Method for producing ultra-fine grains on surface layer of thick/ultra-thick low-alloy steel plate

A low-alloy steel and manufacturing method technology, which is applied in the field of ultra-fine-grained surface layer of low-alloy steel thick plate/extra-thick plate, can solve the problems of hindering crack propagation, high heat in the core, and not obvious refining effect, etc. To achieve the effect of surface structure, good surface toughness at low temperature and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

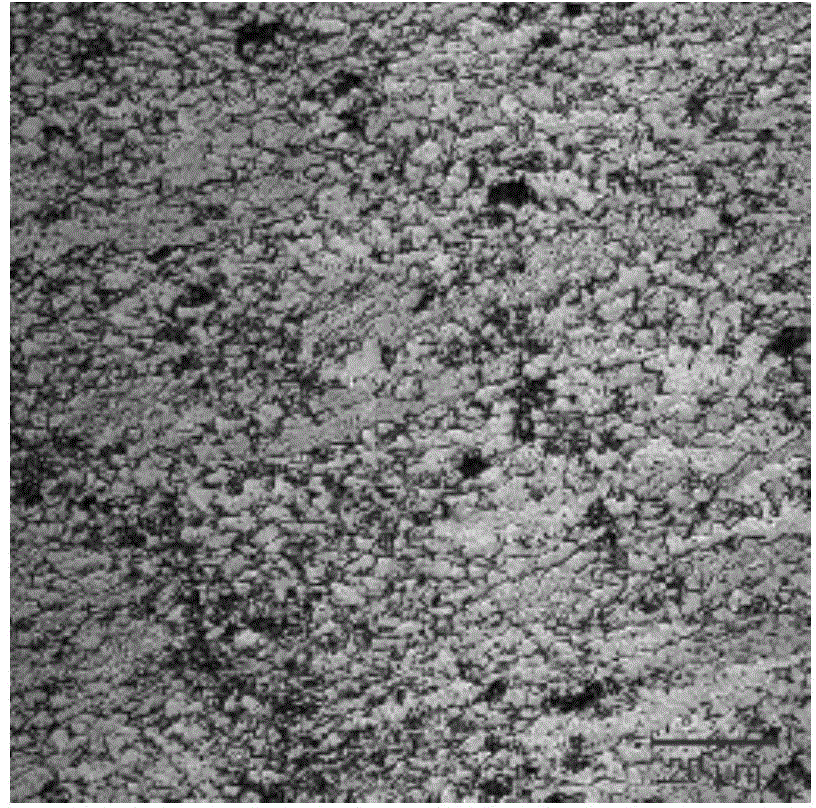

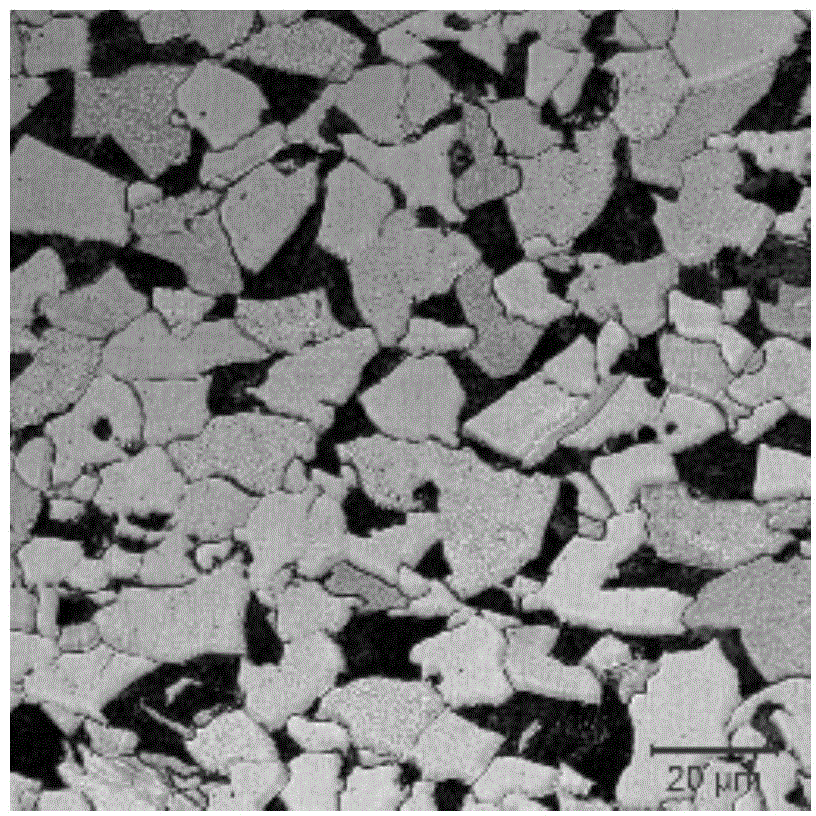

Embodiment 1

[0017] The Q345 continuous casting slab with a thickness of 150mm is used, and the chemical composition is shown in Table 1, and a thick plate with a thickness of 40mm is produced. The continuous casting slab is heated to 1180°C, soaked for 30 minutes, and then released from the furnace. After descaling by high-pressure water, the first-stage rolling is carried out. The pass reduction is 18-22mm. The final rolling temperature of the first stage is 1060°C. The thickness of the intermediate slab is is 90mm. The intermediate slab is rapidly cooled at 10°C / s by the immediate rapid cooling device next to the machine, and the surface temperature of the slab drops to 550°C when it exits the cooling zone, and the second-stage rolling is carried out when the slab temperature reaches 900°C after fully reddening. The rolling reduction in the second stage is 8-15mm, and after rolling for 2 passes, the slab temperature is 880°C. At this time, the slab is cooled rapidly again. When leaving...

Embodiment 2

[0019] The Q345 continuous casting slab with a thickness of 150mm is used, and the chemical composition is shown in Table 1, and a thick plate with a thickness of 40mm is produced. The continuous casting slab is heated to 1100°C, soaked for 30 minutes, and then released from the furnace. After descaling by high-pressure water, the first-stage rolling is carried out. The reduction in each pass is 18-22mm. The final rolling temperature of the first stage is 1060°C. The thickness of the intermediate slab is is 90mm. The intermediate slab is rapidly cooled at 10°C / s by the immediate rapid cooling device next to the machine, and the surface temperature of the slab drops to 350°C when it exits the cooling zone, and the second-stage rolling is carried out when the slab temperature reaches 850°C after fully reddening. The rolling reduction in the second stage is 8-15mm, and after rolling for 2 passes, the slab temperature is 880°C. At this time, the slab is cooled rapidly again. When...

Embodiment 3

[0021] The Q420 continuous casting slab with a thickness of 320mm is used, and the chemical composition is shown in Table 1, and the extra-thick plate with a thickness of 80mm is produced. The continuous casting slab is heated to 1200°C, soaked for 60 minutes, and then released from the furnace. After descaling by high-pressure water, the first-stage rolling is carried out. The reduction in each pass is 25-35mm. After 5 passes, the first-stage rolling ends. The final rolling temperature of the first stage is 1080°C, and the thickness of the intermediate billet is 160mm. The intermediate slab is rapidly cooled at 15°C / s by the immediate rapid cooling device next to the machine, and the surface temperature of the slab drops to 350°C when it exits the cooling zone, and the second-stage rolling is carried out when the slab temperature reaches 910°C after fully reddening. The total number of rolling passes in the second stage is 5 times, and the reduction in each pass is 12-20mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com