Method for preparing micro/nanoscale carbon capsules

A micro-nano-scale, capsule technology, applied in the field of preparation of micro-nano-scale carbon capsules, can solve problems such as high cost, difficult control of carbon capsule particle size and capsule wall thickness, complex arc discharge process, etc., to achieve particle size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 50 mg micron-sized four-acicular ZnO particles and evenly disperse them on the quartz boat, the bottom area of the quartz boat is 5cm 2 Place the quartz boat that is dispersed with four needle-shaped ZnO particles in the middle of the quartz tube in the horizontal heating furnace, check the airtightness and fill with argon gas at 100ml / min for 30 minutes, and discharge the air; Slowly raise the temperature to 600°C at 2-3°C / min, stop filling with argon after 30 minutes of constant temperature; pass acetylene gas into the quartz tube at 30ml / min, keep the temperature, stop feeding acetylene after reacting for 60 minutes; then introduce argon gas to terminate the reaction, keep filling with argon and cool to room temperature with the furnace, and take out the obtained metal oxide / carbon layer composite.

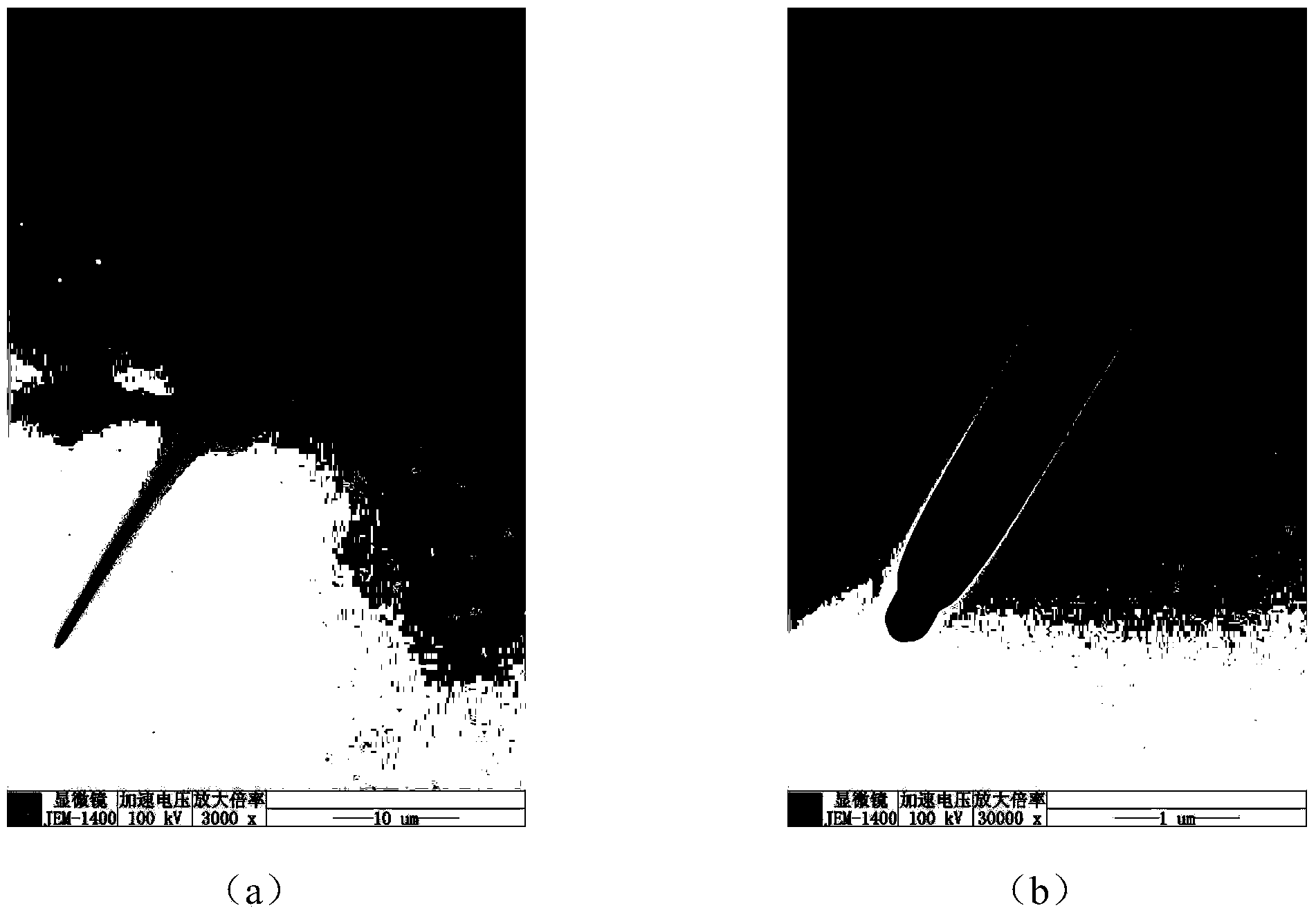

[0022] The microscopic morphology of metal oxide / carbon layer composites is as follows: figure 1 shown. in, figure 1 (a) is the overall picture, from figure 1...

