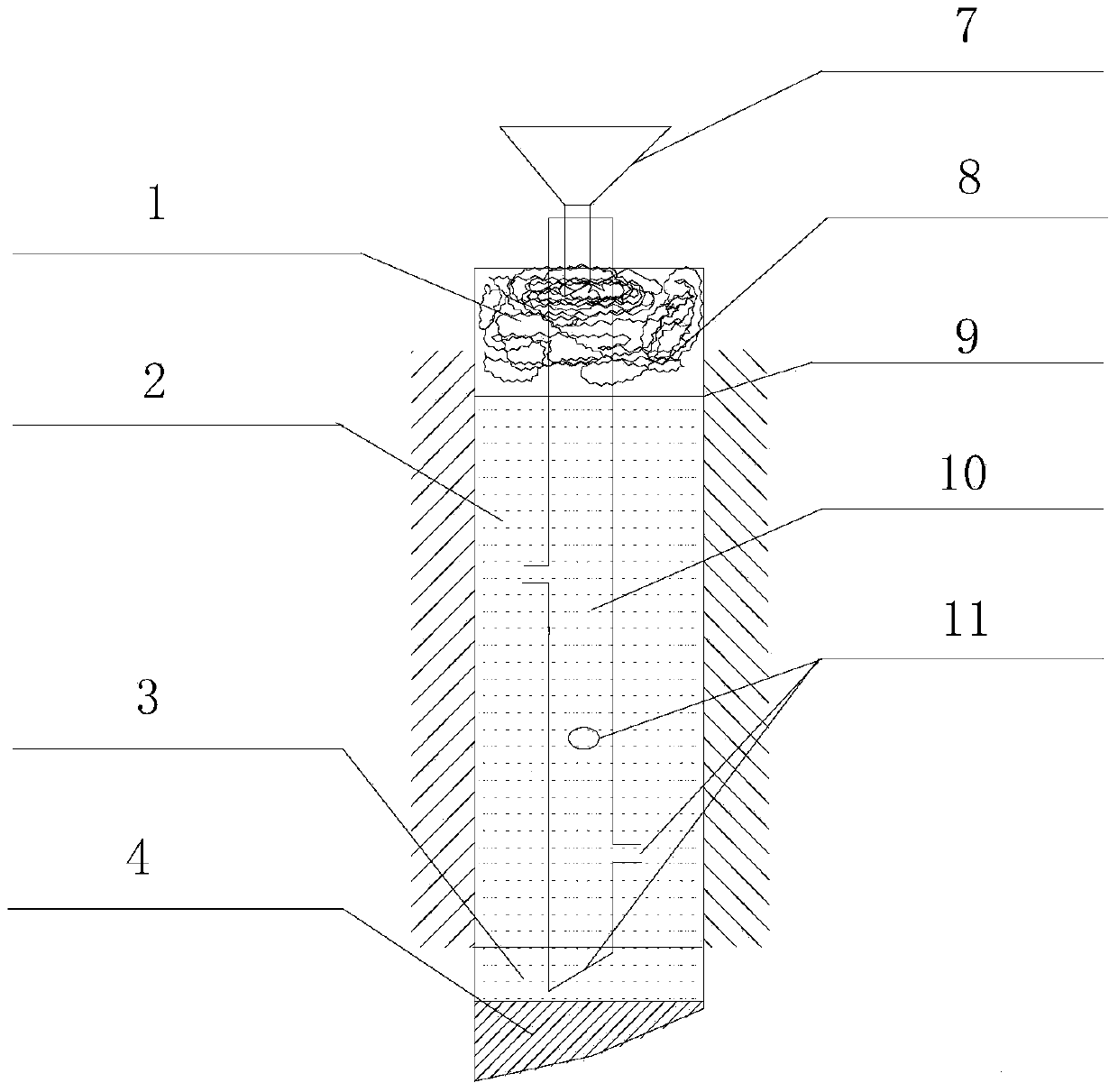

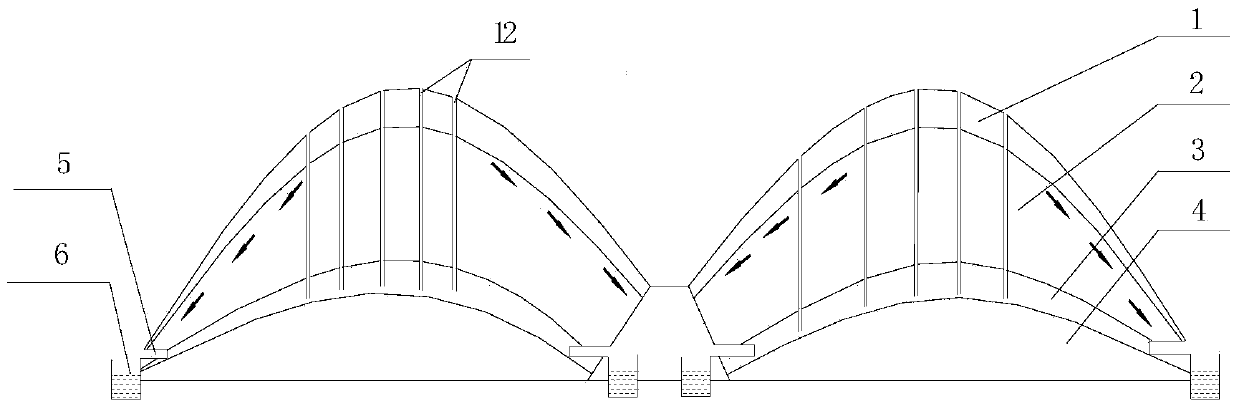

Embodiment 1

[0039] A weathering crust elution type rare earth ore in Guangdong, the rare earth composition is medium yttrium rich europium type. Rare earth average grade RE 2 o 30.086%. A hole 12 with a diameter of 15 cm is drilled under the ore body forest, and the ore taken out is judged by the hand-holding method to determine the depth of the hole entering the ore body. After holding the ore tightly, let go. If the ore is clumped, it is humus layer 1. If it is cracked or scattered It is full regolith 2 ore. It is measured that the humus layer 1 of the ore body is about 2m, the depth of the fully weathered layer 2 is about 18m, and the depth of the semi-weathered layer 3 is about 0.8m. When it touches the bedrock 4, the drilling 12 is stopped. After determination, the grades of rare earth ores in humic layer 1, fully weathered layer 2 and semi-weathered layer 3 are 0.025%, 0.089% and 0.028%, respectively. The holes 1212 of the ore body are arranged in a grid, and are only drilled al...

Embodiment 2

[0041] A weathering crust elution type rare earth ore in Guangdong, the rare earth composition is medium yttrium rich europium type. Rare earth average grade RE 2 o 3 0.078%. A hole with a diameter of 8 cm is drilled under the ore body forest, and the ore taken out is judged by the hand-holding method to determine the depth of the hole entering the ore body. After holding the ore tightly, let it go. If the ore clumping is humus layer 1, if it is cracked or scattered