Anionic nonionic gemini surfactant and its preparation method and application

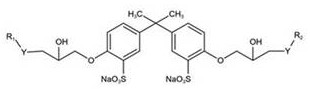

A gemini surface, anion and non-ionic technology, applied in the preparation of ether, sulfonic acid, sulfonate, etc., can solve the problems of long synthetic route of gemini surfactant, unsuitable for industrial production, and limited field application, etc., and achieve easy formation Effects of micelles, good application properties, and good calcium soap dispersion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

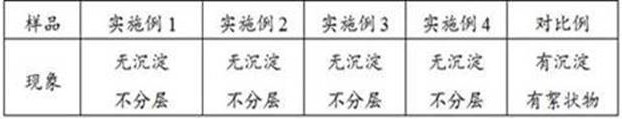

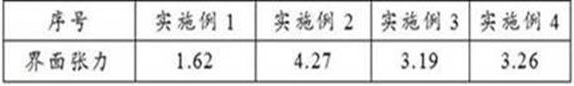

Examples

Embodiment 1

[0051] Embodiment 1: the synthesis of two (octadecyl polyoxyethylene ether (5)-hydroxypropyl)-bisphenol A-sodium disulfonate surfactant

[0052] Add 1.0mol stearyl alcohol polyoxyethylene ether (5EO) into a 2000mL four-neck bottle reaction kettle, heat up to 50-70°C, and after nitrogen replacement, add a catalyst of 1% mass of raw material boron trifluoride ether for complexation Add 0.5-0.6mol of bisphenol A diglycidyl ether dropwise, finish dropping within 0.5-1.5h, keep at 80°C and continue to react for 8h to obtain a nonionic gemini surfactant intermediate;

[0053] Lower the temperature of the above product to 30-50°C, slowly add 3.0mol concentrated sulfuric acid sulfonating agent dropwise under rapid stirring, drop it within 1.5-2.5h, continue to control the temperature at 30-50°C for 3-5h, and the product is treated with sodium hydroxide The solution is hydrolyzed and the pH is adjusted to neutral to obtain the anionic nonionic gemini surfactant sulfonate. The total yi...

Embodiment 2

[0054] Embodiment 2: the synthesis of two (dodecylphenol polyoxyethylene ether (8)-hydroxypropyl)-bisphenol A-bissulfonate sodium surfactant

[0055] Add 1.0mol dodecylphenol polyoxyethylene ether (8EO) into a 2000mL four-neck bottle reactor, heat up to 50-70°C, and after nitrogen replacement, add 10% sodium methoxide solution containing 2% of the raw material mass as Catalyst, remove the methanol solvent brought by the catalyst in a vacuum, add 0.5-0.6mol bisphenol A diglycidyl ether dropwise, drop it within 1.5-3.0h, raise the temperature and keep at 150°C to continue the reaction for 5h, and obtain a nonionic gemini surfactant Intermediate;

[0056] Lower the temperature of the above product to 30-40°C, slowly add 2.5mol of oleum sulfonating agent dropwise under rapid stirring, and drop it within 1.5-2.5h, continue to control the temperature at 30-40°C for 3-5h, and the product is oxidized by hydrogen The potassium solution is hydrolyzed and the pH is adjusted to neutral t...

Embodiment 3

[0057] Embodiment 3: the synthesis of two (oleamide polyoxyethylene ether (7)-hydroxypropyl)-bisphenol A-bissulfonate sodium surfactant

[0058] Add 1.0mol oleic acid amide polyoxyethylene ether (7EO) into a 2000mL four-neck bottle reaction kettle, heat up to 50-70°C, and after nitrogen replacement, add 10% sodium hydroxide ethanol solution with a content of 2% of the raw material mass as Catalyst, remove the ethanol solvent brought by the catalyst in a vacuum, add 0.5-0.6mol bisphenol A diglycidyl ether dropwise, drop it within 1.5-3.0h, keep the temperature at 150°C and continue the reaction for 3h to obtain a nonionic gemini surfactant Intermediate;

[0059] Lower the temperature of the above product to 30°C, slowly add 2.0mol chlorosulfonic acid sulfonating agent dropwise under rapid stirring, and finish the drop within 1.5-2.5h, continue to control the temperature at 30-50°C for 3-5h, and the product is hydrolyzed with concentrated ammonia water And adjust the pH to neut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com