Embodiment 2

[0024] Take 20mg of nanoscale quasi-spherical ZnO particles and evenly disperse them on the quartz boat, the area of the bottom of the quartz boat is 5cm 2 ; The quartz boat dispersed with nanoscale quasi-spherical ZnO particles is placed in the middle of the quartz tube in the horizontal heating furnace, checks the airtightness and fills with nitrogen gas at 30ml / min for 40 minutes, and the air is discharged; the horizontal heating furnace Slowly raise the temperature to 800°C at 1-3°C / min, stop feeding nitrogen after 50 minutes of constant temperature; pass acetylene gas into the quartz tube at 20ml / min, keep the temperature, stop feeding acetylene after reacting for 10 minutes; then introduce nitrogen Terminate the reaction, keep filling with nitrogen and cool to room temperature with the furnace, and take out the obtained metal oxide / carbon layer composite material.

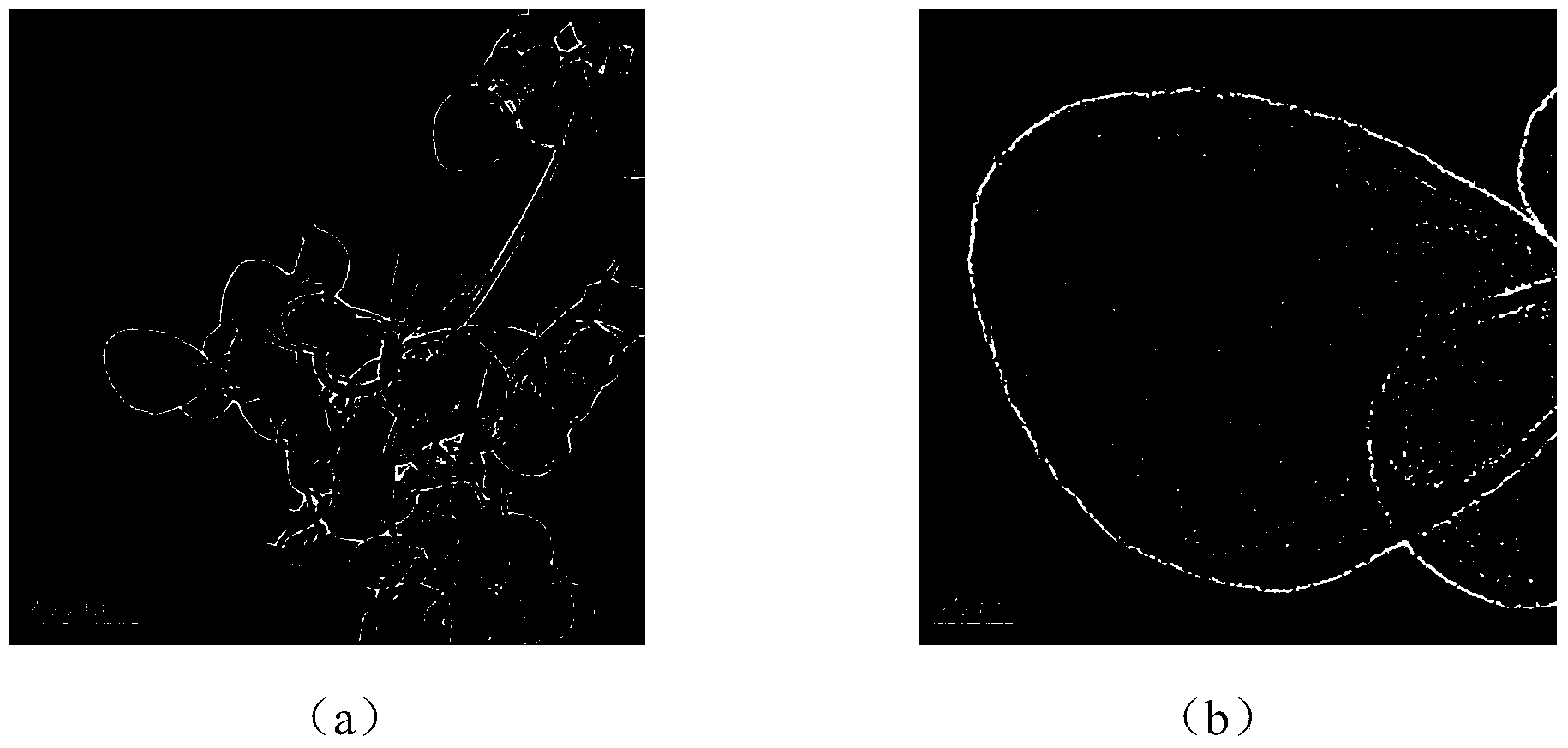

[0025] The metal oxide / carbon layer composite material was washed with HCl solution with a concentration...

