Method for producing cattle and sheep feed by taking shells as raw materials

A shell, cattle and sheep technology, applied in animal feed, animal feed, additional food elements, etc., can solve the problem of poor palatability of feed, and achieve the effect of increasing income, improving appetite, and comprehensive nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

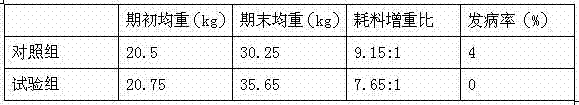

Examples

Embodiment 1

[0062] The following process steps can be used to prepare full-price feed for cattle and sheep by using shells as raw materials:

[0063] (1) Take 25 parts of shells, 25 parts of plant material, 10 parts of waste vegetable leaves, 6 parts of waste vegetable leaf concentrate juice, 8 parts of corn flour, 5 parts of edible mushroom bran, 5 parts of salt, 3 parts of rice bran, 2 parts of soybean meal part, 1 part of molasses, 0.1 part of fermented bacteria and 0.1 part of trace elements; one or more mixtures of the plant material corn stalk, fresh grass and mulberry branches; the composition of the trace elements and The parts by weight of each component: 2 parts of ferrous sulfate, 1 part of zinc sulfate, 2 parts of copper sulfate, 1 part of manganese sulfate, and 0.5 part of boric acid; the fermentation strains are Candida, Bacillus subtilis, photosynthetic Bacteria, cellulase, lactic acid bacteria, Streptococcus faecalis and EM bacteria, the weight ratio of which is 1:1:1:1:1:...

Embodiment 2

[0077] The following process steps can be used to prepare full-price feed for cattle and sheep by using shells as raw materials:

[0078] (1) Take 30 parts of shells, 28 parts of plant material, 12 parts of waste vegetable leaves, 8 parts of waste vegetable leaf concentrate juice, 9 parts of corn flour, 7 parts of edible mushroom bran, 5.5 parts of salt, 4 parts of rice bran, 3 parts of soybean meal parts, 1.5 parts of molasses, 0.3 parts of fermented bacteria and 0.2 parts of trace elements; one or more mixtures of the plant material corn stalk, fresh forage and mulberry branches; the composition of the trace elements and The parts by weight of each component: 3 parts of ferrous sulfate, 2 parts of zinc sulfate, 3 parts of copper sulfate, 2 parts of manganese sulfate, 1 part of boric acid; the fermentation strains are Candida, Bacillus subtilis, photosynthetic Bacteria, cellulase, lactic acid bacteria, Streptococcus faecalis and EM bacteria, the weight ratio of which is 1:1:1...

Embodiment 3

[0092] The following process steps can be used to prepare full-price feed for cattle and sheep by using shells as raw materials:

[0093] (1) Take 35 parts of shells, 30 parts of plant material, 15 parts of waste vegetable leaves, 10 parts of waste vegetable leaf concentrate juice, 10 parts of corn flour, 8 parts of edible mushroom bran, 6 parts of salt, 5 parts of rice bran, 5 parts of soybean meal part, 2 parts of molasses, 0.5 part of fermented bacteria and 0.3 part of trace elements; one or more mixtures in the described plant material corn stalk, fresh forage and mulberry branches; the composition of the described trace elements and The parts by weight of each component: 5 parts of ferrous sulfate, 3 parts of zinc sulfate, 4 parts of copper sulfate, 3 parts of manganese sulfate, and 1.5 parts of boric acid; the fermentation strains are Candida, Bacillus subtilis, photosynthetic Bacteria, cellulase, lactic acid bacteria, Streptococcus faecalis and EM bacteria, the weight r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com