Core/shell type tetragonal titanium oxide particle water dispersion, making method, UV-shielding organic silicone coating composition and coated article

A tetragonal system, titanium oxide technology, applied in titanium compounds, chemical instruments and methods, coatings, etc., can solve the problem of unknown method of coating thickness and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

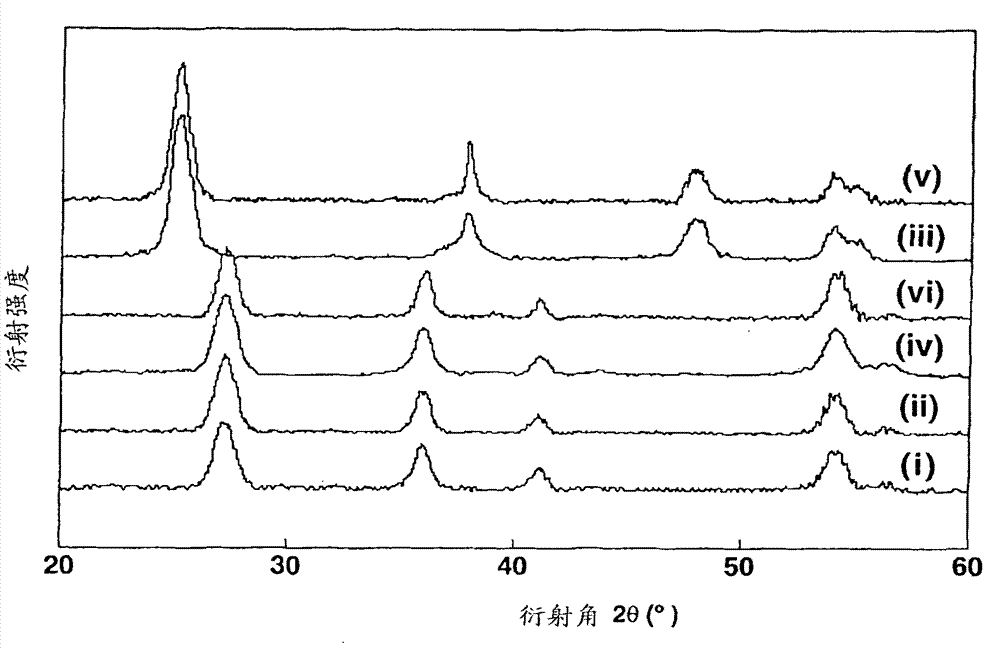

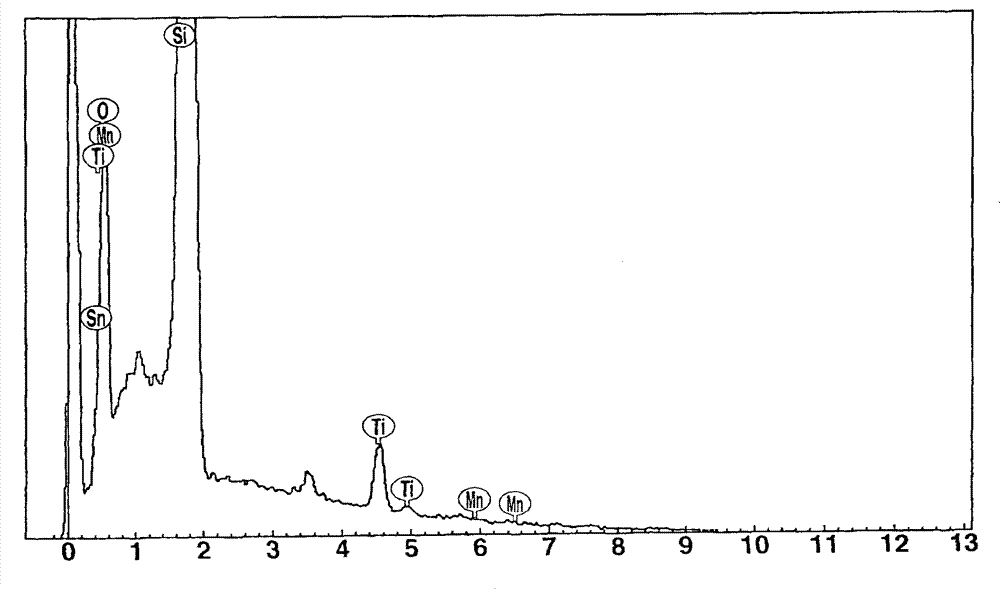

[0099] The second embodiment is a method for preparing an aqueous dispersion of core / shell tetragonal titanium oxide particles in which tin and manganese are solid-solution bound, the method comprising steps (A)-(D) described in detail below.

