Polyester pre-oriented yarn (POY) spinning method

A spinning box and monofilament technology, applied in the direction of melt spinning, spinneret assembly, filament forming treatment, etc., can solve the problems of poor spinning stability, large solidification point deviation, and short cleaning cycle , to achieve the effect of reducing monofilament hairiness and broken ends, reducing the working intensity of employees, and improving the uniformity of evenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

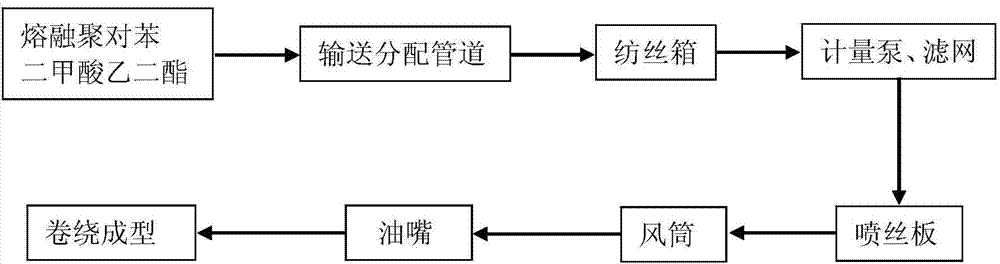

[0018] Embodiment 1: POY spinning process provided by the present invention, its flow process is as figure 1 As shown, the molten polyethylene terephthalate is transported to the spinning box through the conveying and distribution pipeline, accurately metered by the metering pump and filtered by a multi-layer filter, and is sprayed out from the spinneret holes on the spinneret to form multi-strand monofilaments Thin stream, using advanced circular air blowing to cool the thin stream of monofilaments ejected from the spinneret holes to form solid monofilaments, which are clustered and oiled by oil nozzles, and finally wound and formed.

[0019] The multi-layer filter screen adopted in the method is a 100 / 50 mesh two-layer filter screen that is rolled together to a 10-layer filter screen.

