Polymer PTC element with excellent weather resistance and its manufacturing method

A technology of PTC components and polymers, applied in the direction of resistors with positive temperature coefficients, resistor shells/packaging shells/potting, etc., can solve the problems of product reliability decline, poor weather resistance, easy aging, etc., to slow down aging speed, enhanced stability and reliability, and improved weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

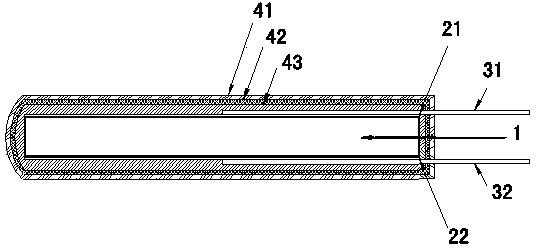

[0033] The present invention is further described below by accompanying drawing of description:

[0034] A PPTC element with excellent weather resistance, comprising a polymer PTC core material 1 and metal foils 21, 22 attached to both surfaces of the core material, lead-out electrodes 31, 32 welded on the outer surfaces of the metal foils 21, 22, The surfaces of the metal foils 21 and 22 are bumpy and protruding rough surfaces, wherein the outer side of the PPTC element is also coated with an insulating layer, and the insulating layer is a functional insulating layer composed of a three-layer structure, which are respectively: Photoaging layer 41 , anti-oxidation layer 42 and moisture-proof layer 43 .

[0035] Wherein the PTC core material 1 comprises a high molecular polymer, one or more than one inorganic conductive filler or metal powder.

[0036] In this embodiment, the three-layer structure of the insulating layer is as follows from outside to inside: an anti-aging laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com