A decarburization process suitable for high hydrocarbon and carbon dioxide rich gas

A carbon dioxide-enriched and dehydrocarbon technology, applied in the field of carbon dioxide dehydrocarbon purification, can solve problems such as wasting energy, and achieve the effects of reducing production costs, reducing losses, and saving production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

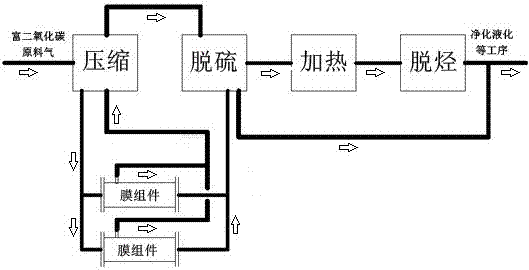

[0025] Such as figure 1 As shown, a dehydrocarbonization process suitable for high-hydrocarbon-rich carbon dioxide-rich gas uses refinery dry gas PSA tail gas as raw material gas, and the carbon dioxide content in the gas accounts for about 90%, and the remaining 10% is impurity gases such as hydrocarbons. The process is as follows step:

[0026] A. Pass the carbon dioxide-rich feed gas into the compressor, and after compression, pass the carbon dioxide-rich feed gas through two sets of polyimide membrane modules connected in parallel to separate the carbon dioxide-rich feed gas into two streams with a flow ratio of 1:1. One is permeate gas with hydrocarbon content less than 0.02%, and the other is permeate gas with hydrocarbon content up to 20%;

[0027] B. Desulfurize the permeate and permeate gas after re-compression;

[0028] C. Introduce the permeated gas after desulfurization treatment into the heater for heating;

[0029] D. Dehydrogenation of the permeated gas heat...

Embodiment 2

[0033] Such as figure 1 As shown, a dehydrocarbonization process suitable for high-hydrocarbon-rich carbon dioxide-rich gas uses refinery dry gas PSA tail gas as raw material gas, and the carbon dioxide content in the gas accounts for about 90%, and the remaining 10% is impurity gases such as hydrocarbons. The process is as follows step:

[0034] F. Pass the carbon dioxide-rich raw material gas into the compressor. After compression, the carbon dioxide-rich raw gas passes through two sets of polyimide membrane modules connected in parallel to separate the carbon dioxide-rich raw material gas into two gases with a flow ratio of 2:1. One is permeate gas with hydrocarbon content less than 0.02%, and the other is permeate gas with hydrocarbon content up to 30%;

[0035] G. Compress the permeate gas and the permeate gas separately and perform desulfurization treatment;

[0036] H. Introduce the permeated gas after desulfurization treatment into the heater for heating;

[0037] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com