Basalt fiber felt-loaded aluminum oxide defluorination and adsorption material and preparation method thereof

A technology of basalt fiber and adsorption materials, applied in chemical instruments and methods, aluminum silicate, inorganic chemistry, etc., can solve the problems of material center waste, difficult recovery of powder materials, high cost, etc., to achieve waste reduction, easy recycling, and saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

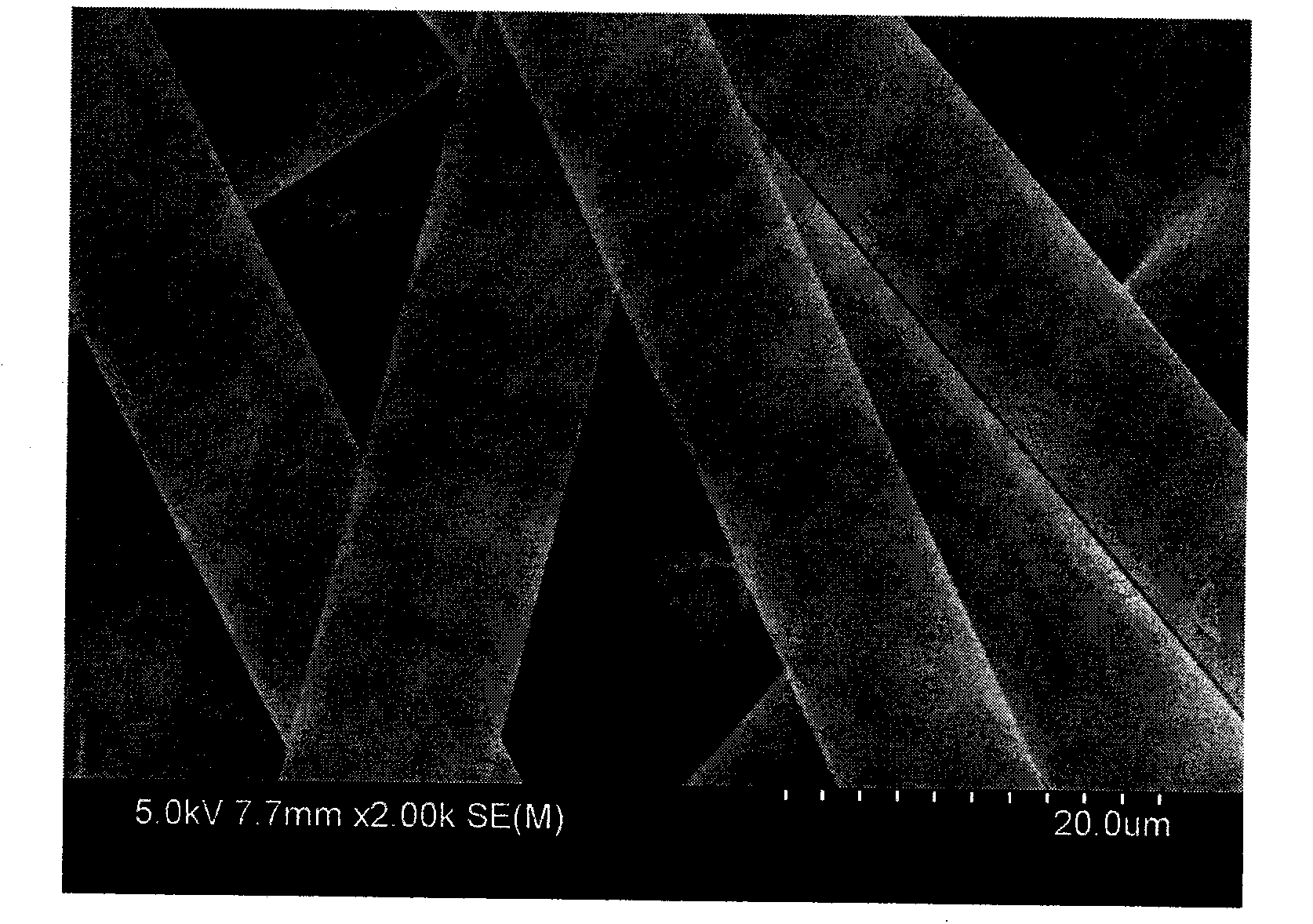

[0014] This embodiment provides a fluorine removal adsorption material, which is alumina loaded on basalt fiber mat, and alumina is loaded on the basalt fiber mat as a carrier.

[0015] The preparation method of the basalt fiber felt-loaded alumina defluoridation adsorption material is as follows:

[0016] (1) Weigh a certain amount of aluminum chloride hexahydrate, add deionized water to dissolve, configure a 0.6mol / L aluminum chloride solution, stir at a constant temperature at 50°C, and add it to the mixed solution at a rate of 1 drop per minute Add ammonia water dropwise until pH = 8, and boehmite gel has reacted at this time;

[0017] (2) Boehmite gel is suction filtered, and washed 5 times, to the filtrate is neutral, add a certain amount of deionized water, add the amount of deionized water and step (1) dissolve the used deionized water of aluminum chloride With the same amount, stir at a constant temperature of 80°C, and add a peptizer (1mol / L dilute nitric acid) drop...

