Material increase manufacturing method based on high-speed spray forming of multi-material particles

An additive manufacturing and high-speed jetting technology, applied in the field of additive manufacturing, can solve problems such as three-dimensional solid parts, strength and precision research of manufactured parts, and additive manufacturing of multi-material composite structural parts that have not yet been carried out, so as to eliminate boundaries. The effect of the loss phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

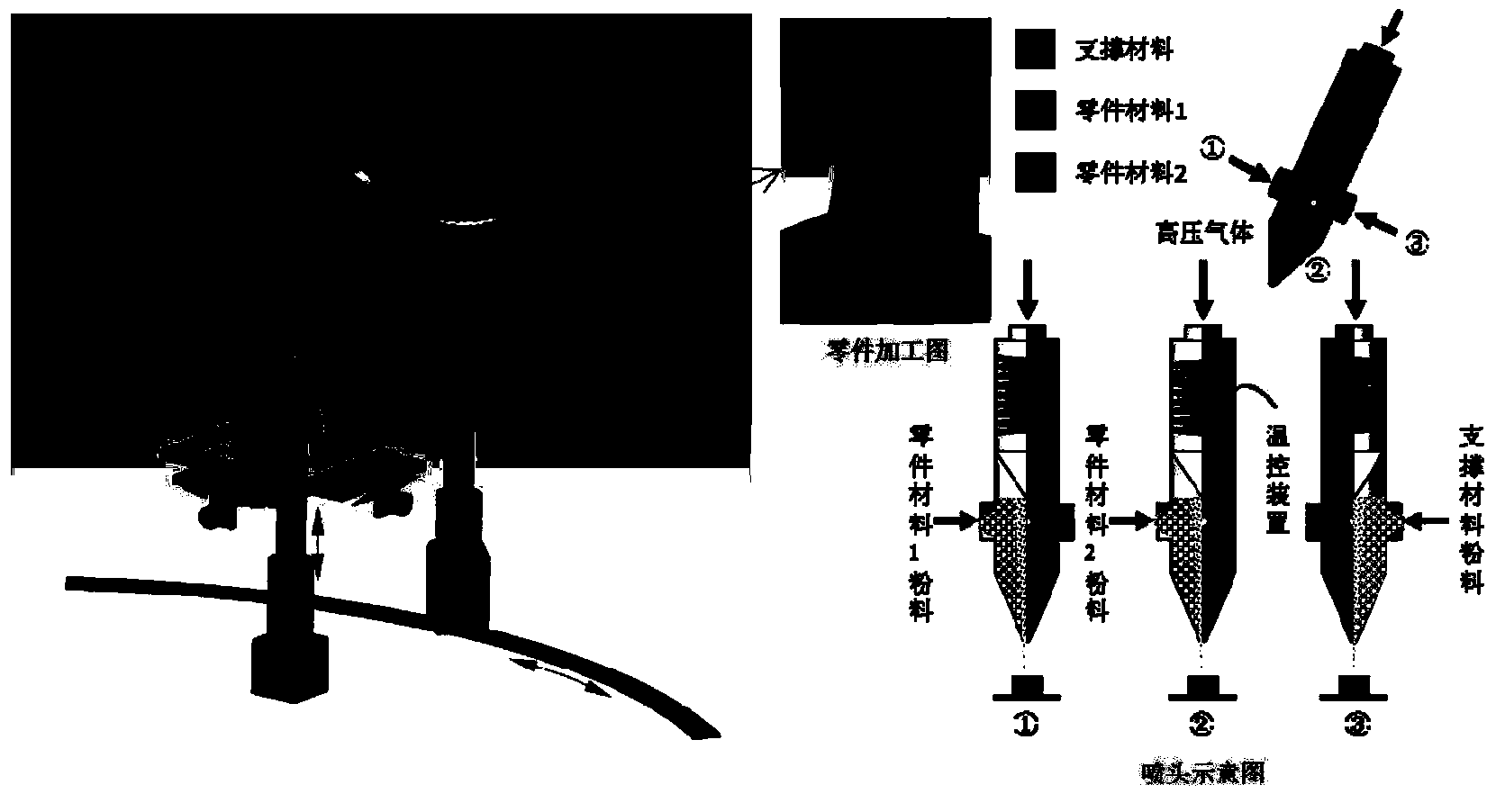

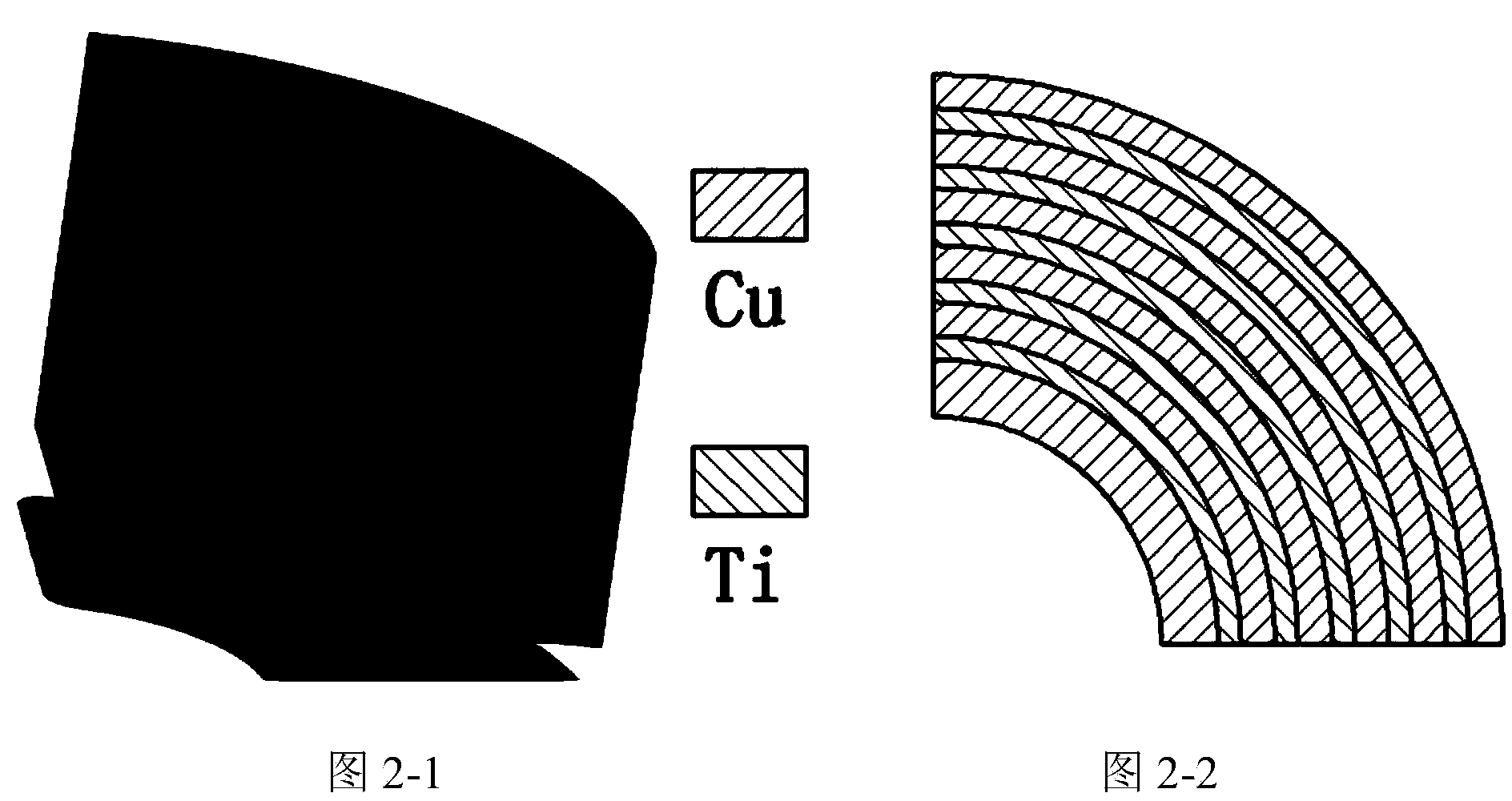

[0040] see figure 1 , Figure 2-2 , diagram 2-1 , high-speed spray forming to prepare rapid prototyping parts with complex structures of copper and titanium particles, including the following steps:

[0041] 1. According to theoretical calculation and structural design, use Pro / E to complete the 3D modeling of the part and save it in STL file format;

[0042] 2. Uniformly seal the CAD model, obtain the information of the layered section material of the model, and write the motion program of the spray gun and the platform;

[0043] 3. Load 20um spherical copper particles and titanium particles into the screw powder feeder respectively, adjust the conveying efficiency, and control the powder feeding rate at 5kg / h;

[0044] 4. In order to improve the efficiency of particle acceleration and save costs, use a mixed gas of nitrogen and helium with a mass fraction of He of 10%, transport the gas from the powder feeder, and use two heaters to preheat the temperature of the working...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com