Heat recovery composite energy system for hospital buildings

A composite energy and heat recovery technology, applied in energy recovery systems for ventilation and heating, household heating, air conditioning systems, etc., can solve the problems of power consumption, water production rate cannot be guaranteed, occupy a large area of space, etc., to meet the heat requirements Water usage requirements, ease of management and maintenance, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

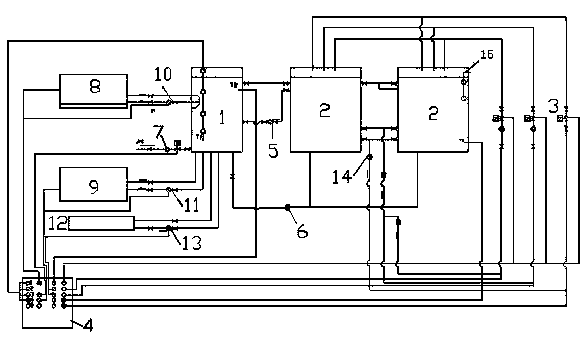

[0012] Such as figure 1 Shown: a heat recovery composite energy system for hospital buildings, which is connected in turn by a ground source heat pump air conditioning system, a heating water tank 1, two hot water storage tanks 2, a return water solenoid valve 3 and a control cabinet 4, and the heating water tank 1 and The hot water replenishment pump 5 and the hot water circulation pump A 6 are respectively connected between the hot water storage tanks 2, and the frequency conversion booster pump 14 is connected between the hot water storage tank 2 and the control cabinet 4. A position controller 15, a water inlet solenoid valve 7 is connected between the heating water tank 1 and the control cabinet 4, and the ground source heat pump air conditioning system is a combined system of a partial heat recovery ground source heat pump unit 9 and a full heat recovery ground source heat pump unit 8; The heat recovery ground source heat pump unit 9 is connected to the heating water tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com