Heat vulcanization adhesive and preparation method thereof

An adhesive and thermal vulcanization technology, applied in the direction of adhesives, halogen rubber derivative adhesives, adhesive types, etc., can solve the problems of cumbersome process, low bonding strength and 90° peel strength, etc., and achieve simple construction technology, Enhanced adhesive strength and 90° peel strength, effects of high adhesive strength and 90° peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

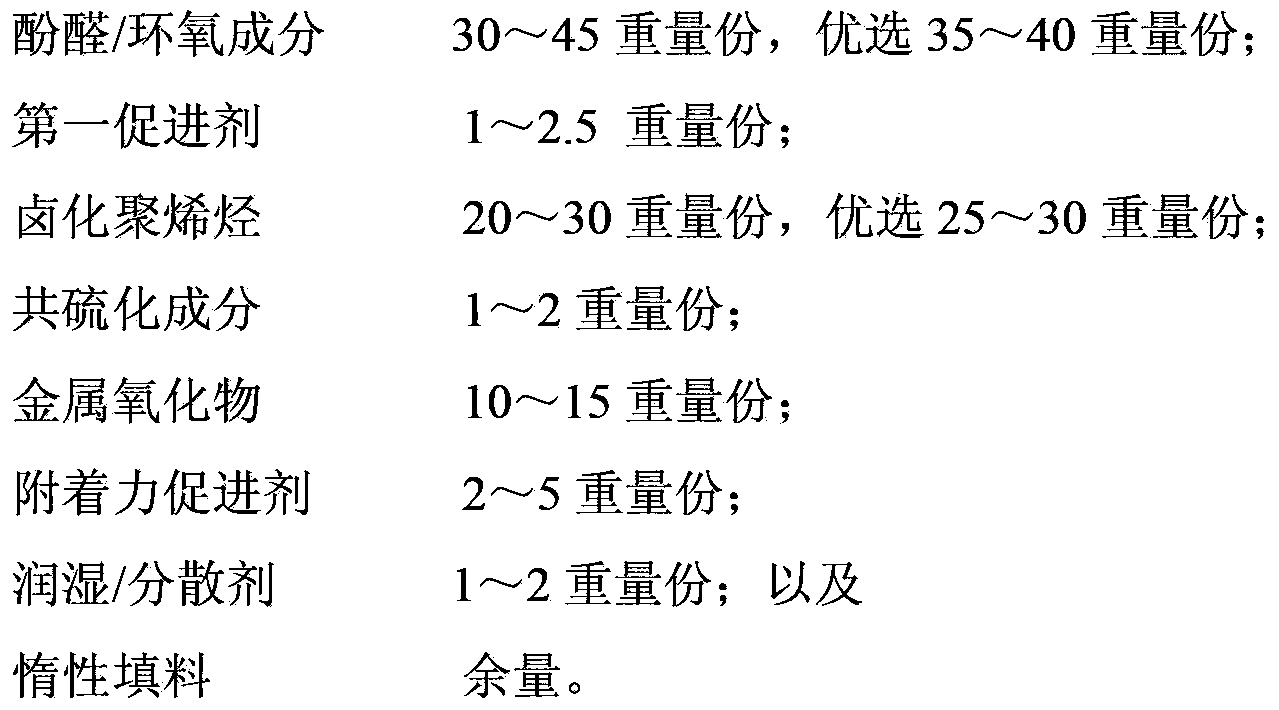

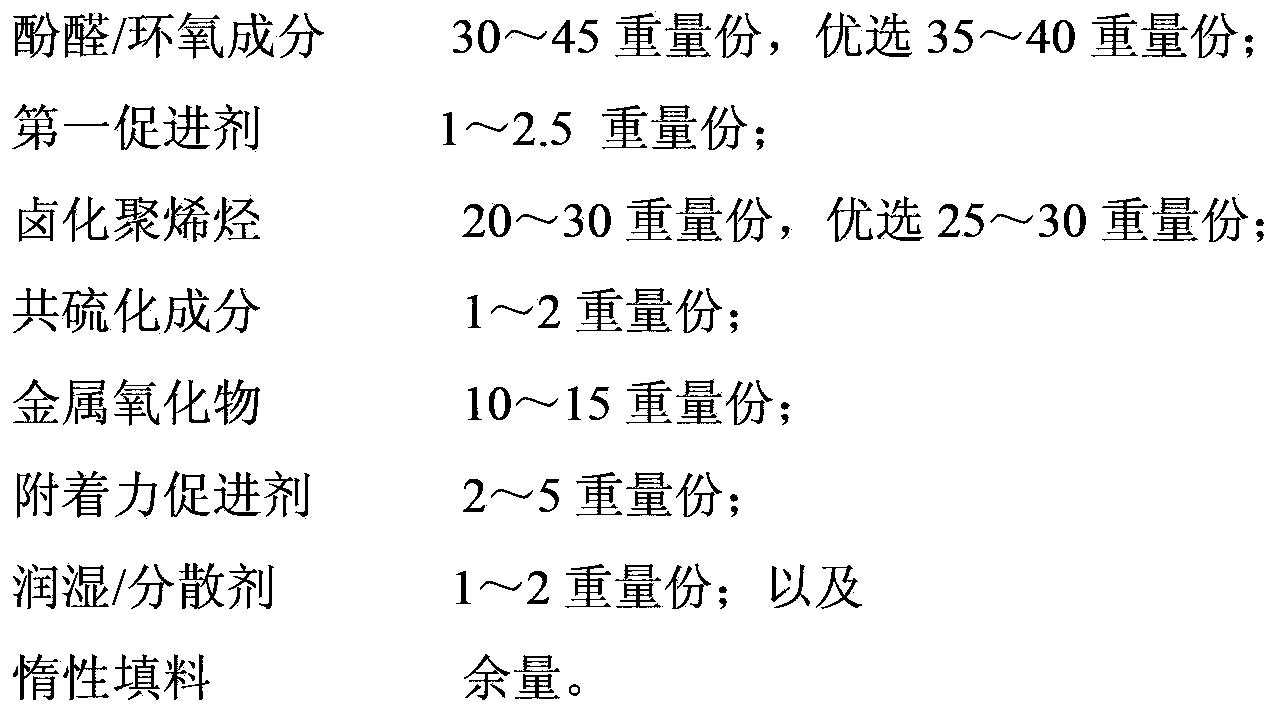

[0048] The dry weight of the thermally vulcanized adhesive in this embodiment is 100 parts by weight, and the solid content is 20% by weight.

[0049] The preparation method is as follows:

[0050] Step a: Weigh metal oxides (3 parts by weight ZnO, 10 parts by weight MgO and 2 parts by weight TiO 2 ) and solid inert filler (10 parts by weight of ceramic microspheres, 6 parts by weight of silicon dioxide and 3 parts by weight of carbon black), the above components were placed in an oven and dried at 60 ° C for 24 hours;

[0051] Step b: Add the mixed solvent into the mixer, add 1.5 parts by weight of wetting / dispersing agent and 2.5 parts by weight of adhesion promoter (chlorinated polyolefin); wherein the mixed solvent is a mixture of xylene and acetone, xylene: Acetone=2:1 (weight ratio);

[0052] Step c: Add the phenolic / epoxy component and the first accelerator component (10 parts by weight bisphenol A type novolac epoxy resin, 10 parts by weight tetrahydrophthalate bisgl...

Embodiment 2

[0058] The dry weight of the thermally vulcanized adhesive in this embodiment is 100 parts by weight, and the solid content is 30% by weight.