Embodiment 2

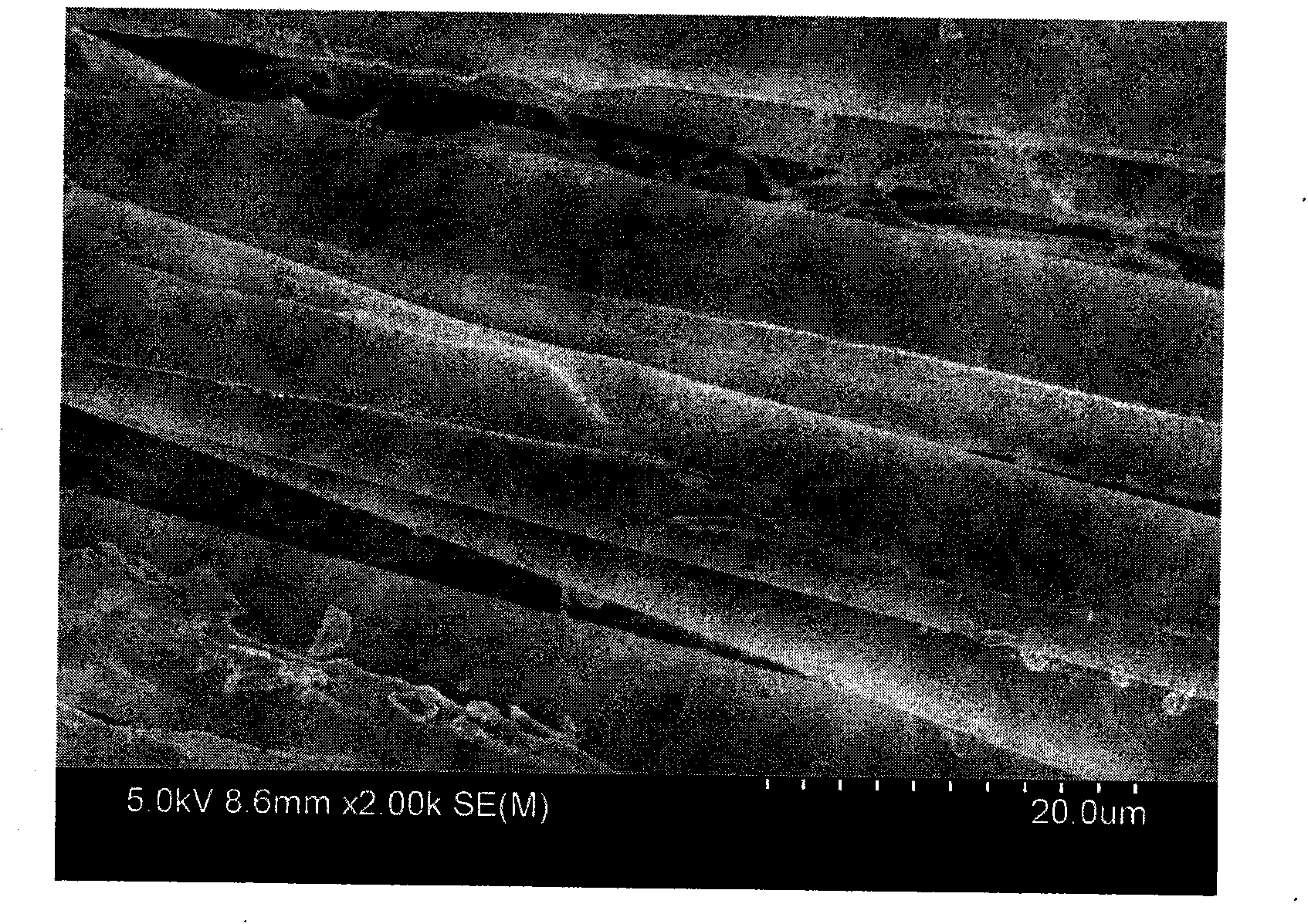

[0021] This embodiment provides a fluorine removal adsorption material, which is alumina loaded on basalt fiber mat, and alumina is loaded on the basalt fiber mat as a carrier.

[0022] The preparation method of the basalt fiber felt-loaded alumina defluoridation adsorption material is as follows:

[0023] (1) Weigh a certain amount of aluminum chloride hexahydrate, add deionized water to dissolve it, configure it into a 1.0mol / L aluminum chloride solution, stir it at a constant temperature at 70°C, and add it to the mixed solution at a rate of 2 drops per minute Add ammonia water dropwise until pH = 8, at which time the boehmite gel has reacted;

[0024] (2) Boehmite gel is suction filtered, and washed 8 times, to the filtrate is neutral, add a certain amount of deionized water, add the amount of deionized water and step (1) dissolve the used deionized water of aluminum chloride With the same amount, stir at 85°C at constant temperature, and add peptizer (1mol / L dilute nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com