Pile type continuous rigid frame bridge and construction method thereof

A pile and rigid frame technology, applied in the field of continuous rigid frame bridges and their construction, can solve the problems of not setting piers, limiting the height of piers, increasing the flexibility of piers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

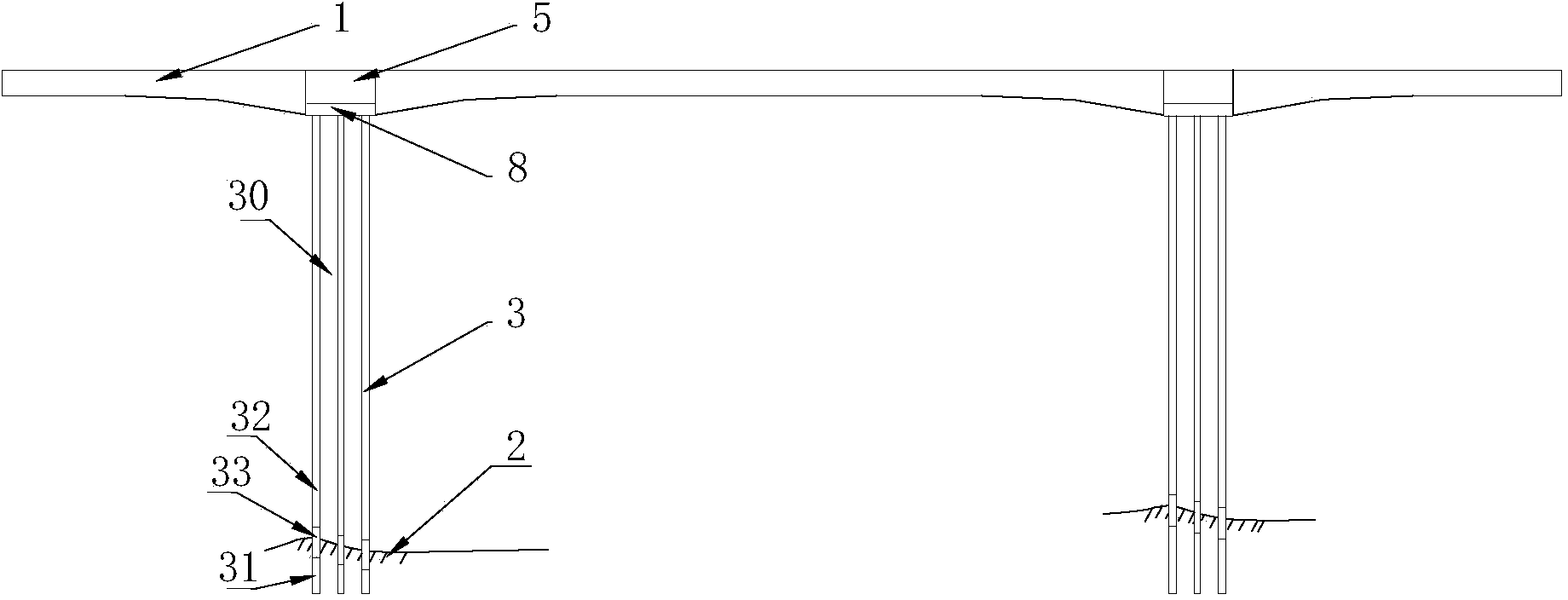

[0117] Such as image 3 As shown, a main beam connection part 5 is arranged between two adjacent span main beams 5, and a pile group foundation 30 is installed and poured under the main beam connection part 5, and the pile group foundation 30 is composed of a group of cast-in-place piles 3 . The top end of each cast-in-place pile 3 is provided with a bottom plate 8 integrated with the girder connecting portion 5 of the bridge deck girder 1 . In order to ensure that the top of the cast-in-situ pile 3 is consolidated with the main beam connection part 5, the horizontal reinforcement at the bottom of the bottom plate 8 is reinforced according to the reinforcement requirements of the cap 6 of the high-pier continuous rigid frame bridge, and the thickness of the main beam connection part 5 and the bottom plate 8 The sum is not less than the thickness of the cap 6 of the continuous rigid frame bridge with high piers.

[0118] The cast-in-place pile 3 is divided into three sections...

