Methanol and C4-to-olefin quenched water and washing water airtight coupling treatment method and device

A technology of quenching water and washing water, which is applied in the field of coal conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

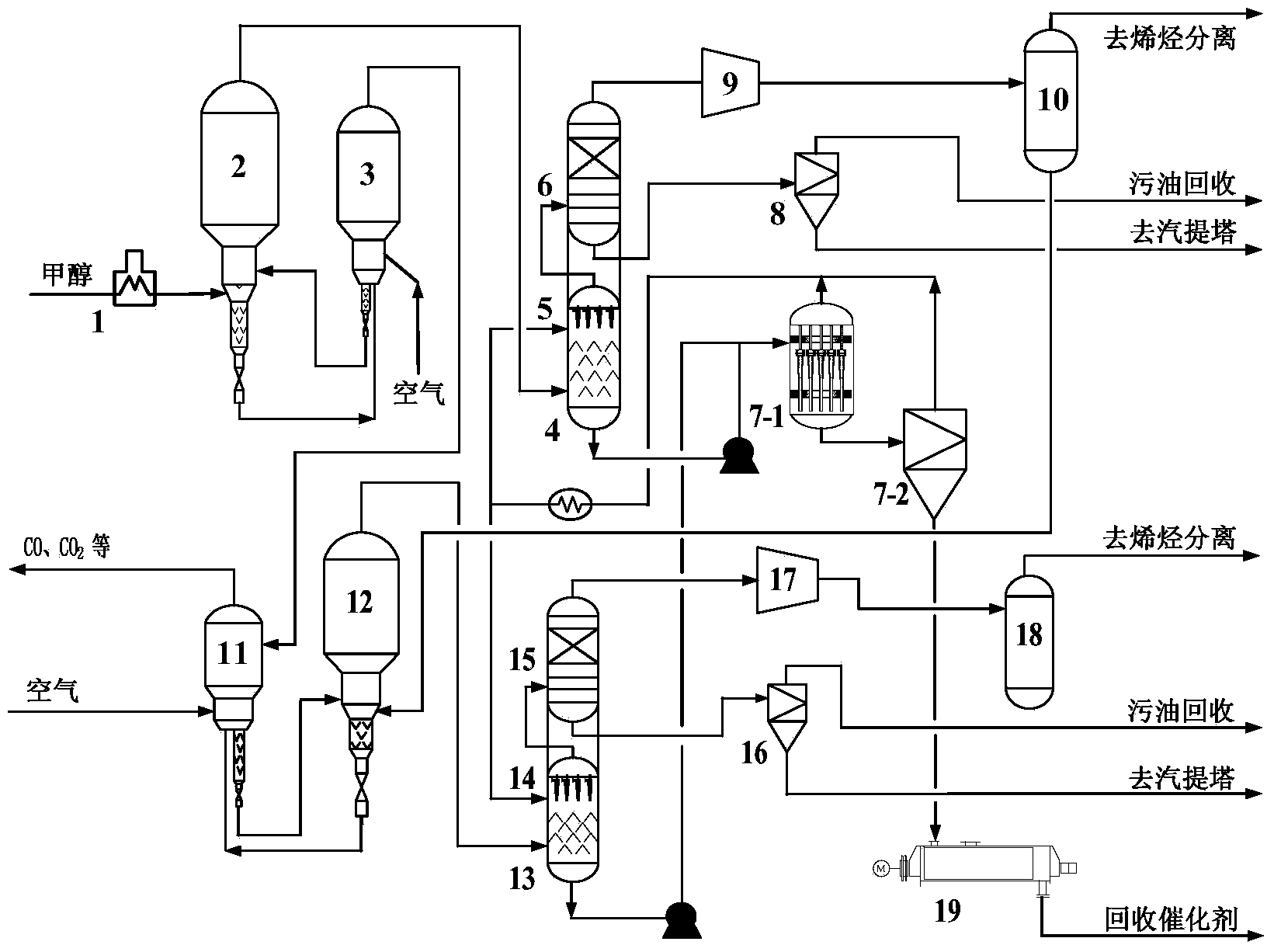

Embodiment 1

[0058] In a 1,800,000-ton / year methanol-to-600,000-ton / year olefin process, according to the method of the present invention, the quenching water and washing water closed coupling treatment device for methanol and carbon four olefins are used, (1) to the top of the quenching tower , The reaction gas at the top of the C4 quenching tower is swirled and purified to remove the catalyst particles and liquid hydrocarbons entrained by the reaction gas; the purified reaction gas is washed with water to improve the water quality of the washing water; (2) the bottom of the quenching tower , The quenched water containing catalyst particles at the bottom of the C4 quenching tower is subjected to liquid-solid separation and concentration, and the separated and purified quenched water is returned to the quenching tower after heat exchange to realize the recycling of the quenched water; (3) the separated and concentrated The catalyst is dried to recover the catalyst particles; and (4) the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com