Polyester fiber reinforced PVC (polyvinyl chloride) composite material with intermediate foaming layer

A composite material and polyester fiber technology, applied in the field of polyester fiber reinforced PVC composite material, polyester fiber reinforced PVC composite material and its preparation, can solve problems such as poor flatness, low surface strength, easy damage, etc., and achieve quality Lightweight, good bending resistance at low temperature, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

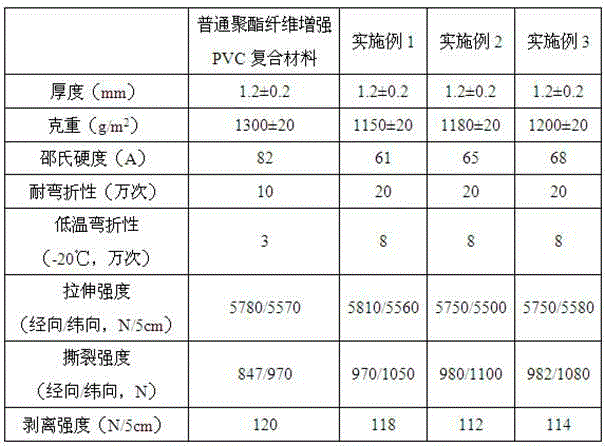

Embodiment 1

[0054] 1) Prepare PVC micro-foaming paste by stirring and grinding according to the following formula ratio and the requirements of each component.

[0055] 100 parts of PVC paste resin;

[0056] 60 parts of plasticizer;

[0057] 5 parts of organic modified kaolin;

[0058] Fumed silica 0.5 part;

[0059] 0.5 parts of heat-expandable microbeads;

[0060] 2 parts of liquid barium zinc stabilizer;

[0061] 3 parts adhesive;

[0062]The PVC paste resin is a composite system of microsuspension method paste resin (polymerization degree 1300±150) and emulsion method paste resin (polymerization degree 1450±200), with a mass ratio of 2:1;

[0063] Described plasticizer is the composite system of di-isooctyl terephthalate and epoxidized soybean oil, and the mass ratio is 11:1;

[0064] The organically modified kaolin is coal-based calcined kaolin modified with 1.5% aluminum-titanium composite coupling agent with a particle size greater than 3000 mesh.

[0065] The specific surfa...

Embodiment 2

[0095] 1) Prepare PVC micro-foaming paste by stirring and grinding according to the following formula ratio and the requirements of each component.

[0096] 100 parts of PVC paste resin;

[0097] 70 parts of plasticizer;

[0098] 8 parts of organic modified kaolin;

[0099] 2 parts of fumed silica;

[0100] 1.5 parts of heat-expandable microbeads;

[0101] 3 parts of liquid barium zinc stabilizer;

[0102] Adhesive 4 parts;

[0103] The PVC paste resin is a composite system of microsuspension method paste resin (polymerization degree 1300±150) and emulsion method paste resin (polymerization degree 1450±200), with a mass ratio of 3:1;

[0104] Described plasticizer is the composite system of di-isooctyl terephthalate and epoxidized soybean oil, and the mass proportion is 13:1;

[0105] The organically modified kaolin is coal-based calcined kaolin modified with 1.5% aluminum-titanium composite coupling agent with a particle size greater than 3000 mesh.

[0106] The specif...

Embodiment 3

[0137] 1) Prepare PVC micro-foaming paste by stirring and grinding according to the following formula ratio and the requirements of each component.

[0138] 100 parts of PVC paste resin;

[0139]80 parts of plasticizer;

[0140] 10 parts of organic modified kaolin;

[0141] 5 parts of fumed silicon dioxide;

[0142] 3 parts of heat-expandable microbeads;

[0143] 3 parts of liquid barium zinc stabilizer;

[0144] 5 parts of adhesive;

[0145] The PVC paste resin is a composite system of microsuspension method paste resin (polymerization degree 1300±150) and emulsion method paste resin (polymerization degree 1450±200), with a mass ratio of 4:1;

[0146] Described plasticizer is the composite system of di-isooctyl terephthalate and epoxidized soybean oil, and the mass proportion is 15:1;

[0147] The organically modified kaolin is coal-based calcined kaolin modified with 1.5% aluminum-titanium composite coupling agent with a particle size greater than 3000 mesh.

[0148] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com