Permeability-improving anti-fog glass and preparation method for same

A technology of anti-fog glass and glass flakes, which is applied in the field of nano-material preparation, can solve the problems of glass products such as poor wear resistance and heat resistance, many components, and large energy consumption, so as to improve hydrophilicity and mechanical properties, The effect of wide application prospect and good anti-fog performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

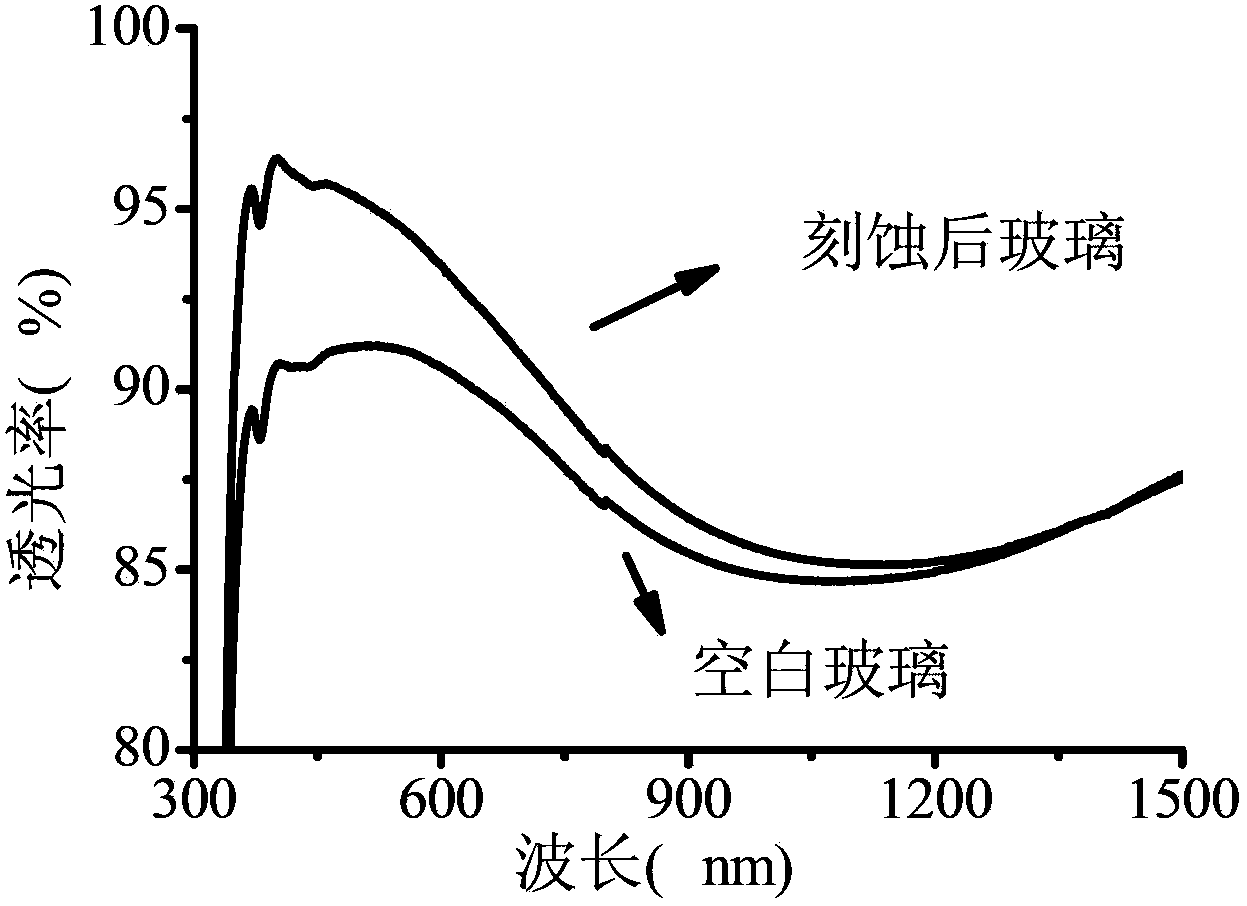

Embodiment 1

[0046] Add 30mL of fluorosilicic acid aqueous solution with a concentration of 0.75mol / L to a 500mL container with a polytetrafluoroethylene material as the inner liner, and wash the cleaned glass sheet (the size of the glass sheet is 2.5 cm (width) × 7.5 cm (length) × 0.1 cm (thickness)) placed on the four-legged support; put the glass piece together with the support into a container with polytetrafluoroethylene as the inner liner, and the glass piece is suspended horizontally in the container in the aqueous solution of fluorosilicic acid Above, cover the lid of the container, put the container with the lid into the hydrothermal kettle, cover the lid of the hydrothermal kettle and tighten it, in a sealed state, put the hydrothermal kettle into the constant temperature box, at a temperature of The glass sheet was etched at 15°C for 48 hours, and a layer of porous structure layer with a thickness of 52nm extending from the surface of the glass sheet to the inside of the glass sh...

