Automatic seedling taking manipulator for plug seeding transplanter

A technology for plug seedlings and transplanting machines, applied in the directions of transplanting machinery, planting methods, applications, etc., can solve the problems of low transplanting efficiency, poor operation stability, affecting the quality of transplanting, etc., and achieves practical value for large production, Reliable performance and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings.

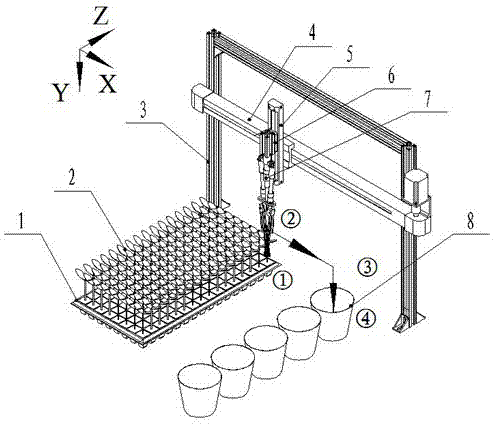

[0022] The seedling removal manipulator of the present invention includes a seedling removal mechanical arm and a seedling removal end effector 7. It is characterized in that: the seedling removal mechanical arm includes a linear module 4, a rodless cylinder 5 and a bracket 3;

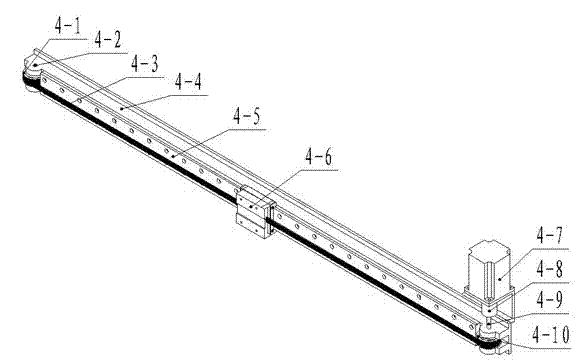

[0023] The linear module 4 is a synchronous belt structure, including a motor 4-7, a coupling 4-8, a shaft I 4-9, a shaft II 4-2, a timing belt 4-3, a driving pulley 4-10, and a driven Pulley 4-1, sliding block I 4-6, linear slide 4-5, bracket 4-4, etc. The motor 4-7 is vertically installed at one end of the horizontal bracket 4-4; one end of the coupling 4-8 is connected to the motor The output shaft of 4-7 is tightly connected, the other end of the coupling 4-8 is tightly connected with the rotating shaft I 4-9 of the driving pulley 4-10; the driving pulley 4-10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com