Cigarette paper with variable diffusion rate and pore structure and application thereof

A technology of cigarette paper and diffusivity, which is applied in the fields of special paper, paper, papermaking, etc., can solve the problems that the characterization method of cigarette paper diffusivity and cigarette paper pore structure has not been established, and reduce the CO emission of mainstream smoke, so as to be beneficial to industrialization Production and promotion application, high safety and practicality, obvious effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

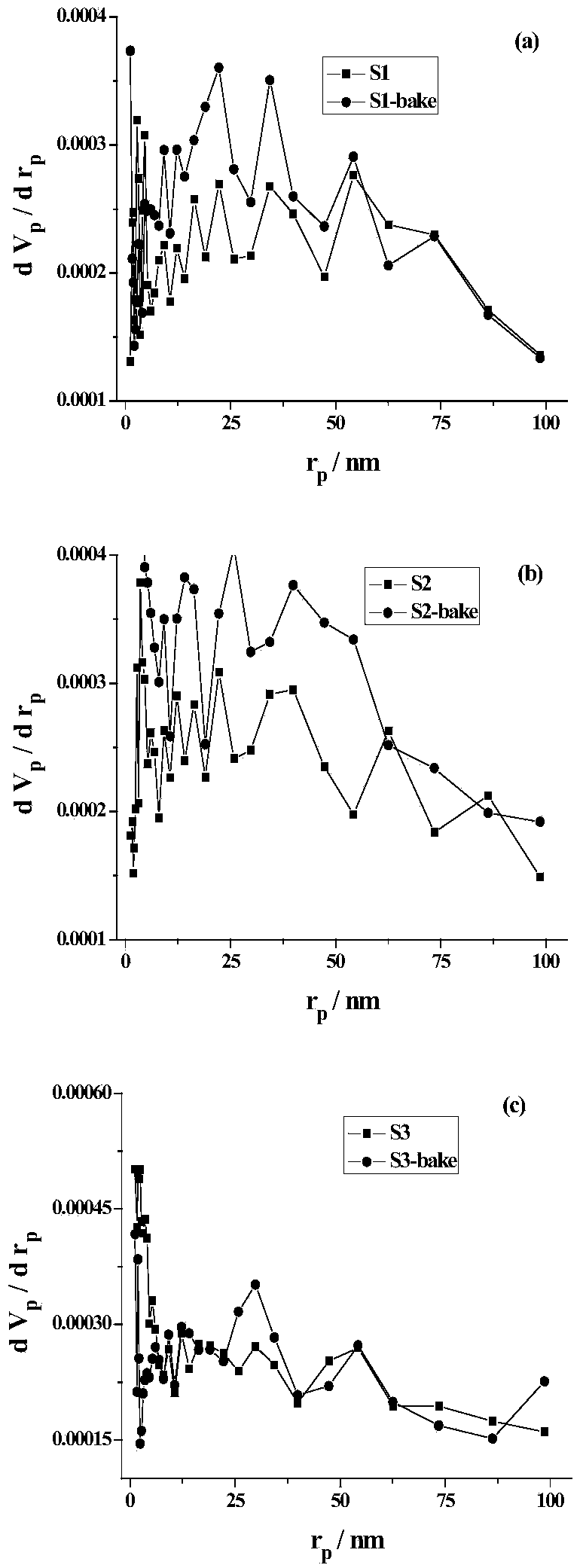

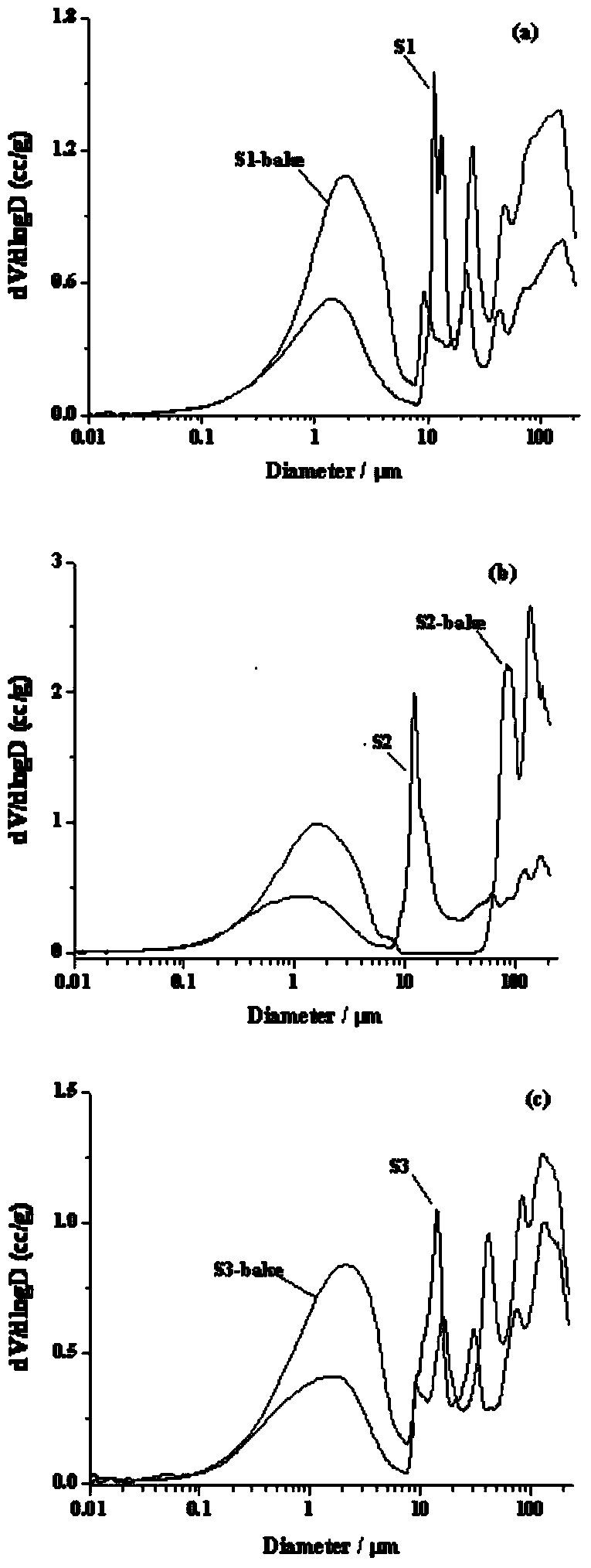

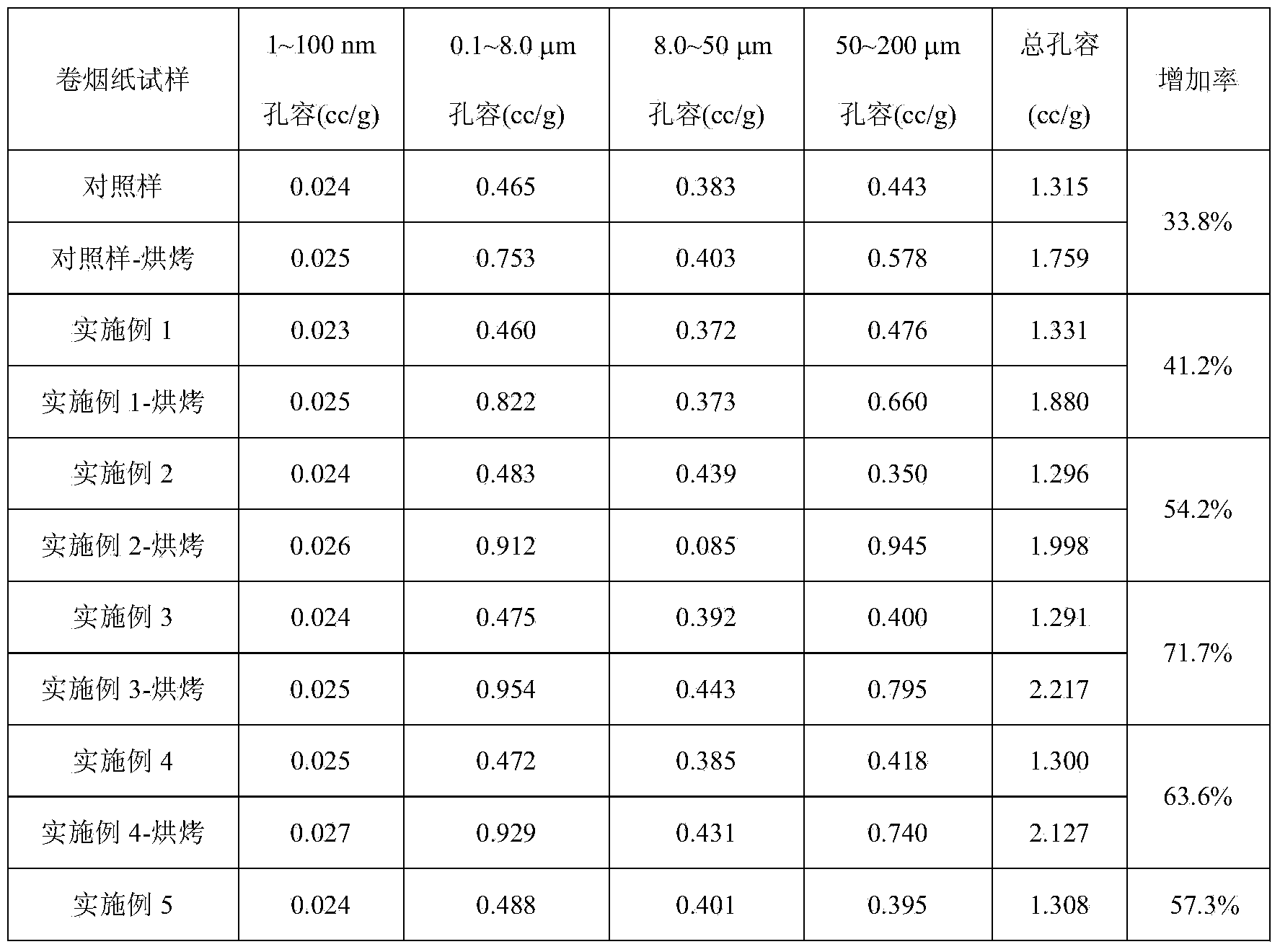

[0028] Dissolve 50 parts of potassium acetate, 25 parts of calcium lactate, 23 parts of calcium gluconate, and 2 parts of ferric citrate in 500 parts of water, stir well, and measure the pH of the solution to be 8.1. The prepared additive solution was evenly added to the cigarette paper in the sizing section of cigarette paper production through a metering rod film transfer sizing machine, and the production process and paper machine equipment parameters were adjusted to obtain a weight of 29g / m 2 , cigarette paper with an air permeability