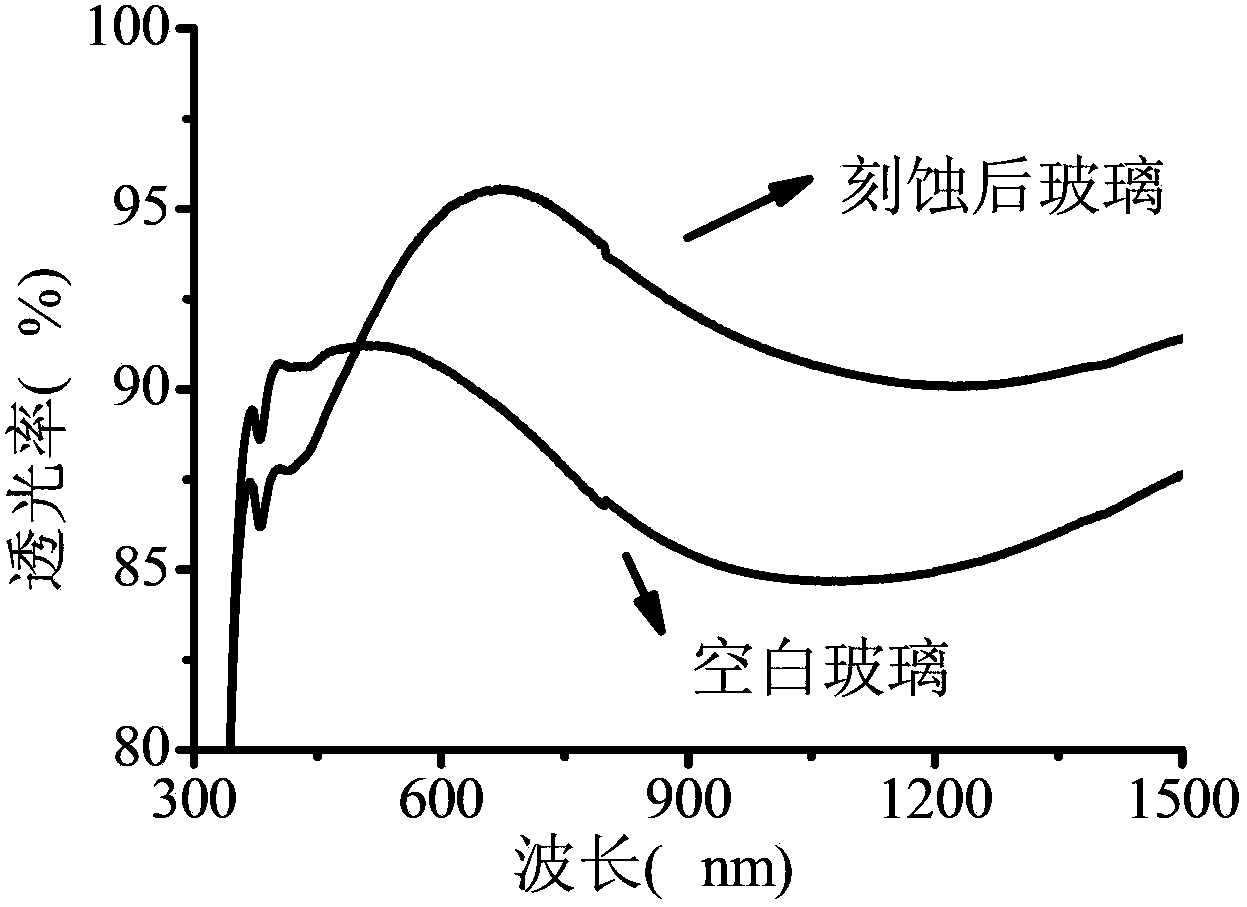

Embodiment 2

[0049] Add 30mL of fluorosilicic acid aqueous solution with a concentration of 1.50mol / L to a 500mL container with a polytetrafluoroethylene material as the inner liner, and wash the cleaned glass sheet (the size of the glass sheet is 2.5 cm (width) × 7.5 cm (length) × 0.1 cm (thickness)) placed on the four-legged support; put the glass piece together with the support into a container with polytetrafluoroethylene as the inner liner, and the glass piece is suspended horizontally in the container in the aqueous solution of fluorosilicic acid Above, cover the lid of the container, put the container with the lid into the hydrothermal kettle, cover the lid of the hydrothermal kettle and tighten it, in a sealed state, put the hydrothermal kettle into the constant temperature box, at a temperature of The glass sheet was etched at 15°C for 48 hours, and a layer of porous structure layer with a thickness of 76nm extending from the surface of the glass sheet to the inside of the glass sh...

