Renewable magnetic immobilized enzyme carrier and preparation method thereof

An immobilized enzyme carrier, magnetic technology, applied in the direction of immobilization on or in an inorganic carrier, etc., can solve the problems of increasing production cost, abandoning carrier, reducing activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: A kind of preparation method of regenerable magnetically immobilized enzyme carrier,

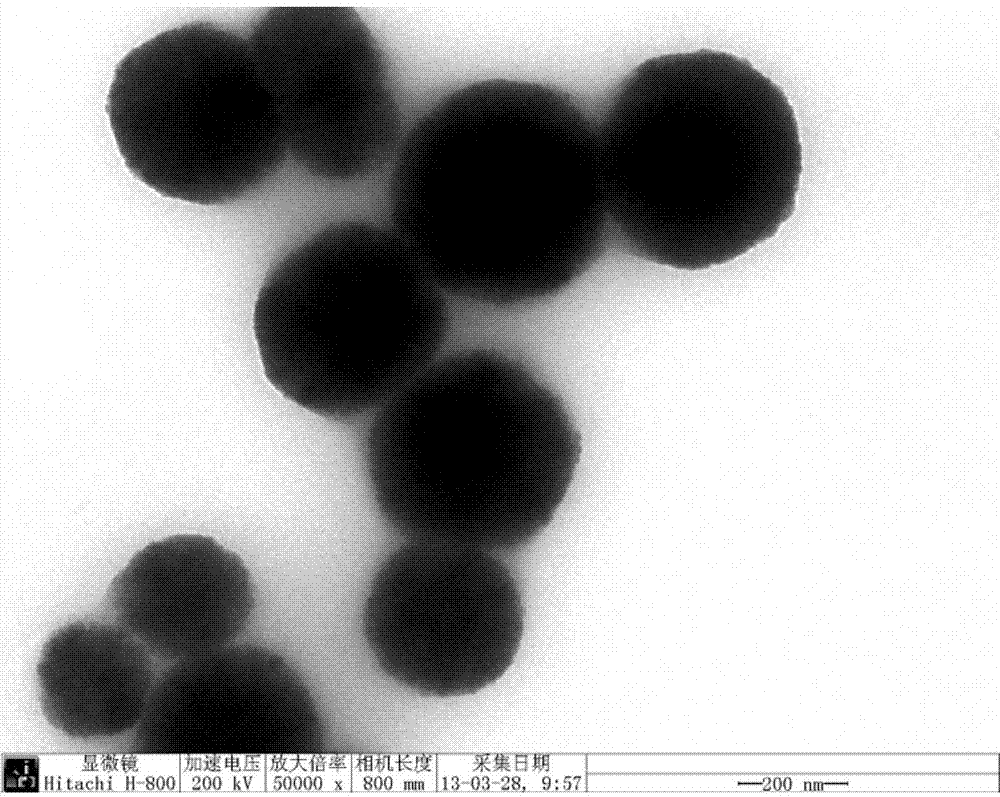

[0045] (a) Preparation of Fe 3 o 4 Magnetic nanoparticles (Fe 3 o 4 NPs):

[0046] Fe 3 o 4 Magnetic nanoparticles were synthesized by the following solvothermal method. Mix 3.24g FeCl under mechanical stirring 3 ·6H 2 O, 10.44g of sodium acetate, dissolved in 120mL of ethylene glycol solution; transfer the obtained yellow solution to a stainless steel reaction kettle lined with polytetrafluoroethylene, and react at 200°C for 12h; use an external magnetic field to separate and collect black magnetic Particles; the isolated product was washed with absolute ethanol for 4 times, then separated and collected, and placed at 60°C for complete volatilization for later use.

