Cotton fiber comprehensive treatment process

A comprehensive treatment and cotton fiber technology, which is applied in fiber treatment, biochemical fiber treatment, plant fiber, etc., can solve the problems of cellulose molecular chain oxidative breakage, poor hygroscopicity of cotton fiber, and difficulty in subsequent dyeing, achieving low water consumption, The effect of less heat energy consumption and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

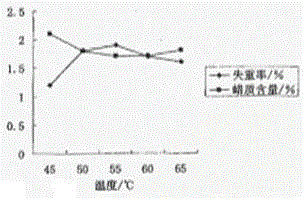

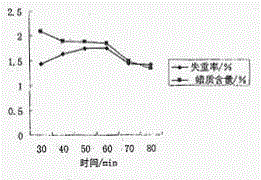

[0021] The cotton fiber comprehensive treatment process of the present invention is characterized in that: it comprises a pre-treatment process, a dyeing process, a softening process and a spinning process; the pre-treatment process comprises successively boiling the cotton fiber in water, soaking it with alkaline pectinase, and washing it with water. ; When the dyeing process is 60°C, the dye solution soaks the cotton fiber for 15 minutes, the NaCl solution soaks for 15 minutes, the temperature rises to 90°C, and at 90°C Na 2 CO 3 Soak in solution for 30 minutes, wash in water at 90°C for 10 minutes after dyeing, and dry; softening process, soak cotton fibers with softener solution, silicone dosage 9-11g / L, temperature 50-60°C, treatment time 50-70min , and then dried to a moisture content of 8-10%; the spinning process includes the following steps: dyed cotton is sequentially opened and cleaned, carded, and combed, white cotton is sequentially opened and cleaned, carded, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com