A Composite Flame Retardant for Rigid Polyurethane Foam

A composite flame retardant and rigid polyurethane technology, which is applied in the field of polyurethane modification, can solve the problems of halogenated flame retardants and other problems, and achieve excellent flame retardant performance, price, non-toxic and pollution-free, good mechanical properties and heat insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

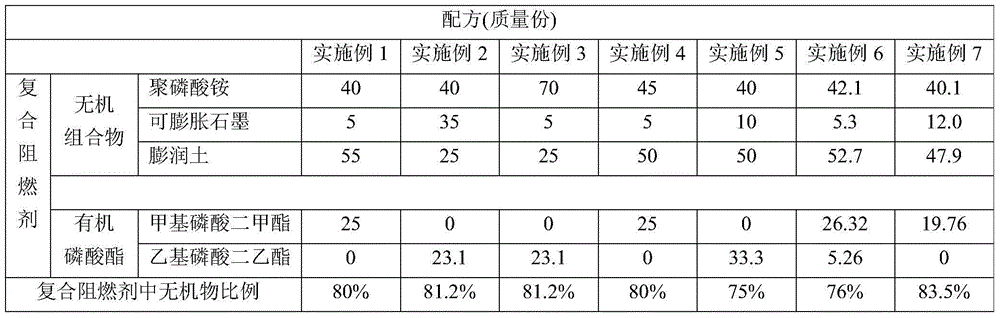

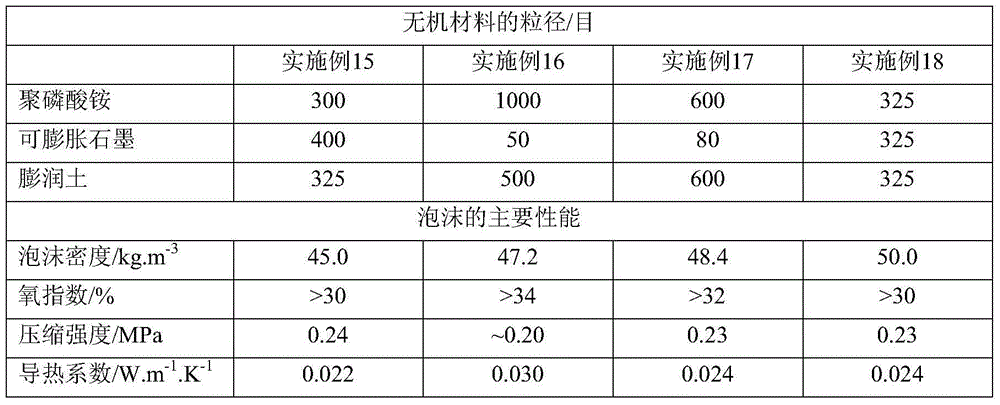

[0017] Embodiment 1~7 A kind of composite flame retardant preparation for rigid polyurethane foam

[0018] In Table 1, the particle size of ammonium polyphosphate is 500 mesh (about 28 microns), the particle size of expandable graphite is 80 mesh (180 microns), and the particle size of bentonite is 300 mesh (about 50 microns). Mix ammonium polyphosphate, expandable graphite, bentonite and organic phosphate according to the ratio listed in Table 1 to obtain the composite flame retardant of the present invention.

[0019] Table 1 A material formula table for a composite flame retardant for rigid polyurethane foam in Examples 1 to 7

[0020]

Embodiment 8~14

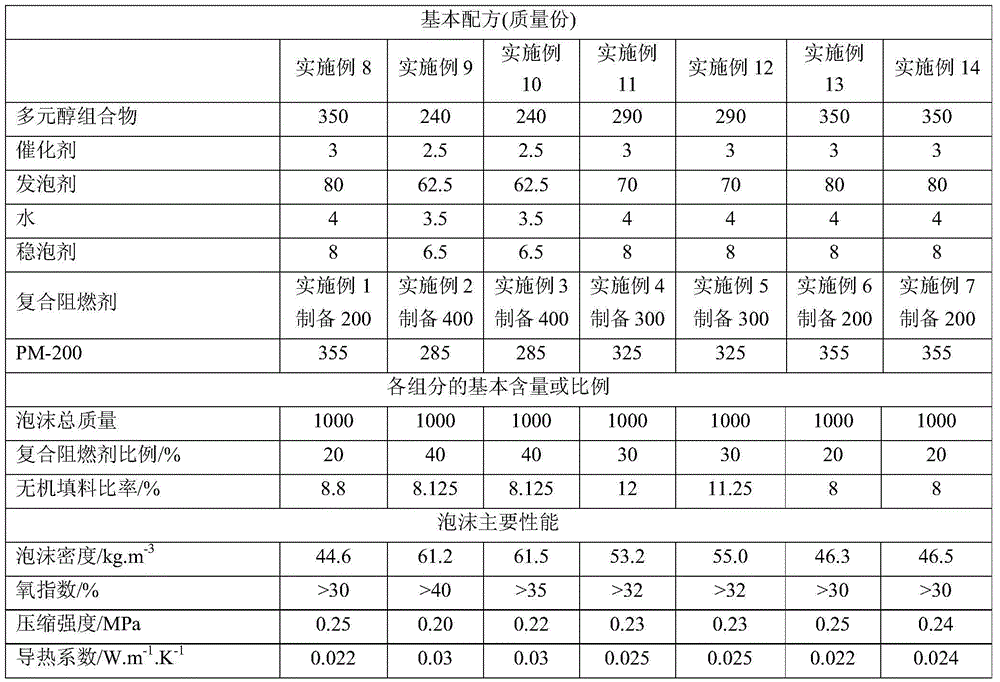

[0021] Embodiment 8~14 hard polyurethane foam preparation

[0022] According to the formula of each embodiment in table 2, at first the sucrose polyether polyol (polyether polyol 4450) of hydroxyl value 350mg KOH / g, the polyester polyol (rosin-phthalic anhydride) of hydroxyl value 430mg KOH / g Polyester polyol HF-800) and trifunctional polyether polyol (polyether polyol MN-400) with a hydroxyl value of 420 mg KOH / g are mixed together in a mass ratio of 4:1:2 to prepare polyol composition. Then add the catalyzer, and the catalyzer is made by mixing dibutyltin dilauryl and triethylenediamine in a mass ratio of 4:1; then will add foaming agent HCFC-141b, water and polysilicon with trade name AK-8803 The foam stabilizer of the oxyalkylene-oxyalkylene block, and fully stir and mix; then add the composite flame retardant, stir and mix evenly; (the order of adding the above-mentioned substances is not very strict, but it is good to mix evenly in the end) Add the measured polyisocyan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com