Synthetic method of continuously copolymerized semi-aromatic nylon

A semi-aromatic nylon and synthetic method technology, applied in the field of materials, can solve the problems of unfavorable environmental protection, high organic matter emission, high melting point, etc., and achieve the effects of saving costs, reducing organic matter emission, and increasing reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

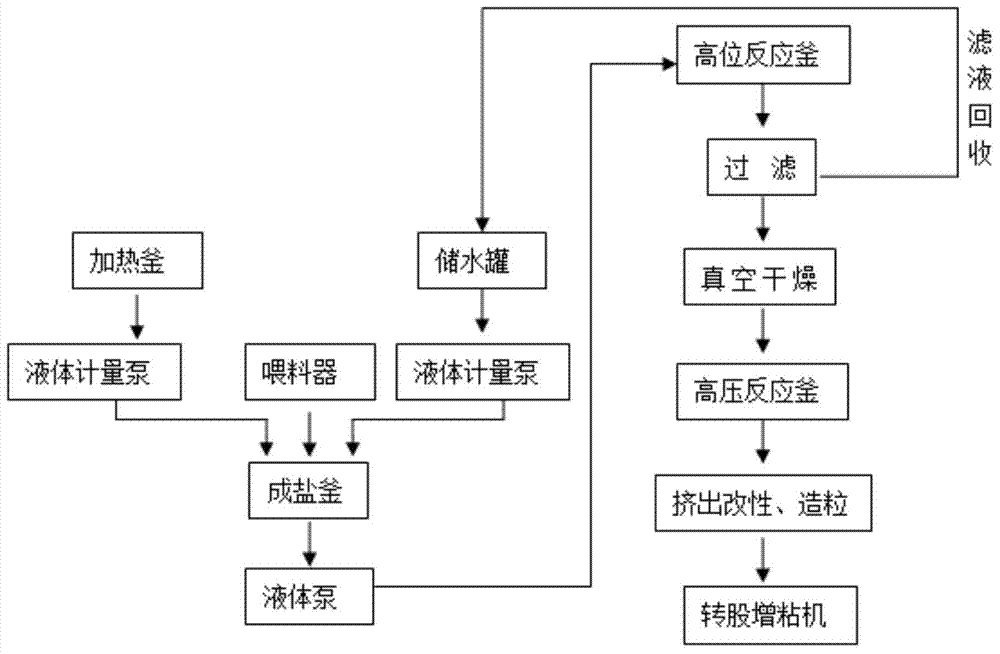

[0027] The steps of this embodiment are as follows figure 1 Shown: Add 70Kg of hexamethylenediamine into the heating kettle, raise the temperature to 48°C, stir and melt, after the hexamethylenediamine is completely melted, add it into the reaction kettle through the liquid metering pump, and start the reaction kettle to stir. 150Kg of deionized water is added into the salt-forming kettle through a liquid metering pump, 36.5Kg of adipic acid and 41.5Kg of terephthalic acid are added into the reaction kettle through a weight-loss feeder, and finally 250g of antioxidant (antioxidant Composed of phosphite antioxidants and hindered phenolic antioxidants in a weight ratio of 1:0.4), 250 grams of 2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)- 5-Chlorobenzotriazole, 120g sodium hypophosphite is added in the reactor through the manual feeding port. Under the condition of stirring, the temperature was slowly raised to 50° C. for 4 hours to obtain a clear nylon salt solution.

[0028] ...

Embodiment 2

[0033] The steps of this embodiment are as follows figure 1Shown: Add 60Kg of decanediamine into the heating kettle, raise the temperature to 48°C, stir and melt, after the decanediamine is completely melted, add it into the salt forming kettle through a liquid metering pump, and start the reaction kettle to stir. 160Kg of deionized water is added into the reactor through a liquid metering pump, 50Kg of sebacic acid and 41.5Kg of terephthalic acid are added into the reactor through a weight loss feeder, and finally 300g of antioxidant (antioxidant is made of Phosphate ester antioxidant and hindered phenol antioxidant (composed by weight ratio 1:0.5), 300g chain extender diaminodiphenylmethane, and 150Kg sodium hypophosphite were added to the reactor through the artificial feeding port. Under the condition of stirring, the temperature was slowly increased to 50° C. for 5 h to obtain a clear nylon salt solution.

[0034] Pour the nylon salt solution into the high-level reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com