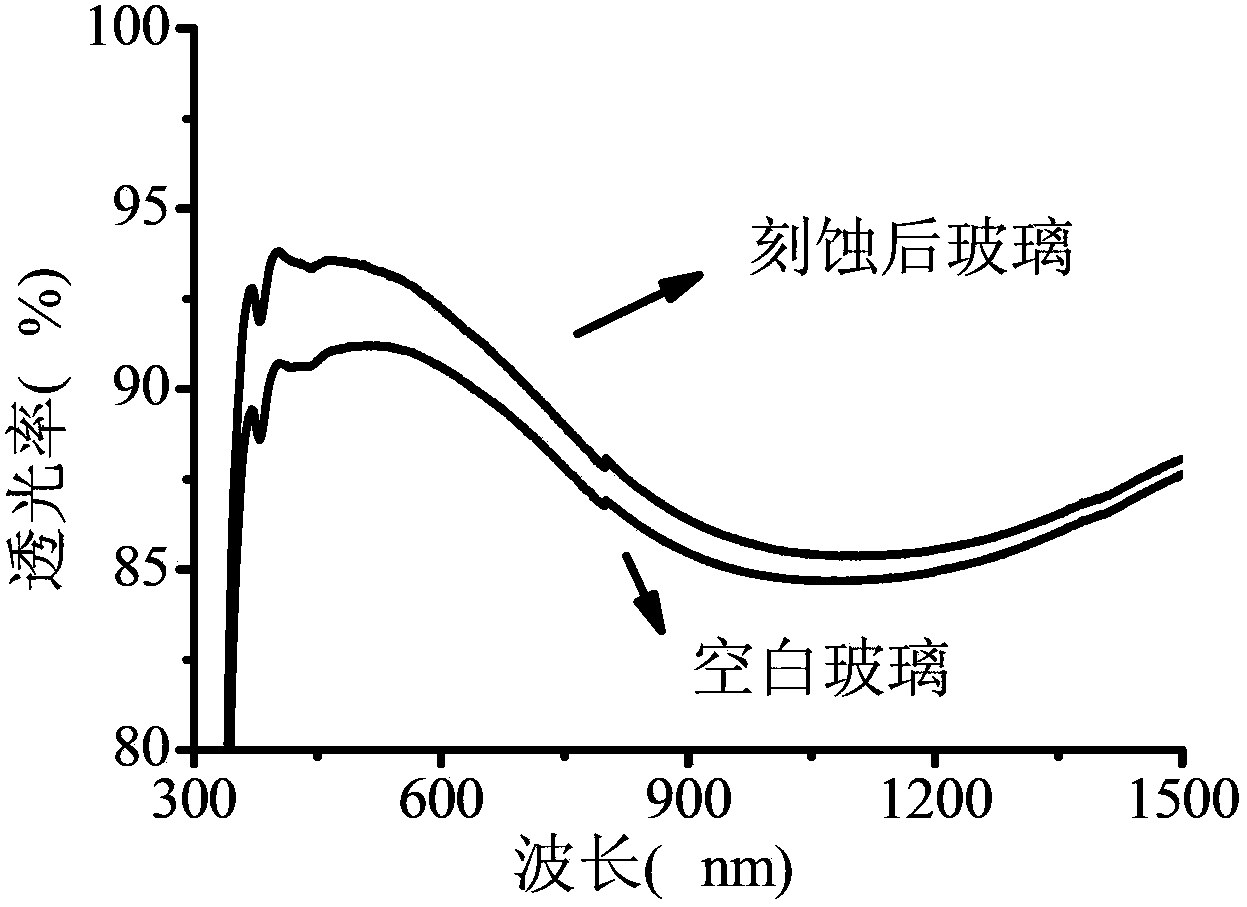

Embodiment 3

[0052] Add 30mL of fluorosilicic acid aqueous solution with a concentration of 1.00mol / L to a 500mL container with a polytetrafluoroethylene material as the inner liner, and wash the cleaned glass sheet (the size of the glass sheet is 2.5 cm (width) × 7.5 cm (length) × 0.1 cm (thickness)) placed on the four-legged support; put the glass piece together with the support into a container with polytetrafluoroethylene as the inner liner, and the glass piece is suspended horizontally in the container in the aqueous solution of fluorosilicic acid Above, cover the lid of the container, put the container with the lid into the hydrothermal kettle, cover the lid of the hydrothermal kettle and tighten it, in a sealed state, put the hydrothermal kettle into the constant temperature box, at a temperature of The glass sheet was etched at 5°C for 48 hours, and a layer of porous structure layer with a thickness of 48nm extending from the surface of the glass sheet to the inside of the glass she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com