of 60CU (the amount of additives added in the cigarette paper is 0.95g / m 2 ). The paper diffusivity was tested by Sodim's automatic paper diffusivity meter. The test process for the change of the diffusivity of the test paper before and after heating is as follows: mark the test area when testing the diffusivity of the paper for the first time, heat the paper at 240-300°C for 20 minutes, and align the mark when testing the diffusivity of th...

Embodiment 2

[0030] Dissolve 85 parts of potassium bicarbonate, 8 parts of calcium acetate, 4 parts of calcium dihydrogen phosphate, and 3 parts of zinc lactate in 500 parts of water, stir well, and measure the pH of the solution to be 7.7. The prepared additive solution was evenly added to the cigarette paper in the sizing section of cigarette paper production through a metering rod film transfer sizing machine, and the production process and paper machine equipment parameters were adjusted to obtain a weight of 29g / m 2 , cigarette paper with an air permeability of 60CU (the amount of additives added in the cigarette paper is 0.97g / m 2 ). The paper diffusivity was tested by Sodim's automatic paper diffusivity meter. The test process for the change of the diffusivity of the test paper before and after heating is as follows: mark the test area when testing the diffusivity of the paper for the first time, heat the paper at 240-300°C for 20 minutes, and align the mark when testing the diffus...

Embodiment 3

[0032] Dissolve 95 parts of potassium lactate, 3 parts of tricalcium citrate, and 2 parts of zinc gluconate in 500 parts of water, stir well, and measure the pH of the solution to be 7.9. The prepared additive solution was evenly added to the cigarette paper in the sizing section of cigarette paper production through a metering rod film transfer sizing machine, and the production process and paper machine equipment parameters were adjusted to obtain a weight of 29g / m 2 , cigarette paper with an air permeability of 60CU (the amount of additives added in the cigarette paper is 1.06g / m 2 ). The paper diffusivity was tested by Sodim's automatic paper diffusivity meter. The test process for the change of the diffusivity of the test paper before and after heating is as follows: mark the test area when testing the diffusivity of the paper for the first time, heat the paper at 240-300°C for 20 minutes, and align the mark when testing the diffusivity of the paper after heating The ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com