Embodiment 3

[0027] Take 5mg of nanoscale rod-shaped ZnO particles and evenly disperse them on the quartz boat, the area of the bottom of the quartz boat is 5cm 2 Place the quartz boat dispersed with nanoscale rod-shaped ZnO particles in the middle of the quartz tube in the horizontal heating furnace, check the airtightness and fill with argon for 45 minutes at 40ml / min, and discharge the air;

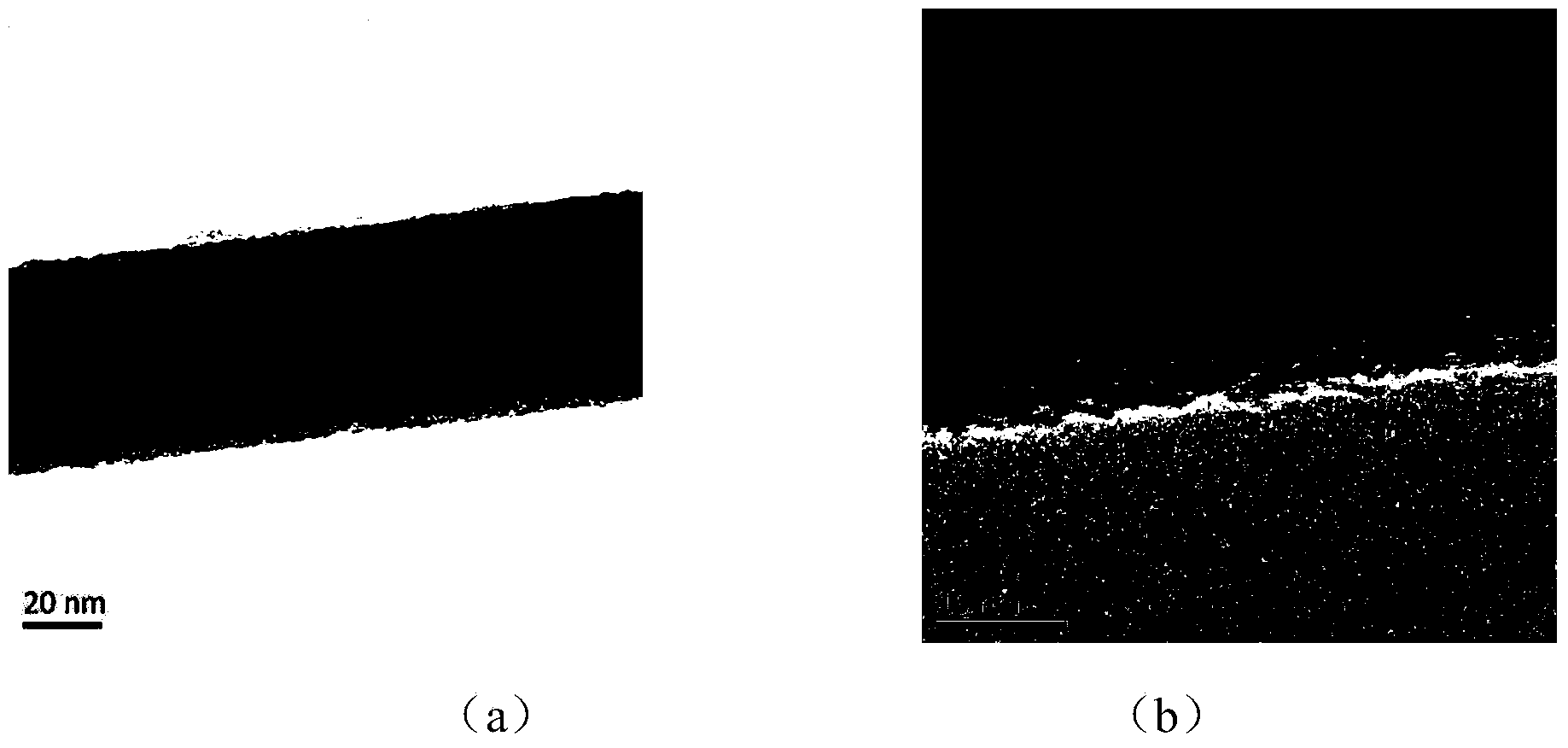

[0028] Slowly raise the temperature of the horizontal heating furnace to 400°C at 1-2°C / min, stop filling nitrogen after 60 minutes of constant temperature, pass acetylene gas into the quartz tube at 20ml / min, keep the temperature, stop feeding after 20 minutes of reaction Acetylene; then introduce nitrogen to terminate the reaction, keep filling with nitrogen and cool to room temperature with the furnace, and take out the obtained metal oxide / carbon layer composite. Its microscopic appearance is as image 3 shown. in, image 3 (a) is a low-magnification image, from image 3 The visible produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com