Concrete composite air entraining agent, its preparation and use methods

A technology of air-entraining agent and concrete, which is applied in the field of building materials, can solve the problems of poor solubility of air-entraining agent, poor bubble stability, strong bubble accumulation, etc., and achieve adjustable air-entraining volume, small negative impact on strength, and increased stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

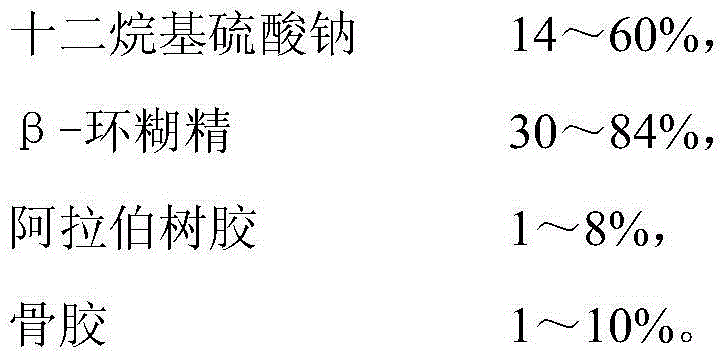

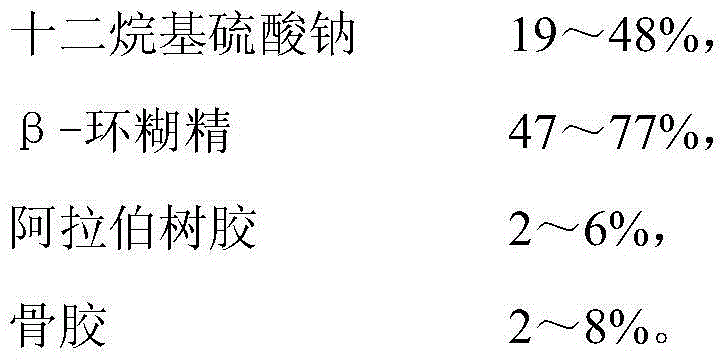

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, concrete composite air-entraining agent is formulated by sodium lauryl sulfate 48% (mass percentage, the same below), β-cyclodextrin 47%, gum arabic 2%, bone glue 3%, and benchmark concrete ( Compared with the concrete without adding the air-entraining agent, adding the air-entraining agent accounting for 0.004% of the cement mass can make the air content of the concrete reach 3%, the water reduction rate reaches 5.4%, and the bleeding rate decreases by 40% %, while the 3d, 7d, and 28d compressive strength ratios are all above 100%.

Embodiment 2

[0036] Example 2, the concrete composite air-entraining agent is prepared by 32% sodium lauryl sulfate, 57% beta-cyclodextrin, 3% gum arabic, and 8% bone glue. 0.012% of the air-entraining agent can make the air content of concrete reach 4.5%, the water reducing rate reach 6.5%, the bleeding rate reduce 70%, and the 3d, 7d, and 28d compressive strength ratios are all above 100%. Embodiment 3, the composite air-entraining agent for concrete is prepared by 31% sodium lauryl sulfate, 60% β-cyclodextrin, 6% gum arabic, and 3% bone glue. 0.016% of the air-entraining agent can make the air content of concrete reach 5.3%, the water reducing rate reach 7.6%, the bleeding rate reduce 64%, and the 3d, 7d, and 28d compressive strength ratios are all above 95%. Example 4, the composite air-entraining agent for concrete is prepared by 19% sodium lauryl sulfate, 77% beta-cyclodextrin, 2% gum arabic, and 2% bone glue. 0.02% of the air-entraining agent can make the air content of concrete re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com