Multi-station drilling machine

A drilling machine, multi-station technology, used in boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve problems such as unsuitable crystal drilling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

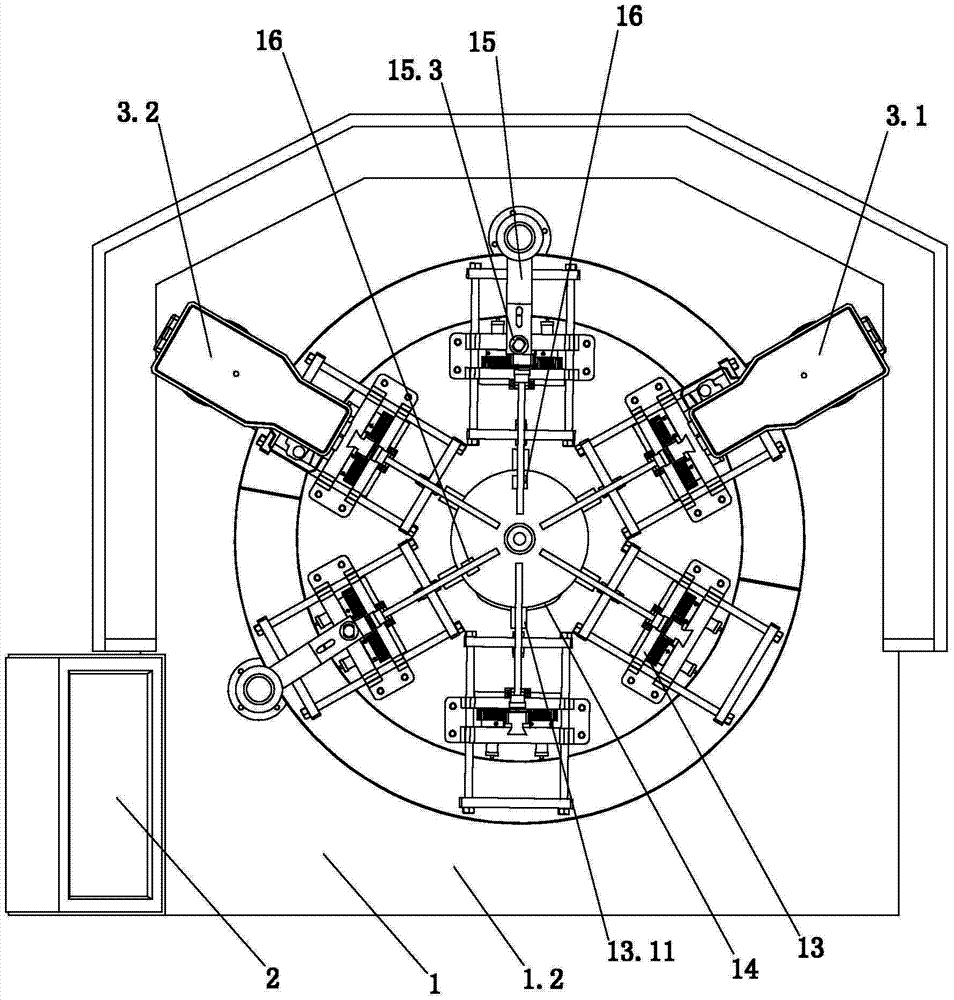

[0047] In the embodiment, assuming that the charging station is located at the forefront of the multi-station drilling machine, the first and second drilling mechanisms are respectively located at the oblique rear on the right side and obliquely rear on the left side of the charging station, and each 120 to the charging station 0 Angular distribution, the turntable rotates intermittently counterclockwise.

