Method for preparing nano calcium carbonate quantum dot through microemulsion system

A nano-calcium carbonate and micro-emulsion technology is applied in the field of nano-materials to achieve the effects of stable performance, simple equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

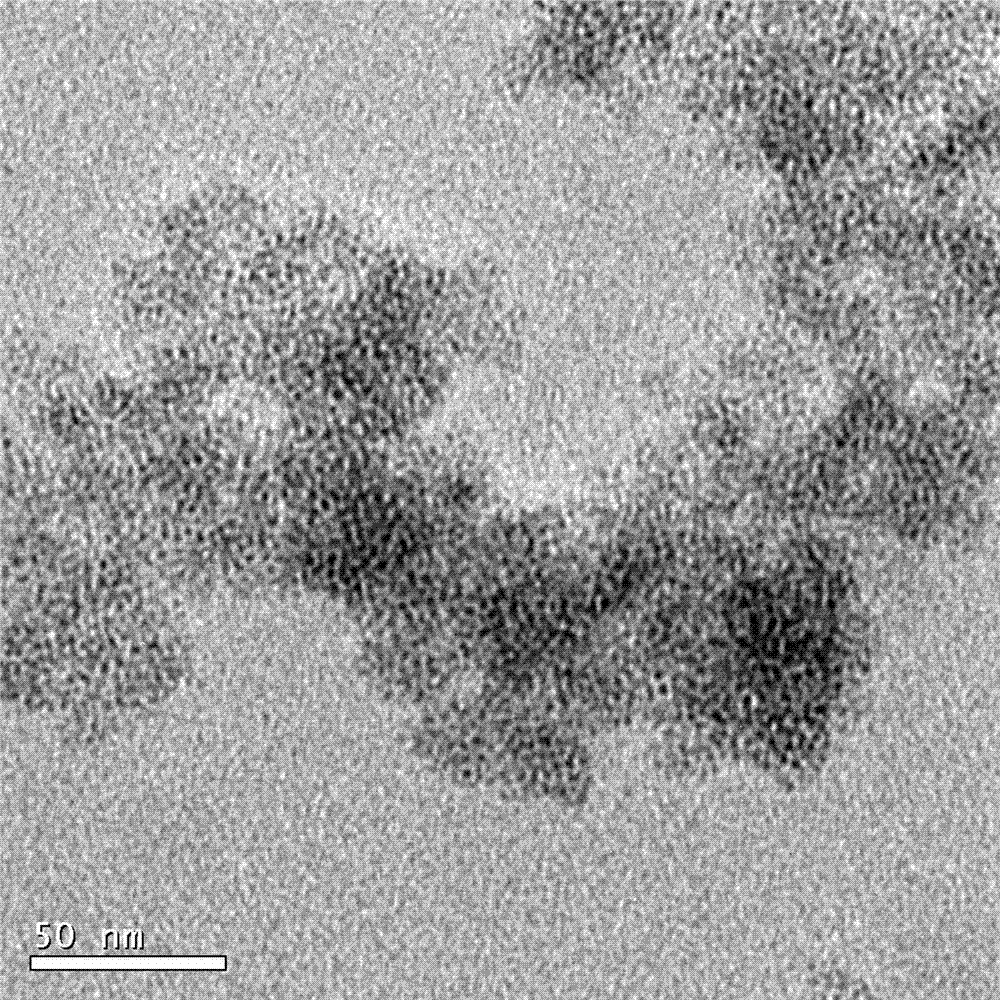

Image

Examples

Embodiment 1

[0027] (1) Preparation of microemulsion non-aqueous component system

[0028] At a temperature of 10°C, the non-water components in the system are mixed and stirred evenly according to the mass ratio of Tuwen-80 emulsifier: n-butanol co-emulsifier: toluene oil phase in the ratio of 2:3:5;

[0029] (2) Preparation of calcium chloride microemulsion

[0030] the Prepare Calcium Chloride Solution

[0031] Dissolve calcium chloride in the water phase and stir evenly to prepare an aqueous solution of calcium chloride with a concentration of 1.5M;

[0032] the Preparation of calcium chloride microemulsion

[0033] Put step (2) -- The prepared calcium chloride aqueous solution is mixed with the microemulsion non-aqueous component system prepared in step (1), and stirred evenly. The mass ratio of each component after mixing is emulsifier: co-emulsifier: toluene oil phase: calcium chloride is 2:3:5:0.4;

[0034] (3) Preparation of sodium carbonate microemulsion

[0035] Pr...

Embodiment 2

[0044] (1) Preparation of microemulsion non-aqueous component system

[0045] At a temperature of 20°C, each non-water component in the system is based on TW-80 emulsifier: n-butanol and n-octanol (n-butanol / n-octanol mass ratio is 8 / 2) co-emulsifier: toluene oil The mass ratio of the phases is 2:3:1.5 and mixed evenly;

[0046] (2) Preparation of calcium chloride microemulsion

[0047] the Prepare Calcium Chloride Solution

[0048] Dissolve calcium chloride in the water phase and stir evenly to prepare an aqueous solution of calcium chloride with a concentration of 1.0M;

[0049] the Preparation of calcium chloride microemulsion

[0050] Put step (2) -- The prepared calcium chloride aqueous solution is mixed with the microemulsion non-aqueous component system prepared in step (1), and stirred evenly. The mass ratio of each component after mixing is emulsifier: co-emulsifier: toluene oil phase: calcium chloride is 2:3:1.5:0.2;

[0051] (3) Preparation of sodium carb...

Embodiment 3

[0061] (1) Preparation of microemulsion non-aqueous component system

[0062] At a temperature of 30°C, each non-aqueous component in the system is based on emulsifier (Span-80 / Towen-60 / OP-10 / AEO-3 mass ratio is 1 / 2 / 2 / 1): assistant emulsification Agent (mass ratio of isohexanol / n-butanol is 1 / 9): the mass ratio of toluene oil phase is 2:2.5:4, mix and stir evenly;

[0063] (2) Preparation of calcium chloride microemulsion

[0064] the Prepare Calcium Chloride Solution

[0065] Dissolve calcium chloride in the water phase and stir evenly to prepare a calcium chloride aqueous solution with a concentration of 2.0M;

[0066] the Preparation of calcium chloride microemulsion

[0067] Put step (2) -- The prepared calcium chloride aqueous solution is mixed with the microemulsion non-aqueous component system prepared in step (1), and stirred evenly. The mass ratio of each component after mixing is emulsifier: co-emulsifier: toluene oil phase: calcium chloride is 2:2.5:4:0.35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com