For the full regolith 2 ore. It is measured that the humus layer 1 of the ore body is about 1.2m, the depth of the fully weathered layer 2 is about 21m, and the depth of the semi-weathered layer 3 is about 0.5m. When it touches the bedrock 4, the drilling is stopped. The rare earth grades of rare earth ores in humic layer 1, fully weathered layer 2 and semi-weathered layer are 0.023%, 0.082% and 0.026%, respectively. The holes 12 of the ore body are arranged in a grid, and are drilled only along the ridge, wit...

Embodiment 3

[0043] A weathering crust leaching type rare earth mine in Jiangxi, the rare earth composition is medium yttrium rich in europium, and the average grade of rare earth is RE 2 o 3 0.093%. A hole 12 with a diameter of 10 cm is drilled under the ore body forest, and the ore taken out is judged by the hand-holding method to determine the depth of the hole entering the ore body. After holding the ore tightly, let go. If the ore is clumped, it is a humus layer 1. If it is cracked or scattered It is full regolith 2 ore. It is measured that the humus layer 1 of the ore body is about 0.6m, the depth of the fully weathered layer 2 is about 14m, and the depth of the semi-weathered layer 3 is about 0.6m. When it touches the bedrock 4, the drilling is stopped. The rare earth grades of rare earth ores in humic layer 1, fully weathered layer 2 and semi-weathered layer 3 are 0.026%, 0.103% and 0.024%, respectively. The holes 12 of the ore body are arranged in a grid, and are only drilled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com