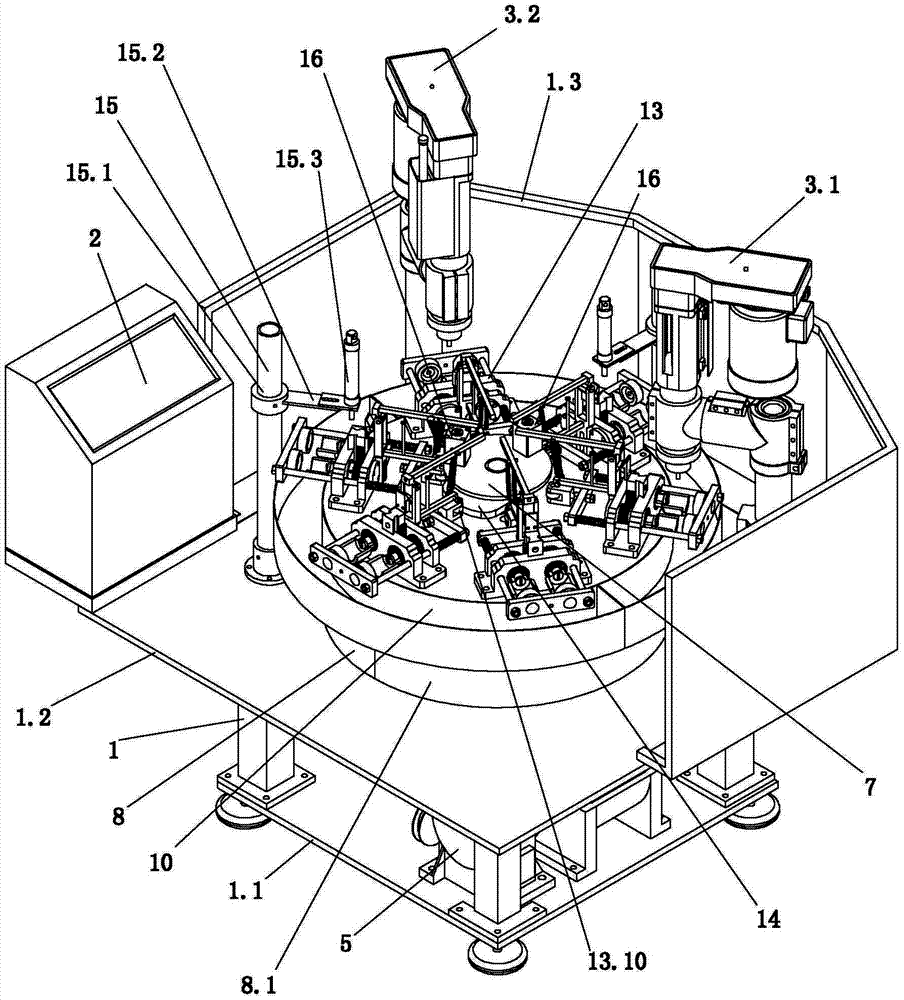

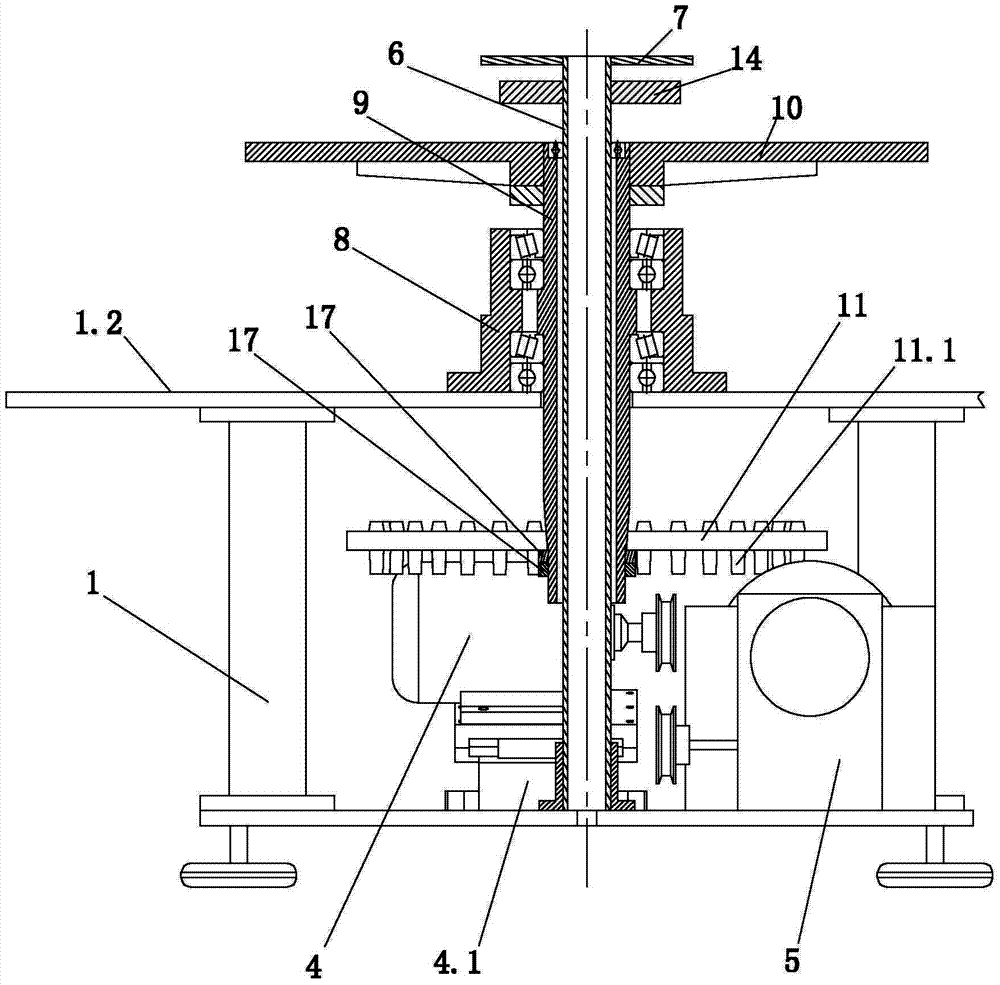

[0048] Such as figure 1 , figure 2 with image 3 Shown, the present invention comprises electric control box 2, frame 1, power mechanism and two into 120 0 The first and second drilling mechanisms 3.1, 3.2 arranged on the frame in angular distribution, and the air source system not shown in the figure. The air source system includes a connecting pipeline and a solenoid valve installed on the pipeline. The middle part of the upper deck 1.2 of the frame 1 is provided with a through hole, and the lower end of the vertical shaft 6 is fixedly connected with the frame 1 aft...

Embodiment 2

[0074] Such as figure 1 , image 3 with Figure 7 As shown, the difference between embodiment two and embodiment one is that embodiment two is also provided with two rack hitting cylinder mechanisms 15, and the rack hitting cylinder mechanism 15 includes hitting cylinder mounting columns 15.1, outer ends and The hitting cylinder installation rod 15.2 fixedly connected to the upper end of the hitting cylinder mounting column 15.1 and the hitting cylinder 15.3 fixed on the inner end of the hitting cylinder mounting rod 15.2; On the extension line between the center and the piston center of the two push cylinders 16, the lower end of the hitting cylinder mounting column 15.1 is firmly connected with the upper table 1.2, and the lower end 15.3.1 of the piston rod of the hitting cylinder 15.3 is located in the corresponding clamping Above the rear end of the rack 13.3 of the mechanism 13. As preferably, the hitting cylinder mounting rod 15.2 is adjustable to the hitting cylinder...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap