Construction method for impact holing of filling pile in tidal environment

A technology of impact hole forming and cast-in-place pile, which is applied to sheet pile walls, foundation structure engineering, construction, etc., which can solve problems such as low efficiency, slow construction speed, and difficulty in ensuring construction quality, so as to improve the process, increase efficiency, and shorten construction The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The tidal environment impact hole-forming cast-in-situ pile construction method of the present invention comprises the following steps:

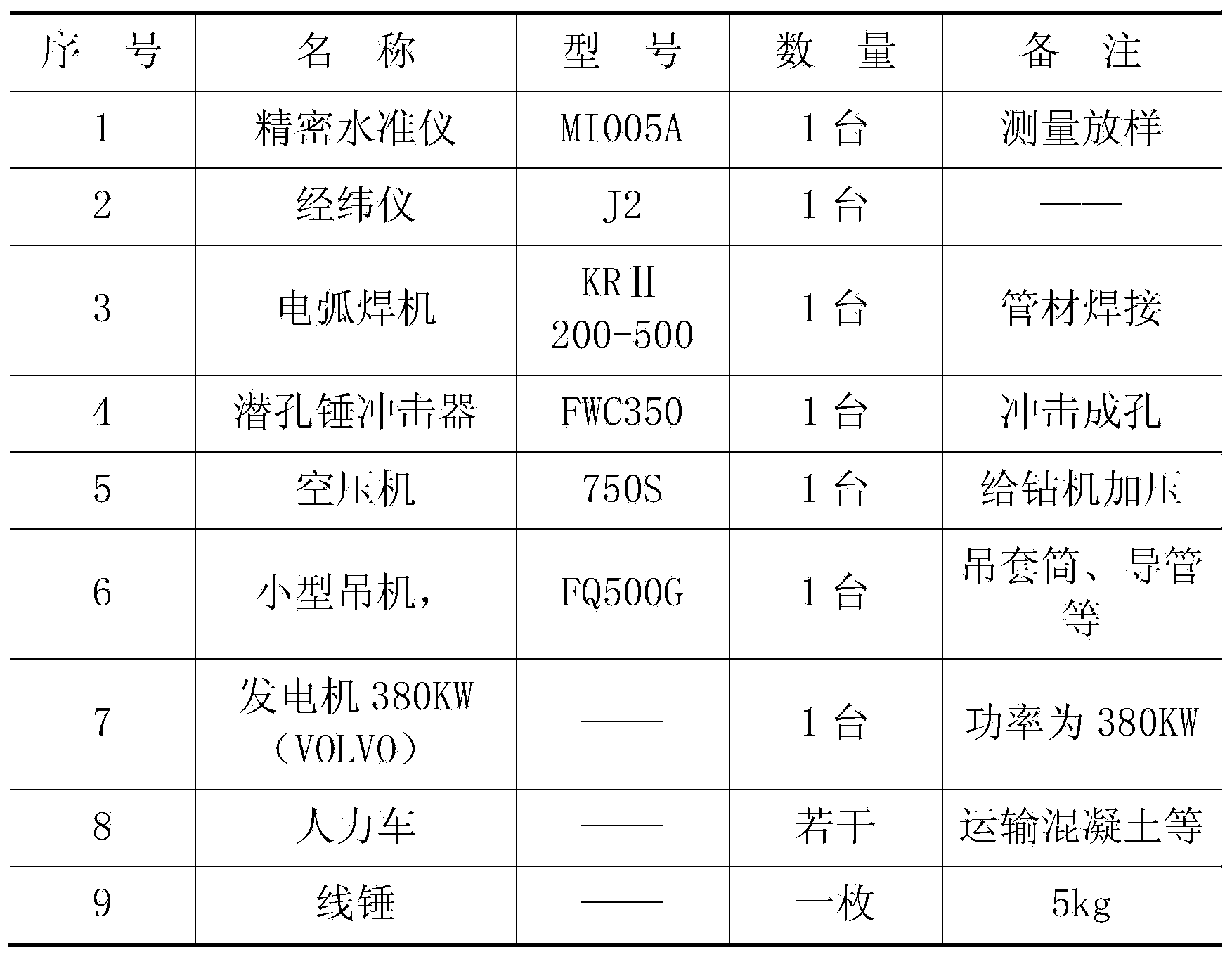

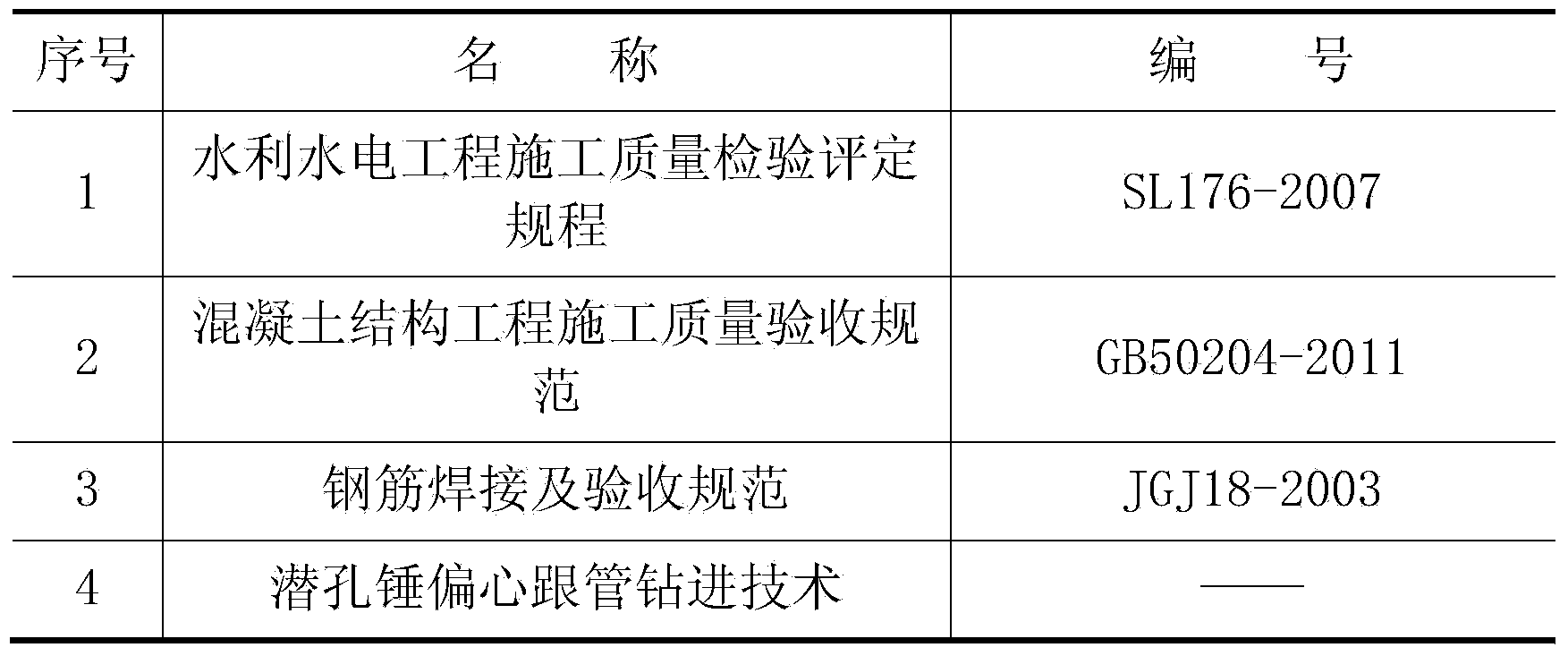

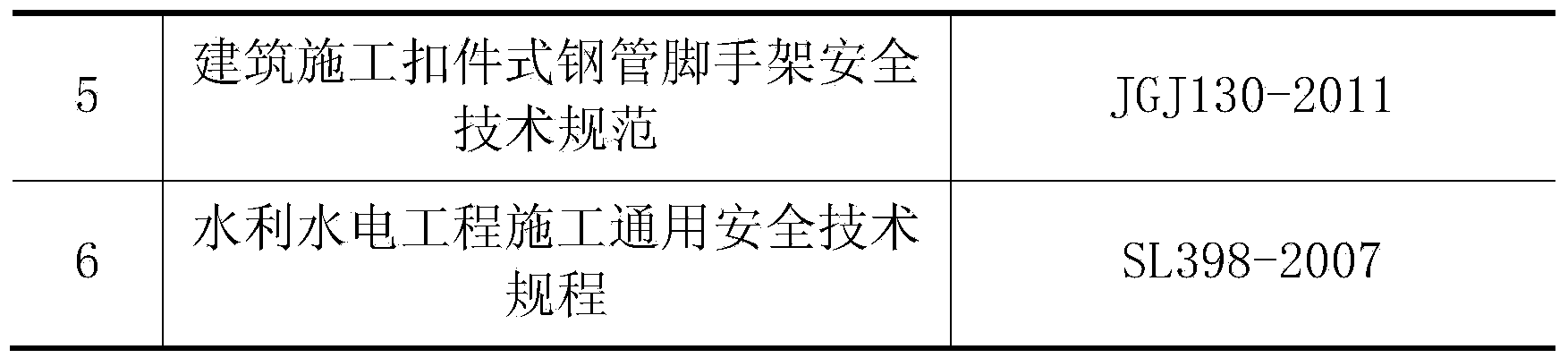

[0019] (a) Preparatory work: Construction personnel grasp the design intent and prepare for construction. Construction preparation includes familiarization with relevant technical design materials, construction drawings and technical standards and specifications for DTH hammer eccentric follower pipe drilling, etc. Before construction, relevant technical personnel shall investigate the hydrometeorology and tide level characteristics of the project location. Determine suitable working hours based on survey reports.

[0020] (b) Hole center positioning: The surveyor calculates the angle and sum of the survey control points to the project coordinates by using the relationship between the survey control points provided by the owner and the coordinates of the project based on the detailed observation and analysis of the drawings and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com