Grain drying system employing high-voltage electricity to accumulate heat, and drying method of grain drying system

A high-voltage electric heat storage and grain drying technology, which is applied in the direction of saving seeds through drying, can solve the problems of not being able to adapt to the development strategy of energy technology, the difficulty of achieving energy conservation and emission reduction goals, and excessive harmful gas emissions, so as to improve land quality. Utilization rate, reduction of operating costs, and the effect of saving construction land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention will be further described:

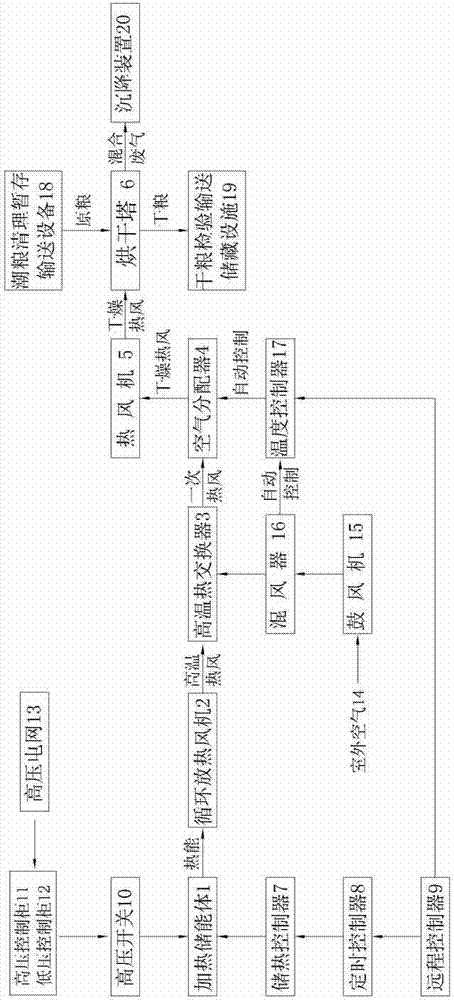

[0029] The principle of the present invention is to use the existing electrothermal energy storage technology to convert the idle, cheap low-peak electricity or discarded electricity (in wind power areas) at night into thermal energy and store it in the energy storage body, and the air heat exchange device and automatic temperature adjustment device will The thermal energy of 300-500°C in the energy storage body is converted into stable hot air of 40-180°C suitable for grain drying, and is continuously output to the heating section of the drying tower 6 through the hot air blower 5 for 24 hours to realize grain drying. Drying process.

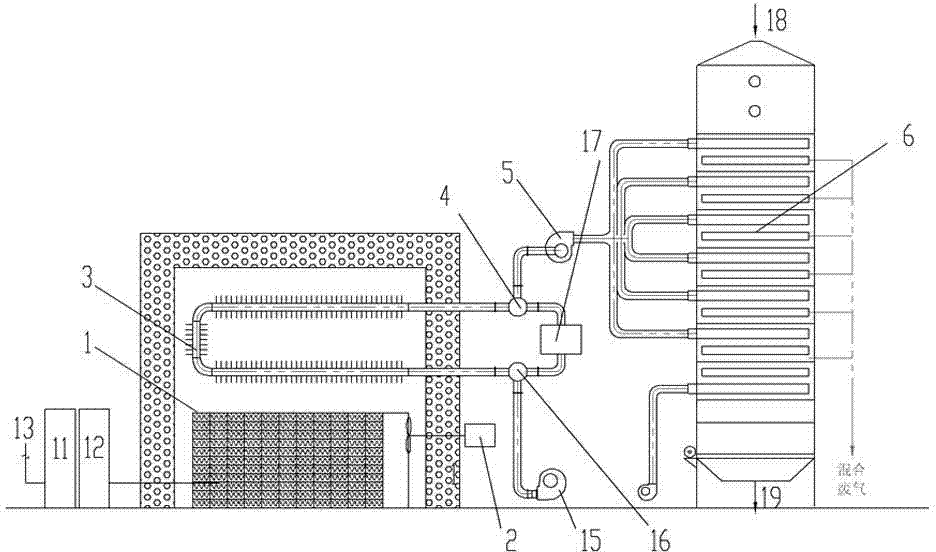

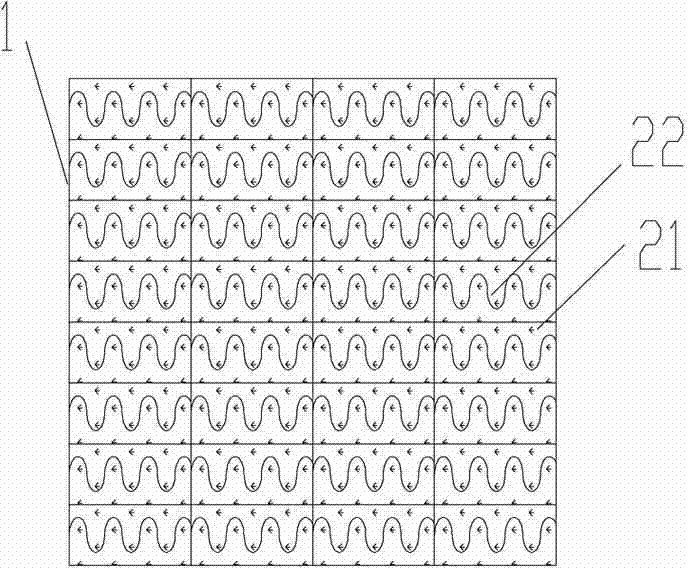

[0030] A grain drying system using high-voltage electric heat storage, such as Figures 1 to 3 As shown, the heating energy storage body 1, the circulating heat release fan 2, the high temperature heat exchanger 3, the air distributor 4, the hot air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com