Integrated water heating floor block and heat conducting component thereof

A technology for heat-conducting components and floorboards, applied in the field of building decoration, can solve the problems of difficult implementation, poor reliability of heat storage and slow-release composite floor modules, and large distances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

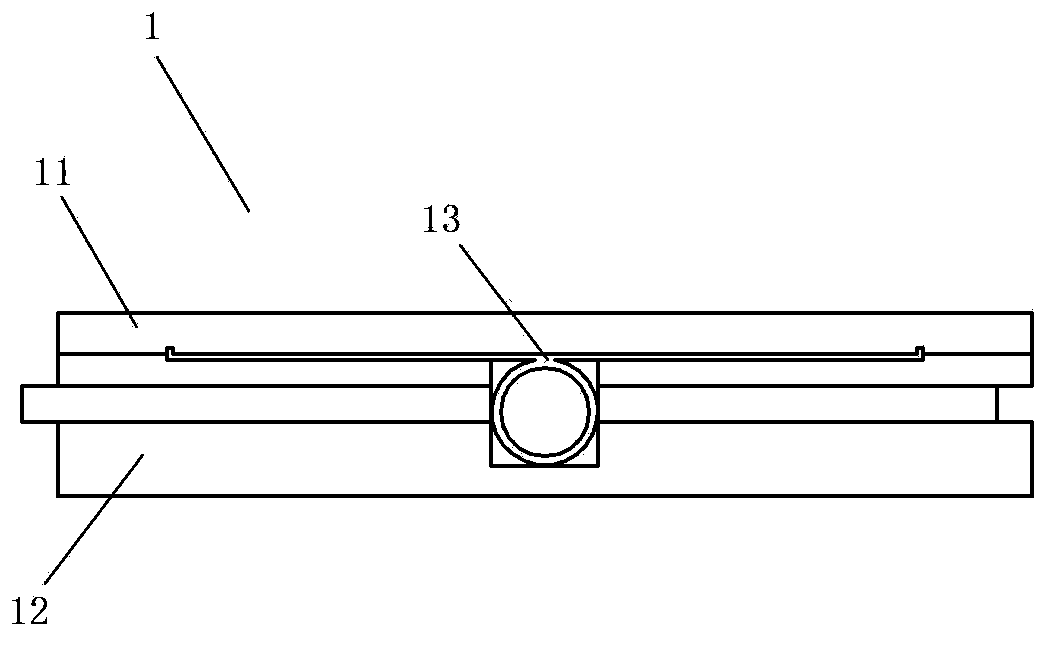

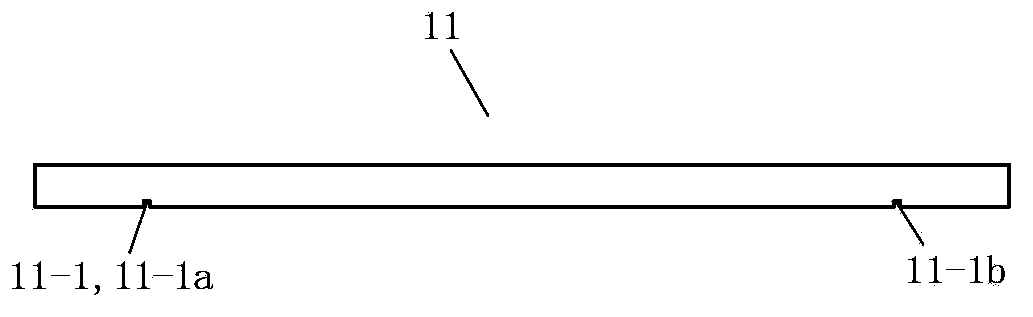

[0106] (Example 1, heat conducting member)

[0107] See Figure 9 and Figure 10, the heat conduction member 13 is an integral piece made of metal material, or is a glass fiber reinforced plastic profile, or an extruded profile made of plastic with a polymer material as the main component. In this embodiment, it is an aluminum alloy profile. The heat conducting member 13 includes a pipe part 13-1, a heat dissipation part 13-2 and a positioning part 13-3. The pipe part 13-1 is a linear pipe arranged along the front and back directions, and the inner wall of the pipe part 13-1 is sprayed with anti-corrosion paint; the heat dissipation part 13-2 is in the shape of a flat plate as a whole, and the heat dissipation part 13-2 is a direct heat dissipation part . The heat dissipation part 13-2 is connected to the duct part 13-1 from above. There are two positioning parts 13-3, which are respectively located on the left and right sides of the upper part of the heat dissipation part...

Embodiment 2

[0108] (Example 2, heat conducting member)

[0109] See Figure 11 , the rest of this embodiment is the same as that of Embodiment 1, and the heat conduction member 13 is still an aluminum alloy profile. to the through hole. Each heat soaking hole 13-4 is symmetrically arranged on the left and right sides of the heat dissipation part 13-2 with respect to the vertical plane passing through the axis of the pipe part 13-1 to form a left heat soaking hole group 13-4a and a right heat soaking hole Group 13-4b. The soaking holes 13-4 in each soaking hole group are arranged in different rows in the left and right directions, and the soaking holes 13-4 in each row are arranged at equal intervals along the front and rear directions, and the soaking holes in the same row The hole diameters of 13-4 are equal, and between the heat soaking holes 13-4 of adjacent rows, the hole diameter of the heat soaking holes 13-4 located in the left and right inner rows is larger than the hole diamet...

Embodiment 3

[0110] (Example 3, heat conducting member)

[0111] See Figure 13 to Figure 16 , the rest of this embodiment is the same as that of Embodiment 1, and the heat conduction member 13 is still an aluminum alloy profile. The difference is that the heat conduction member 13 of this embodiment is also equipped with a corresponding plug 14 and the following different technical features .

[0112] See Figure 18 and Figure 19 The heat dissipation part 13-2 of the heat conducting member 13 is divided into two heat dissipation parts, which are respectively located on the left and right sides of the pipe part 13-1. The structural shapes of the two heat dissipation parts are the same, and the two heat dissipation parts are divided into a left heat dissipation part 13-2a and a right heat dissipation part 13-2b according to their left and right positions. The two heat dissipation parts are both in the shape of a square tube, and the two heat dissipation parts are heat-gathering and hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com