[0059] The preparation method is the same as in Example 1, wherein the phenolic / epoxy component and the first accelerator component (15 parts by weight of tetraglycidyl-4,4'-diaminodiphenylmethane, 15 parts by weight of allyl bisphenol A-type ring Oxygen resin, 2.5 parts by weight octylphenolic tackifying resin, 7.5 parts by weight brominated octylphenolic vulcanization resin and 2.0 parts by weight 2-ethyl-4-methylimidazole); halogenated polyolefin and co-vulcanization components (15 parts by weight Chlorinated natural rubber S170, 15 parts by weight of chlorosulfonated natural rubber CSM30 type, 1 part by weight of DCP and 0.5 parts by weight of Qiulan parent accelerator); metal oxide (5 parts by weight of ZnO, 5 parts by weight of MgO and 2 parts by weight of TiO 2 ); solid inert filler (5 parts by weight of ceramic microspheres, 5...

Embodiment 3

[0064] The dry weight of the thermal vulcanization adhesive in this embodiment is 100 parts by weight, and the solid content is 40% by weight.

[0065] The preparation method is the same as in Example 1, wherein the novolac epoxy component and the first accelerator component (20 parts by weight of o-cresol type novolak epoxy resin, 10 parts by weight of tetrahydrophthalic acid diglycidyl ester, 5 parts by weight of terpene phenolic tackifying resin, 5 parts by weight brominated octyl phenolic vulcanization resin and 2.0 parts by weight 2-methylimidazole); halogenated polyolefin and co-vulcanization components (15 parts by weight chlorinated natural rubber S170 and 15 parts by weight neoprene A -90 type, 1.5 parts by weight of BIPB and 0.5 parts by weight of bismaleimide); metal oxides (5 parts by weight of ZnO, 5 parts by weight of MgO and 5 parts by weight of TiO 2 ); solid inert filler (2.5 parts by weight of ceramic microspheres, 5 parts by weight of aluminum oxide and 1 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com