Electrochemical composite deposition manufacturing method and device for laser light tube electrode

A technology for manufacturing devices and manufacturing methods, which is applied in the field of electrochemical composite deposition manufacturing of laser light tube electrodes, can solve problems such as affecting the electrodeposition process, unfavorable localized deposition of metal ions, and unsatisfactory electrochemical reaction composite efficiency, etc., to achieve improved Effects of processing quality, improving localization selectivity, and reducing deposition stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

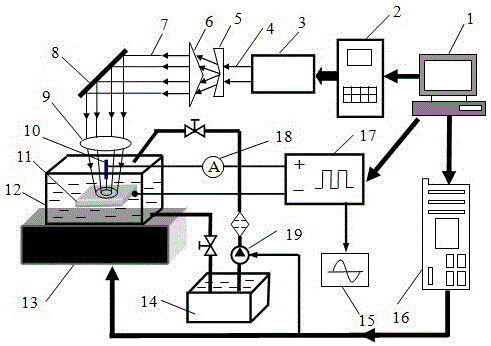

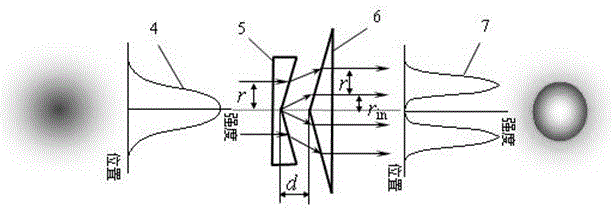

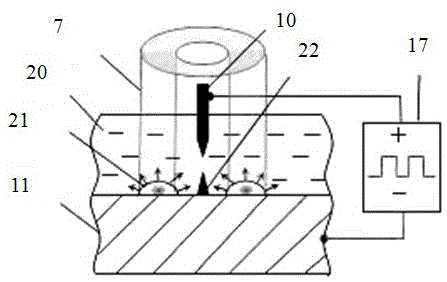

[0029] The electrochemical composite deposition manufacturing method of the laser light tube electrode processes the laser beam output by the laser through the beam modulation system, and modulates its spatial energy distribution from a solid circular laser beam to a ring-shaped hollow laser beam with a central light intensity of zero; a ring-shaped hollow laser beam The laser beam and the electrochemical tool anode located in the center of the ring form a composite processing system, that is, a non-solid laser light tube electrode is formed on the periphery of the electrochemical tool anode, and the plasma expansion and expansion effect generated by laser irradiation is used to control the laser light tube electrode. The electrochemical deposition inside produces compression impact, removes deposition stress, discharges cathode reaction gas, improves material density, and realizes high-quality electrochemical composite deposition processing, repair and surface performance enhan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com