Formation method of soft-packed lithium ion battery

A technology of lithium-ion batteries and ion batteries, which is applied in the field of formation of soft-packed lithium-ion batteries, can solve problems such as battery flatulence, small lithium titanate particles, and hidden dangers of battery safety, so as to avoid gas residues, promote reactions, and achieve high compactness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

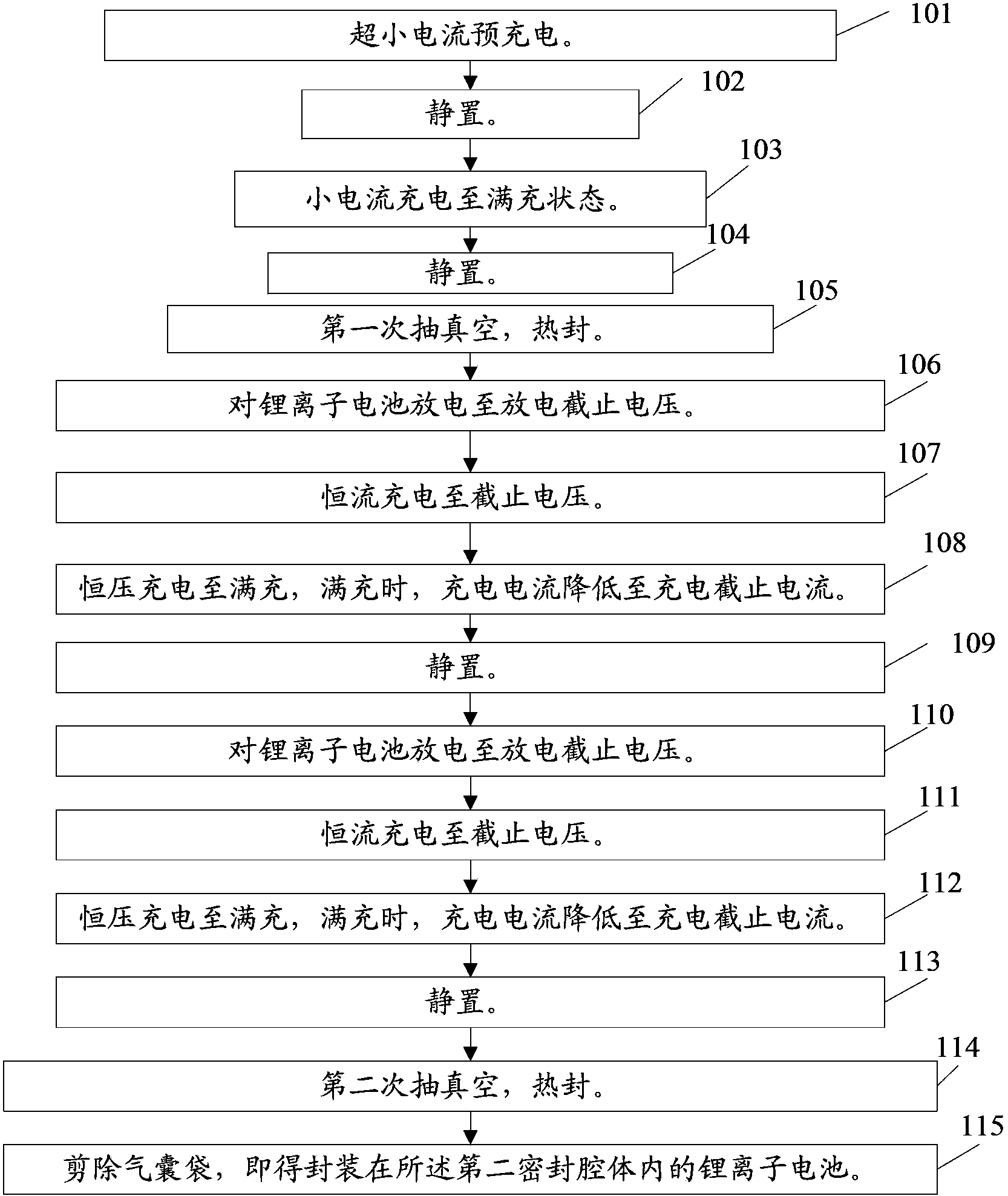

[0028] This embodiment provides a method for forming a soft-packed lithium-ion battery after liquid injection and sealing, see figure 1 As shown, the method mainly includes the following processes:

[0029] Step 101: pre-charging with ultra-low current.

[0030] The lithium-ion battery behind the liquid-filled sealed case is charged to a predetermined less-full-charge state with the first charging current. For example, the lithium-ion battery can be precharged with an ultra-low current of any rate of 0.3-0.05 until the capacity of the lithium-ion battery reaches about 60-70% of the total capacity.

[0031] In the test of this embodiment, the inventor specifically charged the lithium-ion battery with a current of 0.05 times for 260 minutes, so that its capacity reached 30% of the total capacity.

[0032] In this embodiment, the use of the ultra-low current charging is beneficial to slow down the reaction between the internal electrode material and the electrolyte of the lithi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com