[0100] Step (A)

[0101] In step (A), an aqueous dispersion of tetragonal titanium oxide nanoparticles in which tin and manganese are bound in solid solution is firstly prepared. There is no particular limitation on the technique for preparing the aqueous dispersion. In a preferred procedure, starting materials including titanium compounds, tin compounds, manganese compounds, alkaline substances and hydrogen peroxide are reacted in an aqueous dispersion medium to form a solution of peroxytitanate containing tin and manganese, for which A hydrothermal reaction is carried out to obtain an aqueous dispersion of tetragonal titanium oxide nanoparticles in which tin and manganese are solid-solution bound.

[0102] The preceding stage of t...

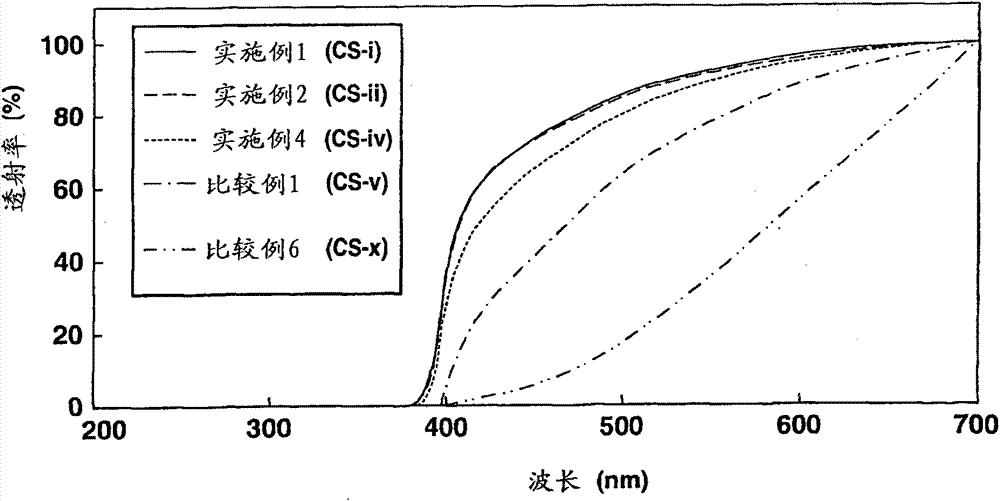

Embodiment

[0197] Examples and comparative examples are given below by way of illustration and not limitation.

[0198] All parts are by weight unless otherwise indicated. The reactants were purchased from chemical suppliers including Wako Pure Chemical Industries, Ltd. (abbreviated as Wako) and Shin-Etsu Chemical Co., Ltd. (abbreviated as Shin-Etsu).

Synthetic example 1

[0201] Preparation of titanium oxide dispersion (i) (relative to 100 mol% titanium, 4 mol% tin and 0.5 mol% manganese)

[0202] To 66.0 g of a 36% by weight titanium (IV) chloride aqueous solution (TC-36 manufactured by Ishihara Sangyo Kaisha, Ltd.) were added 1.8 g of tin (IV) chloride pentahydrate (Wako) and 0.12 g of chlorine Manganese(II) tetrahydrate (Wako). They were mixed well and diluted with 1,000 g of deionized water. To this metal salt aqueous solution mixture, 300 g of 5% by weight ammonia water (Wako) was gradually added to neutralize and hydrolyze to obtain a precipitate of titanium hydroxide containing tin and manganese. The titanium hydroxide slurry was pH 8. The precipitate of titanium hydroxide was deionized by repeated addition of deionized water and decantation. To the deionized titanium hydroxide precipitate containing tin and manganese, 100 g of 30% by weight aqueous hydrogen peroxide (Wako) was gradually added, and stirring was continued at 60° C. for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com