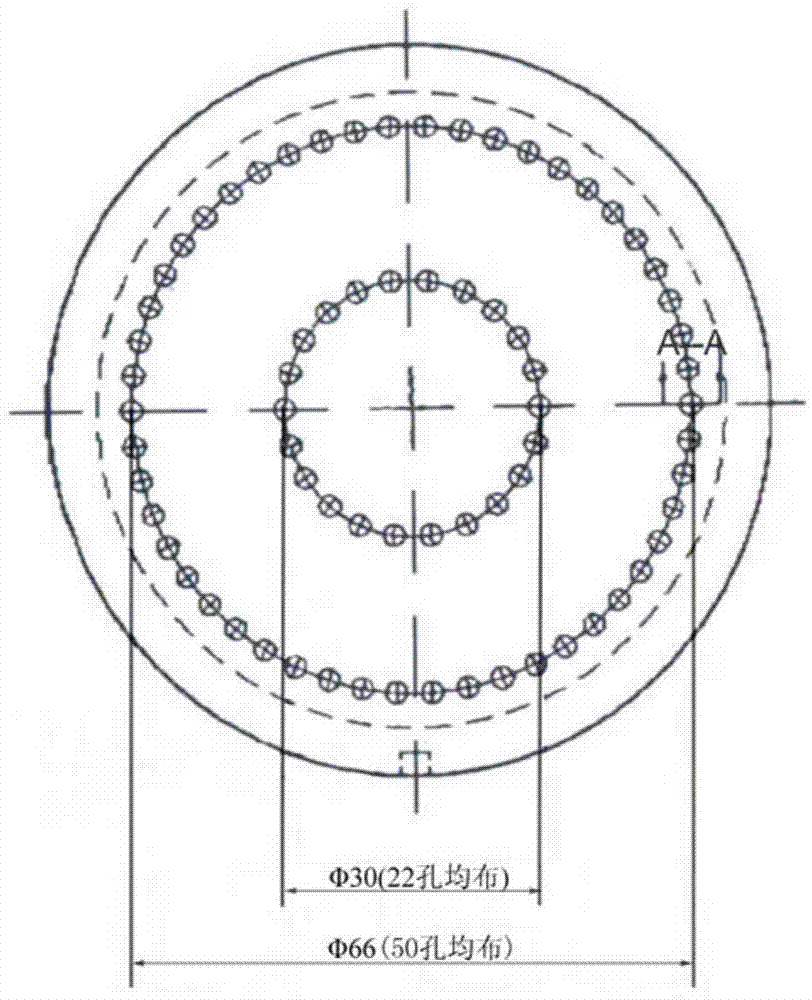

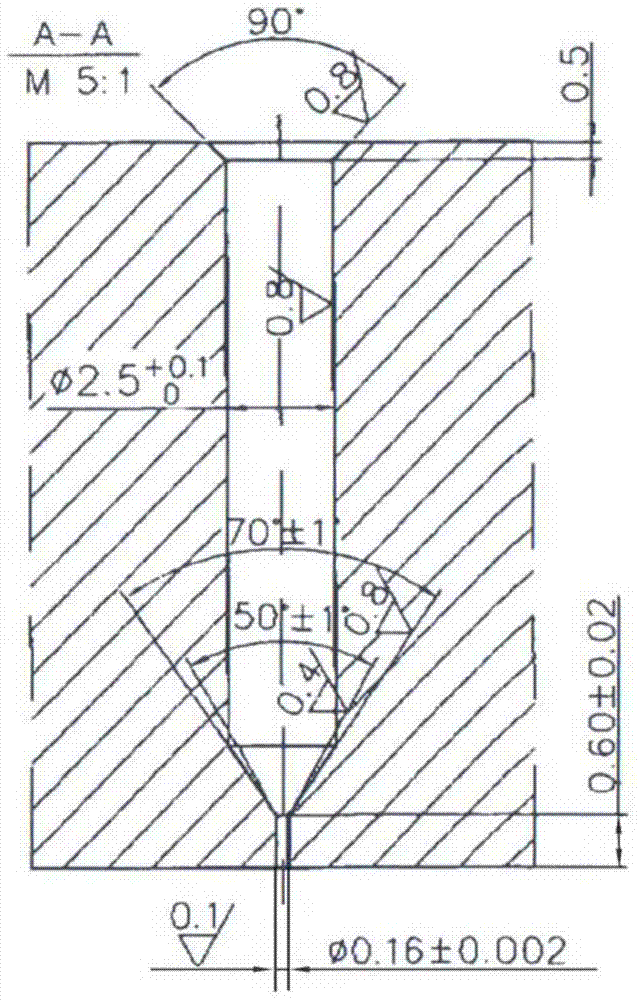

[0020] The spinneret structure that above-mentioned method adopts is as figure 2 As shown, the main body of the spinneret is circular, with two circles of evenly distributed spinneret holes...

Embodiment 2

[0023] Embodiment 2: POY spinning process provided by the present invention, its flow process is as figure 1 As shown, the molten polyethylene terephthalate is transported to the spinning box through the conveying and distribution pipeline, accurately metered by the metering pump and filtered by a multi-layer filter, and is sprayed out from the spinneret holes on the spinneret to form multi-strand monofilaments Thin stream, using advanced circular air blowing to cool the thin stream of monofilaments ejected from the spinneret holes to form solid monofilaments, which are clustered and oiled by oil nozzles, and finally wound and formed.

[0024] The multi-layer filter screen adopted in the method is a 100 / 50 mesh two-layer filter screen that is rolled together to a 10-layer filter screen.

[0025] The spinneret structure that above-mentioned method adopts is as figure 2 As shown, the main body of the spinneret is circular, with two circles of evenly distributed spinneret holes...

Embodiment 3

[0028] Embodiment 3: POY spinning process provided by the present invention, its flow process is as figure 1 As shown, the molten polyethylene terephthalate is transported to the spinning box through the conveying and distribution pipeline, accurately metered by the metering pump and filtered by a multi-layer filter, and is sprayed out from the spinneret holes on the spinneret to form multi-strand monofilaments Thin stream, using advanced circular air blowing to cool the thin stream of monofilaments ejected from the spinneret holes to form solid monofilaments, which are clustered and oiled by oil nozzles, and finally wound and formed.

[0029] The multi-layer filter screen adopted in the method is a 100 / 50 mesh two-layer filter screen that is rolled together to a 10-layer filter screen.

[0030] The spinneret structure that above-mentioned method adopts is as figure 2 As shown, the main body of the spinneret is circular, with two circles of evenly distributed spinneret holes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com