Embodiment 2

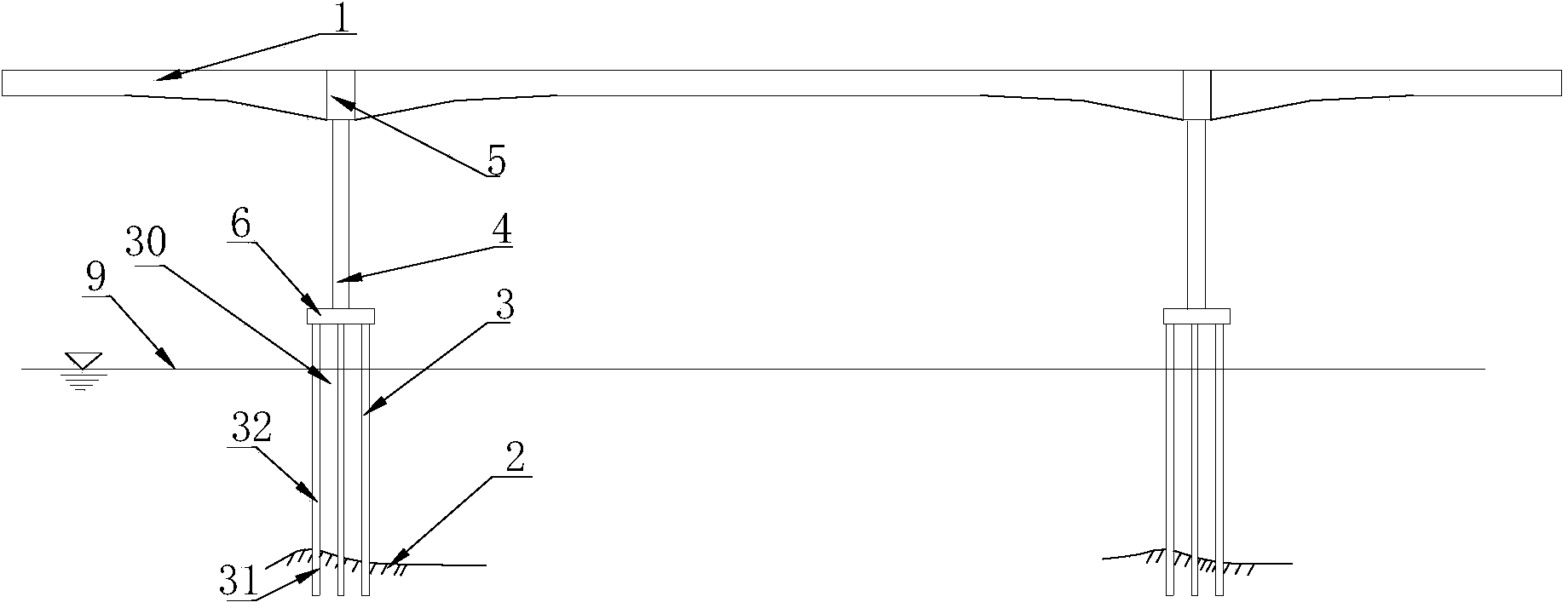

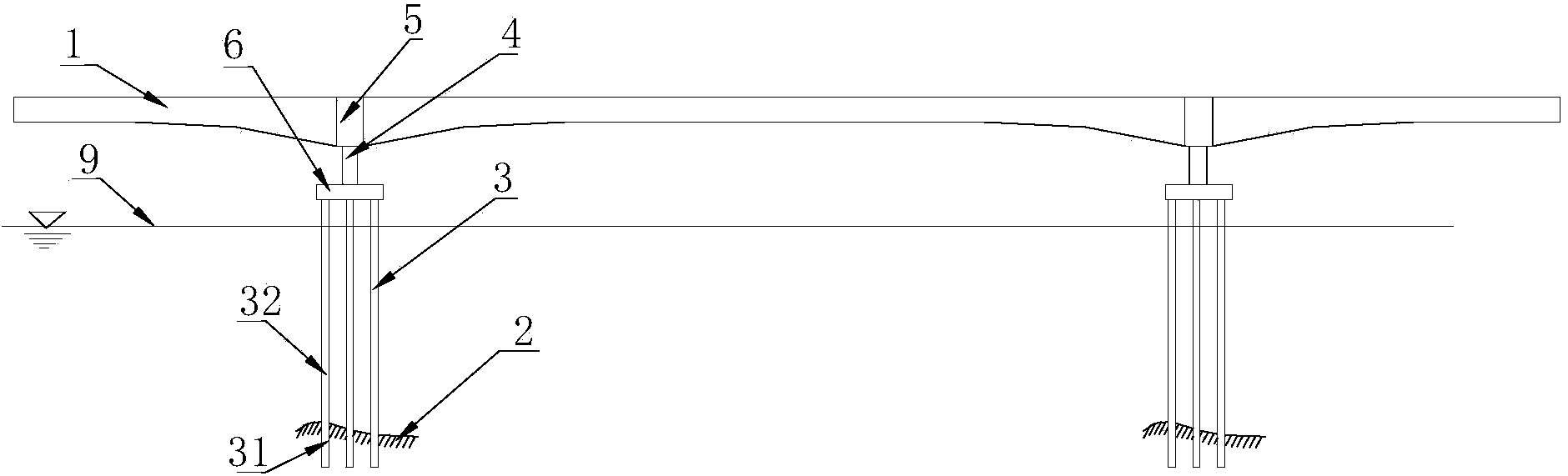

[0131] Such as Figure 4 As shown, the difference between the present embodiment and the first embodiment is that when the width of the deck girder 1 is smaller than the width of the pile group foundation 30, such as Figure 5 As shown, if according to the method of Embodiment 1, part of the cast-in-situ piles 3 cannot be directly connected with the main beam connection portion 5, for this reason, a cap 6 is arranged on the top of the pile group foundation 30, and the cap 6 and the pile group foundation are formed. All cast-in-situ piles 3 of 30 are connected to form an integral support structure, and an upper cap 7 is arranged on the above-mentioned cap 6, and the upper cap 7 is connected with the main beam connection part 5, and the width of the upper cap 7 is the same as that of the main beam 1 The widths are compatible, so that the connection between the main girder 1 of the bridge deck and the cast-in-place pile 3 can be solved.

[0132] In this embodiment, the height of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com