Pile body stress testing device of static-pressure high-strength pre-stress concrete pipe pile

A technology for concrete pipe piles and stress testing, which is applied in the direction of measuring the change force of optical properties when the material is stressed, can solve the problems of low reliability and survival rate, large environmental factors, and low survival rate. , to achieve the effects of easy quasi-distributed and automatic monitoring, strong anti-electromagnetic field interference ability, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

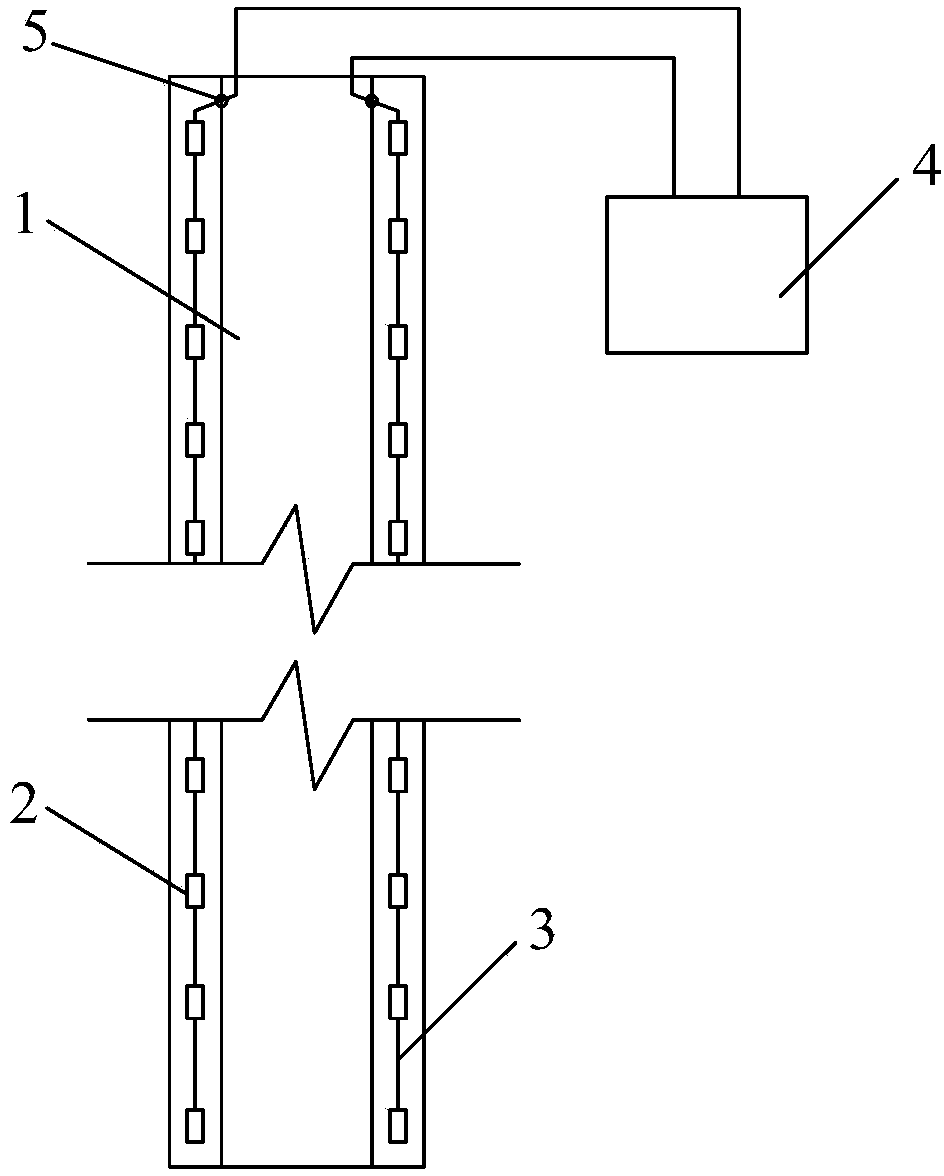

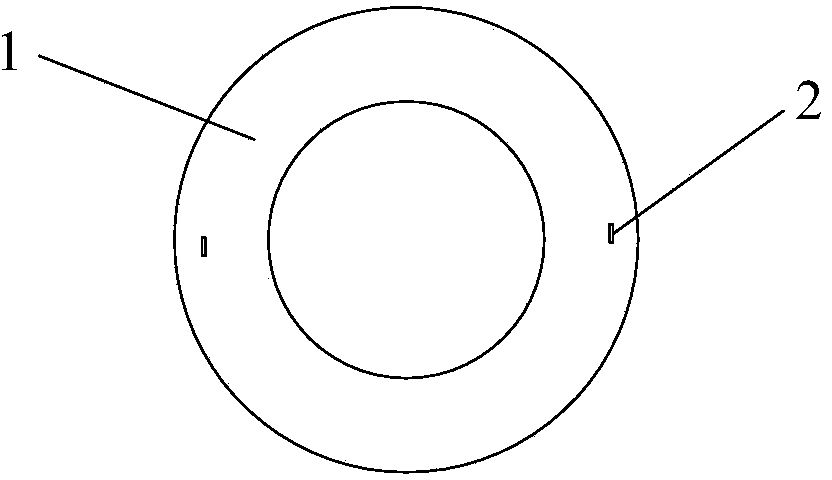

[0016] The main structure of this embodiment includes a high-strength prestressed concrete (PHC) pipe pile 1, a fiber Bragg grating (Fiber Bragg Grating, FBG for short) sensor 2, an armored optical cable 3, a data acquisition system 4, and a pile body bore 5; Shallow grooves are cut inside the high-strength prestressed concrete (PHC) pipe pile 1 constructed by the compression method, and the optical fiber Bragg grating sensor 2 and the armored optical cable 3 are welded in series in a quasi-distributed manner, and the optical fiber Bragg grating sensor 2 and the armored optical cable 3 are connected in series Implanted in the shallow groove of the high-strength prestressed concrete (PHC) pile 1 and encapsulated with epoxy resin mixture for protection, the optical fiber Bragg grating sensor 2 is placed at the position of the high-strength prestressed concrete (PHC) pile 1 according to the soil layer to be tested Lay out at the same elevation; the inside of the top of the high-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com