Dye-based polarizing element and polarizing plate

A technology of polarizing element and alkoxy, applied in the direction of optical element, polarizing element, azo dye, etc., can solve the problem of discoloration of polarizer, and achieve the effect of good polarization characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

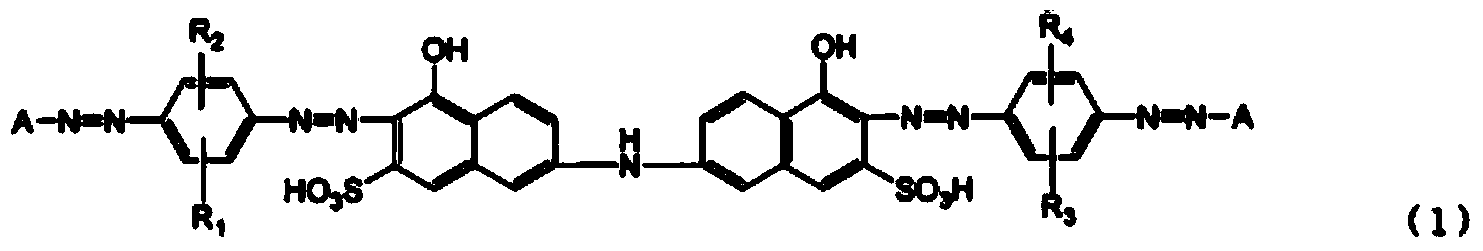

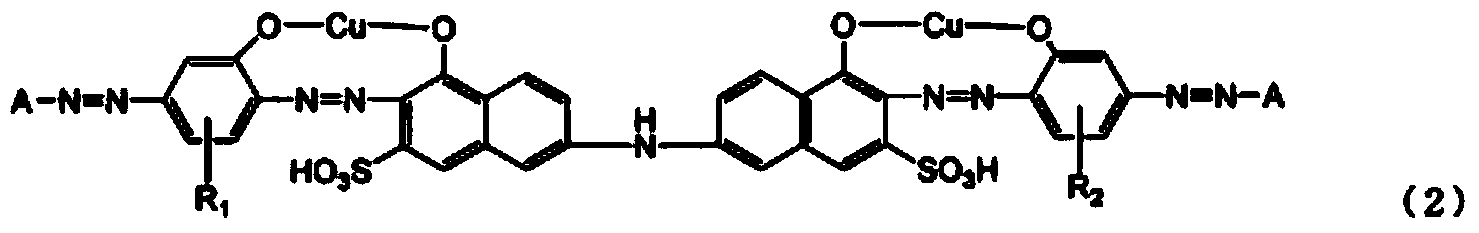

Image

Examples

Embodiment

[0074] The present invention will be described in more detail through examples below, but the present invention is not limited thereto. In addition, the evaluation of the transmittance and degree of polarization shown in an Example was performed as follows. In addition, "part" hereinafter means "part by weight".

[0075] A protective film is attached to both sides of the original polarizing film (plain film), and the transmittance when the obtained two polarizers are laminated in the same direction as their absorption axes is defined as the parallel transmittance Tp. The transmittance when the polarizing plates are laminated so that their absorption axes are perpendicular to each other is referred to as the orthogonal transmittance Tc.

[0076] Regarding the transmittance T, the spectral transmittance τλ was obtained at every predetermined wavelength interval dλ (here, 5 nm) in the wavelength range of 400 nm to 700 nm, and the transmittance T was calculated by the following f...

Synthetic example 1

[0085]

[0086] Dissolve 32.5 parts of 2-aminonaphthalene-4,8-disulfonic acid (common name: C acid) in 145 parts of water, add it to 140 parts of water containing 26 parts of 35% hydrochloric acid, at 15℃~20℃ Add 6.9 parts of sodium nitrite to carry out diazotization for 1 hour. Next, an aqueous solution consisting of 13.7 parts of 2-methoxy-5-methylaniline and 17.5 parts of 35% hydrochloric acid was added, and the coupling was carried out at 20°C for 4 hours while maintaining pH 3.0 to 3.5 with sodium acetate. , until less than 2-methoxy-5-methylaniline was confirmed in the spot test. Next, 21.4 parts of 35% hydrochloric acid were added to this aminoazo compound, 6.9 parts of sodium nitrite was added at 10°C, and diazotization was performed twice at 15°C to 20°C for 2 to 3 hours. Next, add it to an aqueous solution consisting of 31.5 parts of N,N-bis(1-hydroxy-3-sulfo-6-naphthyl)amine (common name: bis-J acid), 125 parts of water, and 11 parts of sodium carbonate. , a sod...

Embodiment 1

[0088]

[0089] A polyvinyl alcohol-based resin film (VF series manufactured by Kuraray Co., Ltd.) having a saponification degree of 99% or more and a film thickness of 75 μm was immersed in warm water at 40° C. for 2 minutes to perform swelling treatment. The membrane after the swelling treatment was immersed in a 45° C. aqueous solution containing 0.05% by weight of a dye represented by Compound 2 and 0.1% by weight of sodium tripolyphosphate to adsorb the dye. The dye-adsorbed membrane was washed with water, and after washing, boric acid treatment was performed for 1 minute with a 40° C. aqueous solution containing 2% by weight of boric acid. The film obtained by the boric acid treatment was stretched 5.0 times, and treated in an aqueous solution at 55° C. containing 3.0% by weight of boric acid for 5 minutes. Washing was performed with water at 30° C. for 15 seconds while maintaining the tense state of the film obtained by performing the boric acid treatment. The treate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com