Method for detecting large-caliber large-relative-aperture parabolic reflector surface shape error

A technology of relative aperture and mirror surface, applied in the field of optical testing, can solve the problems of high price, strict requirements for assembly and adjustment accuracy, and difficulty in manufacturing high-precision flat mirrors, to reduce hardware requirements, improve lateral resolution, reduce The effect of precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

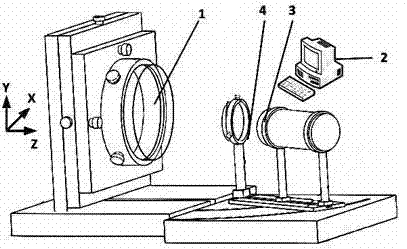

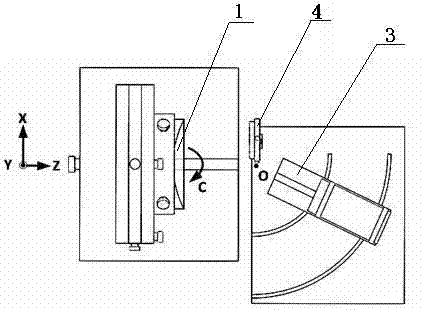

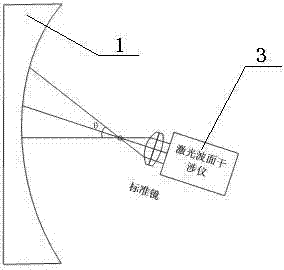

[0030] see figure 1 and figure 2 , the detection device used in the inventive method comprises laser wavefront interferometer 3, measured parabolic reflector 1, standard plane reflector 4 and main control computer 2, laser wavefront interferometer 3, measured parabolic reflector 1, standard The plane mirrors 4 are all operated by their respective adjustment mechanisms.

[0031] The specific device is a known structural combination;

[0032] The movement of the laser wavefront interferometer is controlled by its adjustment mechanism. The center of rotation of the adjustment mechanism is O, and the focus of the laser wavefront interferometer 3 coincides with its rotation center O through the action of the adjustment mechanism; The wave surface interferometer 3 rotates at a certain angle around its focal point (ie, the center of rotation O).

[0033] The adjustment mechanism of the parabolic mirror 1 under test includes an X-axis motion adjustment platform, a Y-axis motio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com