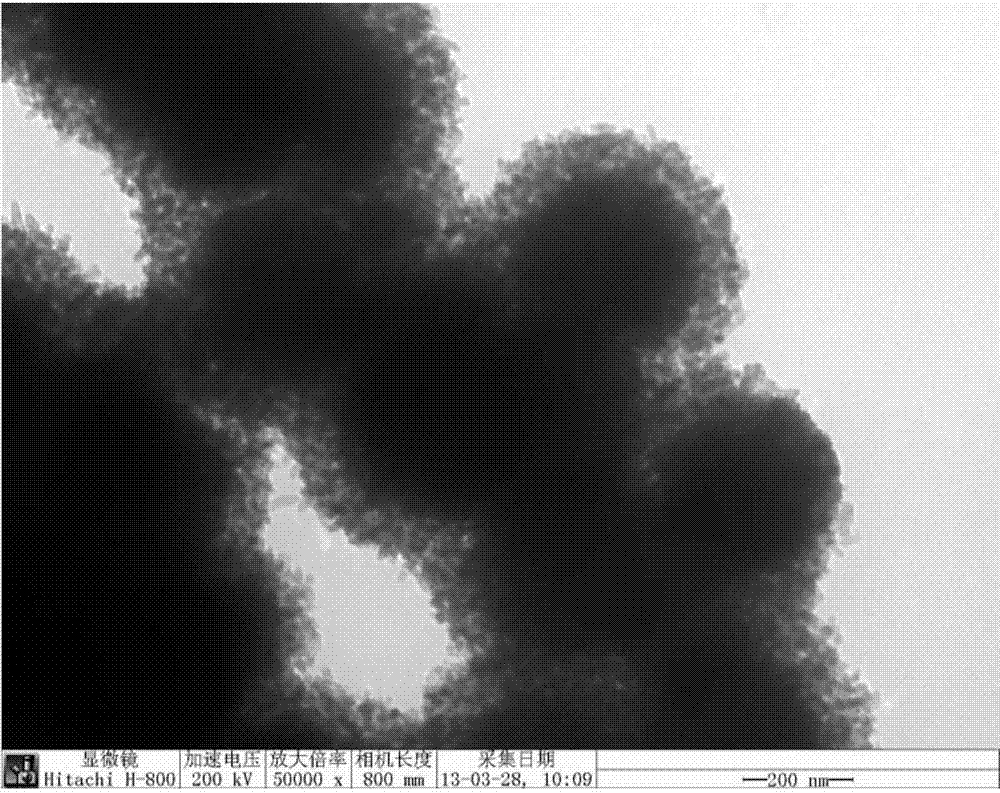

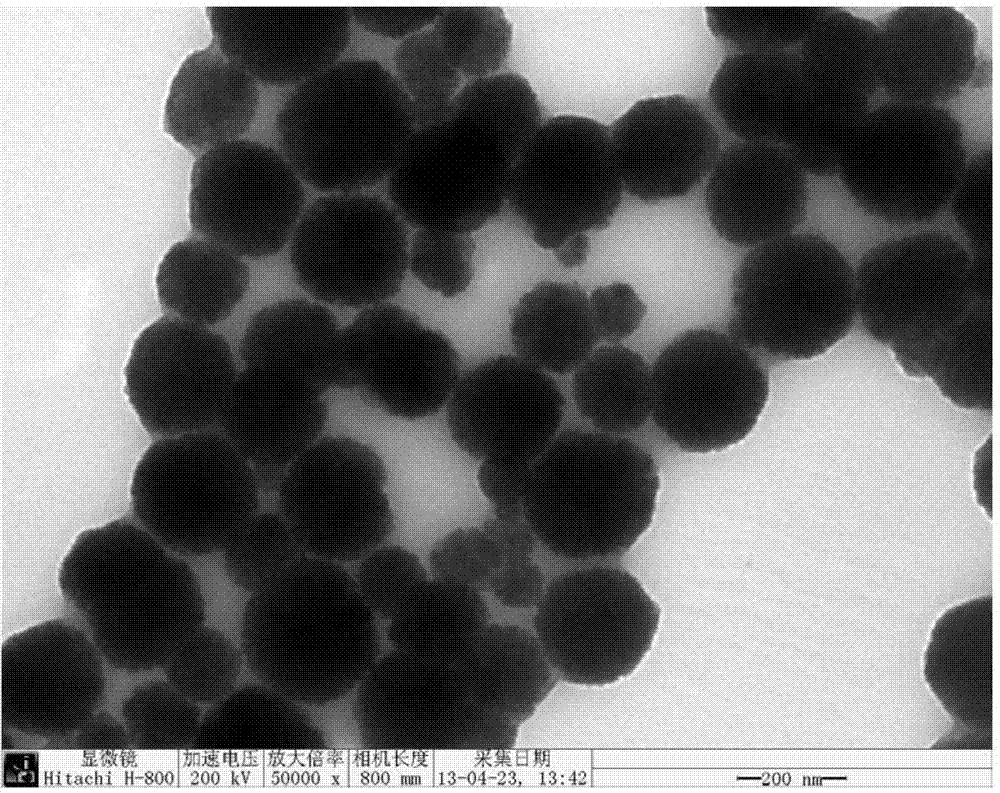

[0047] (b) Preparation of core-shell structure Fe 3 o 4 TiO 2 Magnetic colloidal nanoparticles (Fe 3 o 4 TiO 2 NPs):

[0048] 200 mg of Fe prepared in step (a) 3 o 4 NPs were added to a so...

Embodiment 2

[0059] Embodiment 2: a kind of preparation method of regenerable magnetically immobilized enzyme carrier,

[0060] Same as the steps of Example 1, the difference is that the step (e) of Example 1 is to connect the prepared carrier with horseradish peroxidase to detect the load of the carrier on the enzyme and the impact on the enzyme activity, while the embodiment The second is to link the carrier prepared according to steps (a) to (d) of Example 1 with laccase to detect the load of the carrier on laccase (EC1.10.3.2, Fluka) and the effect on enzyme activity. The results showed that Fe 3 o 4 TiO 2 The nanocomposite carrier loaded 98 ± 9 mg / g of laccase and retained 96 ± 4% of the activity of the free enzyme.

Embodiment 3

[0061] Embodiment 3: a kind of preparation method of regenerable magnetically immobilized enzyme carrier,

[0062] Same as the steps of Example 1, the difference is that the step (e) of Example 1 is to connect the prepared carrier with horseradish peroxidase to detect the load of the carrier on the enzyme and the impact on the enzyme activity, while the embodiment 3 is to connect the carrier prepared according to the steps (a) to (d) of Example 1 with alcohol dehydrogenase (EC1.1.1.1, Sigma) to detect the load of the carrier on the alcohol dehydrogenase and the effect on the enzyme activity . The results showed that Fe 3 o 4 TiO 2 The nanocomposite carrier loaded 105 ± 6 mg / g of alcohol dehydrogenase and retained 93 ± 5% of the activity of the free enzyme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com